Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Wave springs, also known as wave washers or Belleville springs, are a unique type of spring characterized by their distinctive wave-like shape. This design offers a variety of advantages over

Wave springs, also known as wave washers or Belleville springs, are a unique type of spring characterized by their distinctive wave-like shape. This design offers a variety of advantages over traditional helical springs, making them a valuable option in a wide range of applications. Wave springs provide a high spring rate in a compact footprint, making them ideal for situations where space is limited. They also excel in handling high loads, withstanding significant compressive forces without deformation. This article delves into the fascinating world of wave springs, exploring their construction, advantages, and diverse applications.

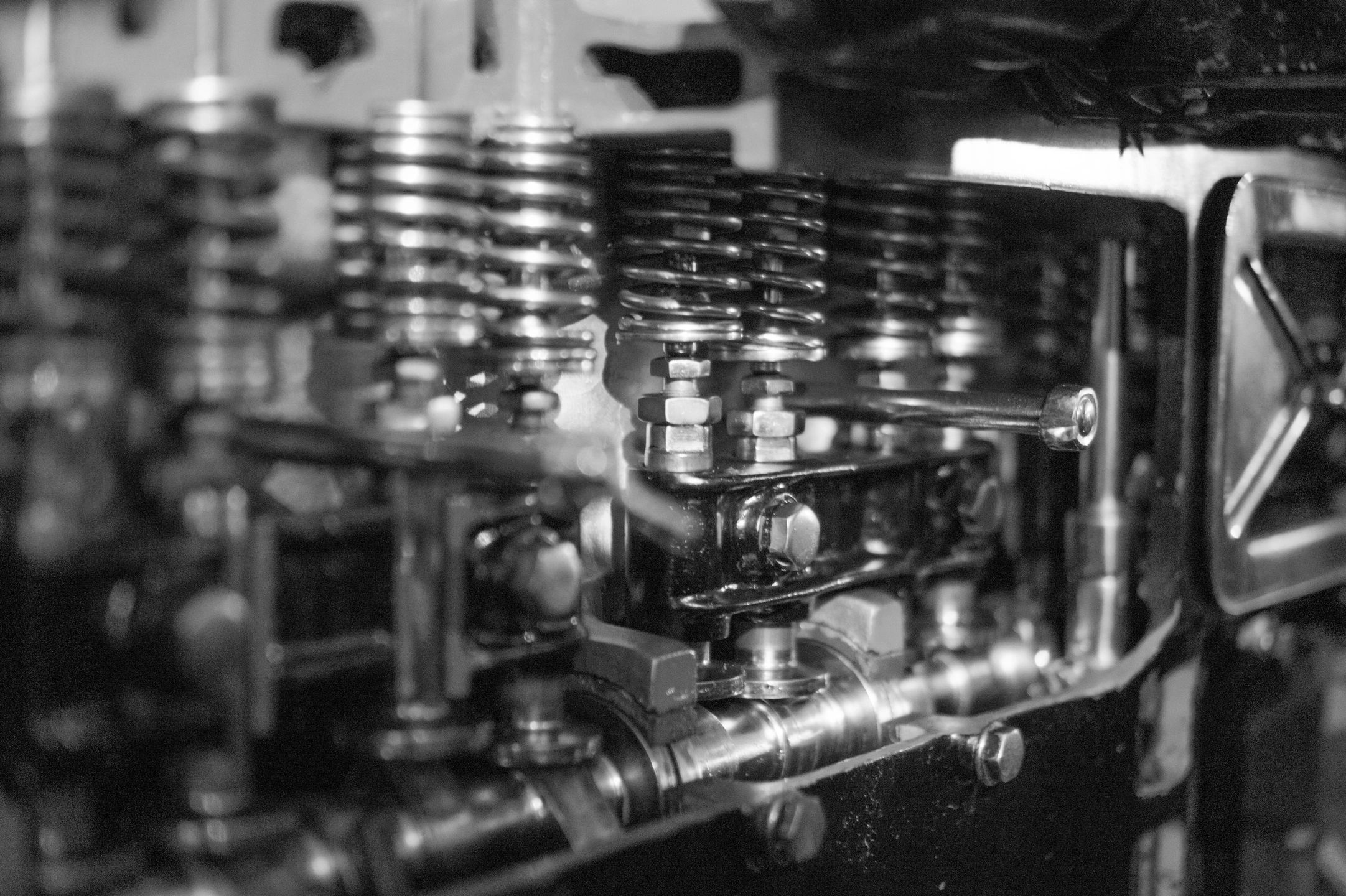

Wave springs are essentially thin, disc-shaped springs with a series of concentric waves or curves along their periphery. These waves are meticulously designed to create a distinct spring effect, where the spring's deflection is directly related to the applied load. Unlike helical springs, wave springs work by bending rather than twisting, resulting in their unique characteristics.

The construction of wave springs involves stacking multiple wave-shaped discs on top of each other. These discs are often made from high-quality materials like spring steel, stainless steel, or other alloys, depending on the application's demands. The material's elasticity and the number of wave discs determine the spring's overall stiffness and load capacity.

The unique design of wave springs grants them a range of advantages that set them apart from conventional helical springs. These benefits include:

Wave springs have found their way into a remarkable array of applications, demonstrating their versatility and effectiveness. Here are some notable examples:

While wave springs offer numerous advantages, it's crucial to consider several factors when selecting the right type for a particular application. These factors include:

Wave springs stand as a testament to ingenuity and innovation in spring technology. Their unique design, offering compact size, high spring rate, and exceptional load capacity, makes them a valuable solution for a wide range of applications. Whether it's in automotive engineering, aerospace exploration, medical devices, or everyday consumer products, wave springs continue to provide reliable and efficient solutions, demonstrating their enduring relevance in a world that demands ever-increasing performance and efficiency.

In conclusion, wave springs represent a remarkable advancement in spring design, offering a blend of strength, compactness, and reliability. Their versatility makes them a valuable asset for a wide array of industries and applications. As technological demands continue to evolve, wave springs are poised to play an increasingly important role in shaping the future of spring technology.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.