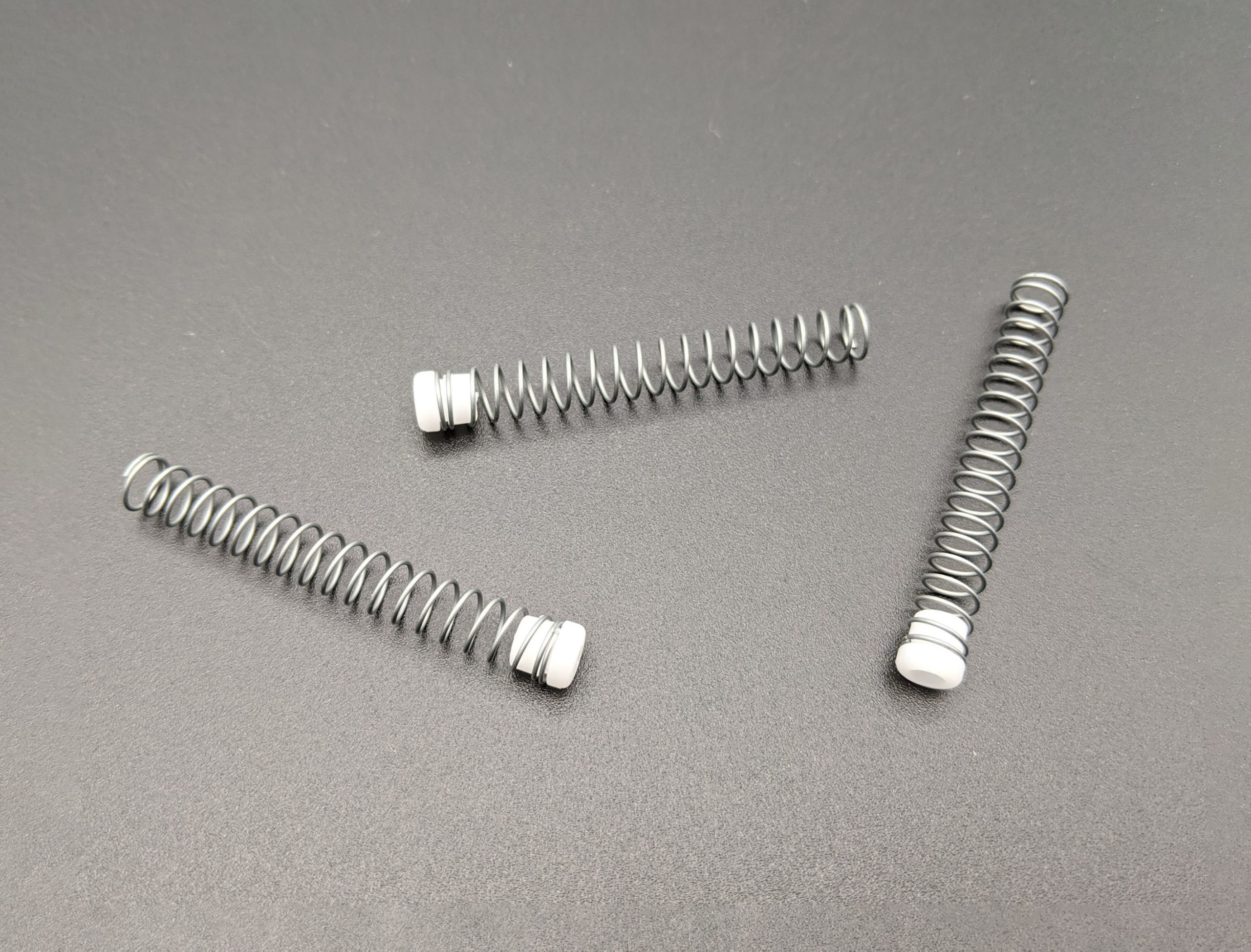

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs are often taken for granted. We see them in our daily lives, from the simple coil springs in our pens to the complex

In the world of mechanical engineering, springs are often taken for granted. We see them in our daily lives, from the simple coil springs in our pens to the complex suspension systems in our cars. But have you ever stopped to think about the intricate design and functionality of these seemingly ordinary components? Today, we'll delve into the fascinating world of torsion springs, specifically focusing on a unique type known as the Z-st torsion spring. These springs, characterized by their compact size and remarkable ability to generate high torque, are crucial in countless applications, making them true unsung heroes of precision engineering.

Before we dive into the specifics of Z-st torsion springs, let's first understand what a torsion spring is. In its simplest form, a torsion spring is designed to store and release energy through twisting or rotational motion. It's a bit like a spring-loaded door hinge, where the spring resists the door's opening and closing, providing a smooth, controlled movement. Z-st torsion springs, however, are a unique breed. They are characterized by their compact, Z-shaped design, making them highly space-efficient. This Z-shaped configuration allows them to pack a significant punch in terms of torque generation, offering high force output within a relatively small footprint.

What makes Z-st torsion springs so special? The answer lies in their exceptional ability to generate high torque within limited space. This ability is achieved through their unique design and the way they are manufactured. The Z-shaped configuration, with its sharp bends, effectively concentrates the spring's force, allowing it to exert a significant twisting force despite its relatively small size. This characteristic makes Z-st torsion springs incredibly versatile and valuable in numerous applications where space is a premium, yet high torque is essential.

The diverse world of Z-st torsion springs is vast and intriguing. Their unique properties have found applications in various industries, contributing to the smooth and efficient operation of countless devices. Here are just a few examples:

Imagine the intricate mechanisms inside your car, from the steering wheel to the windshield wipers. Z-st torsion springs play a crucial role in ensuring these components operate smoothly and efficiently. Their compact size and high torque output make them perfect for fitting into tight spaces, while their ability to withstand repeated cycles ensures long-lasting performance. Z-st torsion springs are often found in power steering systems, window regulators, and various other automotive components where precise control and durability are paramount.

In the demanding world of aerospace and aviation, every component needs to be light, strong, and reliable. Z-st torsion springs are perfect for such applications, providing high torque with minimal weight and footprint. They are often used in aircraft control surfaces, landing gear systems, and other critical components that require robust and precise movement. Their ability to withstand extreme temperature fluctuations and high vibration levels makes them ideal for the challenging environments experienced in aerospace applications.

The medical field relies on precision engineering for its instruments and devices. Z-st torsion springs play a crucial role in ensuring the accuracy and reliability of many medical devices. For example, they are used in surgical tools, medical implants, and diagnostic equipment, where precise movement and control are essential. Their small size and ability to generate precise forces make them ideal for these applications, contributing to the safety and effectiveness of medical procedures.

In the world of consumer electronics, Z-st torsion springs are often found in devices where space is limited, but a smooth and controlled movement is crucial. They are commonly used in cell phone buttons, laptop hinges, and other small, intricate mechanisms, providing a responsive and reliable feel. The compact size and high torque output of Z-st torsion springs make them perfect for these demanding applications, contributing to the seamless functionality of our beloved gadgets.

The manufacturing process of Z-st torsion springs is a testament to the precision and skill involved in creating these high-performance components. It begins with carefully selecting the appropriate spring material, which is typically high-strength steel, ensuring the desired strength, elasticity, and durability. The chosen material is then precisely formed into the characteristic Z-shape using specialized machinery that ensures the tight tolerances and intricate geometry required for optimal performance.

The manufacturing process often involves heat treatment to further enhance the spring's strength and resilience. This involves carefully controlling the temperature and duration of heating and cooling cycles, ensuring the spring achieves its desired properties. The final stage of manufacturing involves rigorous quality control checks, ensuring each Z-st torsion spring meets the stringent specifications for its intended application.

Selecting the right Z-st torsion spring for a particular application is crucial. It requires considering several factors, including:

Working with experienced spring manufacturers is essential, as they can provide valuable guidance and support in selecting the optimal Z-st torsion spring for your specific needs. They can help you understand the nuances of spring design and material selection, ensuring you choose the perfect spring for your application.

The world of Z-st torsion springs is constantly evolving. As technology advances, so too do the demands for these tiny but mighty components. Engineers and manufacturers are constantly exploring new materials, designs, and manufacturing techniques to push the boundaries of Z-st torsion spring capabilities. This ongoing innovation ensures that Z-st torsion springs will continue to be a vital part of countless engineering marvels for years to come.

Z-st torsion springs, with their compact size, high torque output, and exceptional durability, are truly the unsung heroes of precision engineering. They are essential in countless applications, driving the smooth and efficient operation of everything from cars to medical devices and consumer electronics. As technology continues to advance, Z-st torsion springs will undoubtedly play an even greater role in shaping the future of engineering and innovation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.