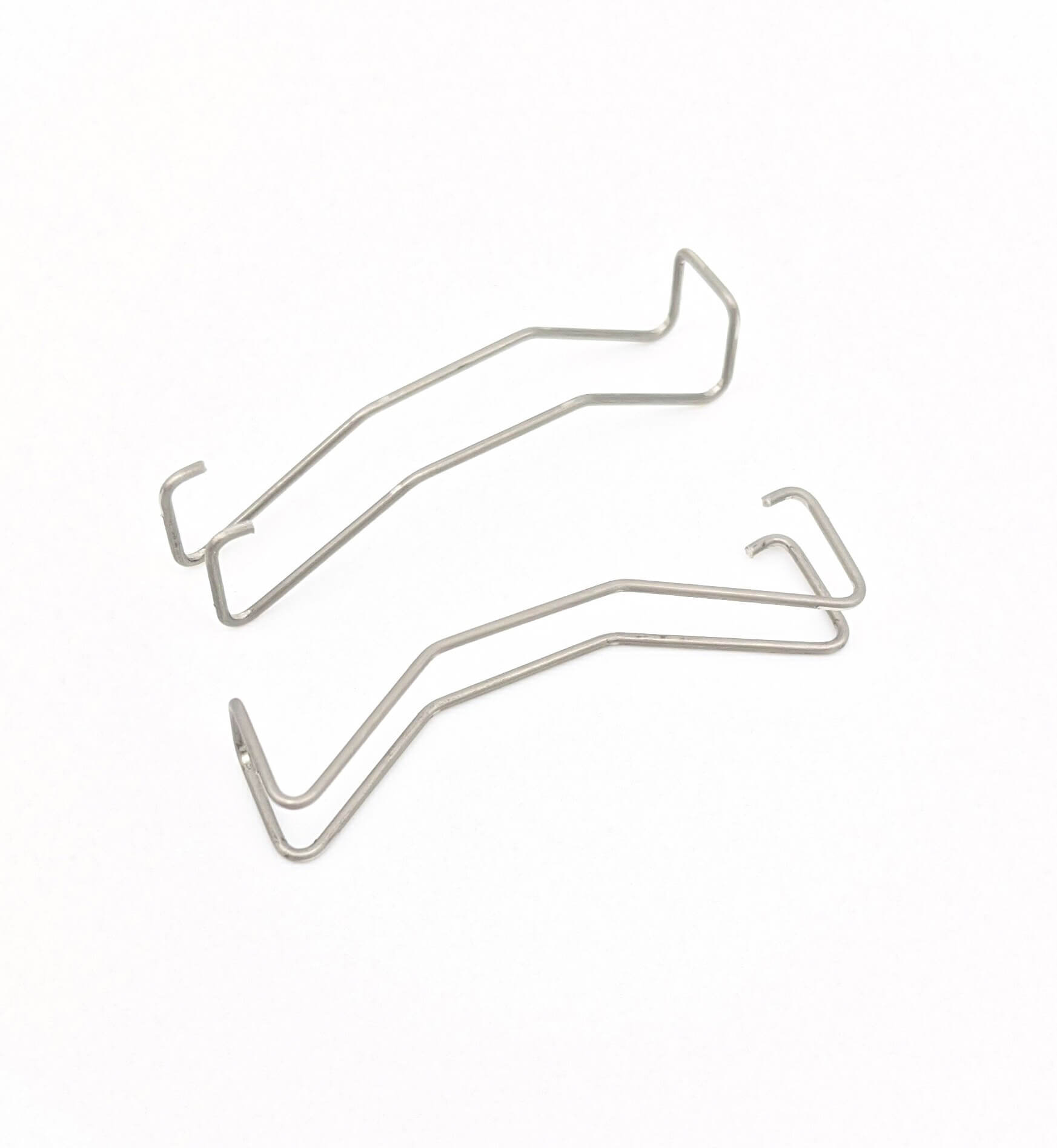

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Wave disc springs, also known as Belleville washers, are a fascinating and surprisingly versatile type of spring that has become increasingly popular in various engineering applications. These deceptively simple, disc-shaped

Wave disc springs, also known as Belleville washers, are a fascinating and surprisingly versatile type of spring that has become increasingly popular in various engineering applications. These deceptively simple, disc-shaped components offer a unique combination of high load capacity, compact size, and consistent performance. Let's delve into the world of wave disc springs and explore their design, functionality, and widespread applications.

Imagine a spring that packs a punch in a tiny package – that's the essence of a wave disc spring. These springs are essentially conical discs with a distinctive wave-like profile on one or both sides. This unique shape is what gives them their exceptional strength and force characteristics.

The magic of a wave disc spring lies in its ability to store and release energy through a combination of bending and compression. As a load is applied, the spring's wave-like profile deforms, storing energy. When the load is removed, the spring returns to its original shape, releasing the stored energy. This simple yet powerful principle is the foundation of their remarkable capabilities.

Compared to traditional coil springs, wave disc springs offer a compelling set of advantages:

The versatility of wave disc springs has led to their adoption across diverse industries and applications:

Selecting the appropriate wave disc spring for your specific application involves considering several factors:

Wave disc springs can be stacked and combined to create custom spring configurations with tailored characteristics. They can be used in series to increase deflection, in parallel to increase load capacity, or in various combinations to achieve specific force-deflection curves.

It's important to note that wave disc springs are typically manufactured from high-quality spring steel, but other materials like stainless steel or alloys can be used depending on the application.

The world of wave disc springs is vast and ever-evolving. There are specialty versions of these springs with additional features like pre-loads, adjustable stiffness, and even custom wave profiles. These variations further enhance their versatility and adaptability.

Wave disc springs are a testament to the ingenuity of engineering. Their compact size, high load capacity, and consistent performance make them a powerful solution for a wide range of design challenges. Whether you're building a precision instrument or a heavy-duty machine, wave disc springs offer a unique combination of strength, reliability, and versatility that can elevate your designs. So, the next time you face a demanding spring application, consider the power of the wave disc spring – it might just be the perfect solution you've been looking for.

Wave disc springs are a powerful tool for engineers looking for compact, high-performance solutions. Their versatility and adaptability make them suitable for a wide range of applications, from automotive and aerospace to industrial machinery and medical devices. As you explore the world of spring design, consider the unique capabilities of wave disc springs and how they can enhance your next project.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.