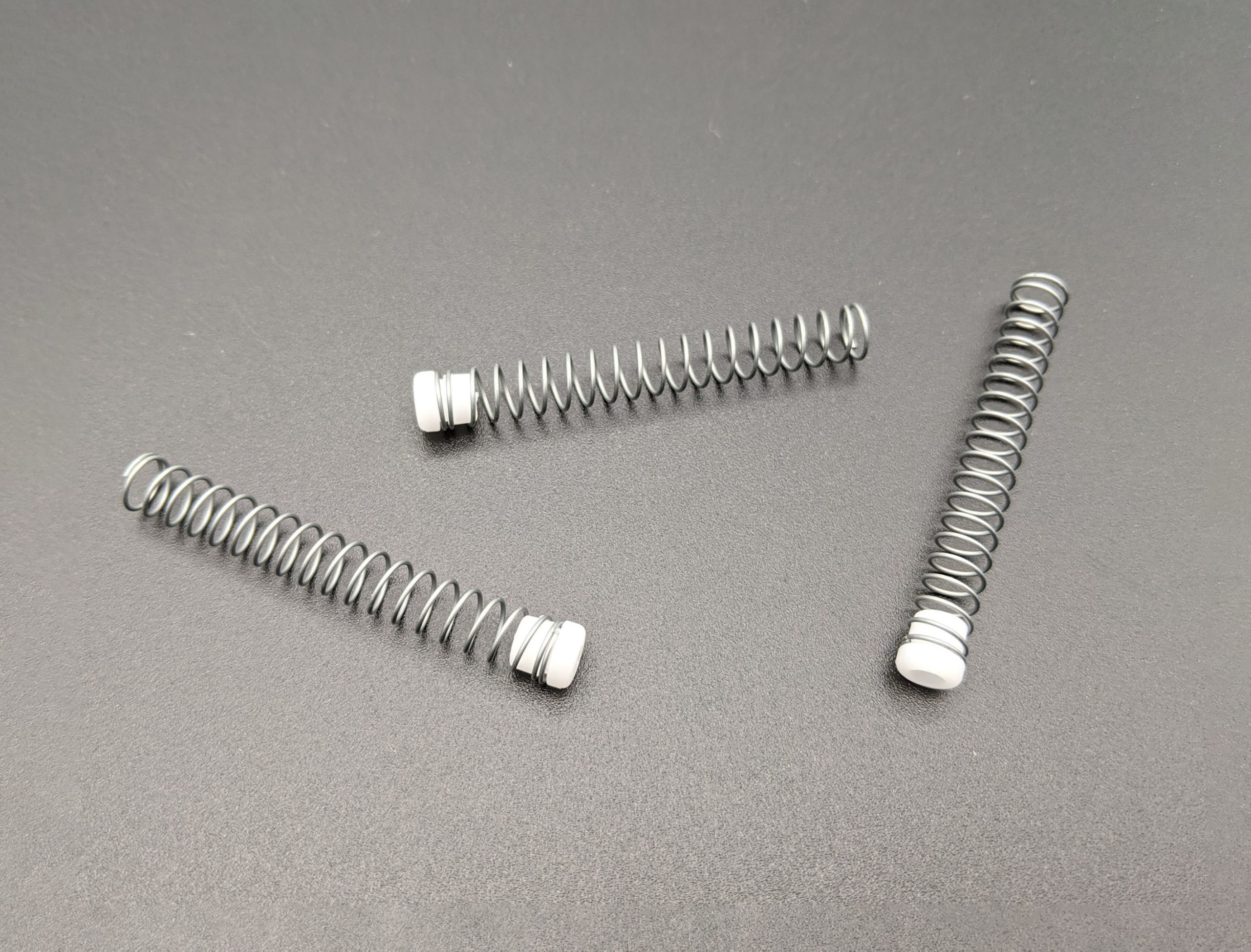

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Wave springs, also known as wave washers, are a type of spring that has gained significant popularity due to their unique characteristics. They offer a compact design, high spring force,

Wave springs, also known as wave washers, are a type of spring that has gained significant popularity due to their unique characteristics. They offer a compact design, high spring force, and long fatigue life, making them ideal for various applications. This article provides a comprehensive overview of wave springs, covering their design, materials, advantages, and diverse applications.

Wave springs, also known as wave washers, are a type of spring that has gained significant popularity due to their unique characteristics. They offer a compact design, high spring force, and long fatigue life, making them ideal for various applications. These springs are often preferred over traditional coil springs due to their ability to provide greater force in a smaller space.

Unlike traditional helical springs, wave springs are made from a single piece of spring material that has been carefully formed into a series of waves. This unique design provides them with several advantages over conventional springs. These springs are typically made from a variety of materials, including stainless steel, music wire, phosphor bronze, and beryllium copper, each with its own specific properties. The material selection depends on the desired spring characteristics, such as load capacity, temperature resistance, and corrosion resistance.

Wave springs offer a range of benefits that make them attractive for many applications. They are known for their high load capacity, even in small spaces, and can withstand significant loads without collapsing. Their unique design provides them with excellent fatigue resistance, resulting in a longer service life than many other spring types. Wave springs are also highly resistant to corrosion and can operate under a wide range of temperatures, making them suitable for demanding environments.

The versatility of wave springs makes them suitable for various applications across numerous industries. They are commonly used in the following:

Wave springs come in various configurations to meet different design requirements. Some of the common types include:

When selecting wave springs for an application, several factors should be considered:

Wave springs are a versatile and innovative spring design that has revolutionized various industries. Their compact design, high load capacity, long fatigue life, and wide range of applications make them a valuable option for engineers and designers. As technology advances, we can expect to see even more innovative and specialized wave spring designs emerging to meet the ever-evolving needs of various industries.

In conclusion, wave springs are a powerful and reliable solution for numerous applications, offering advantages over traditional coil springs in many cases. Their compact design, high load capacity, long fatigue life, and resistance to corrosion make them a valuable asset to engineers and designers across various industries. As technology continues to advance, wave springs are poised to play an even greater role in shaping the future of spring technology.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.