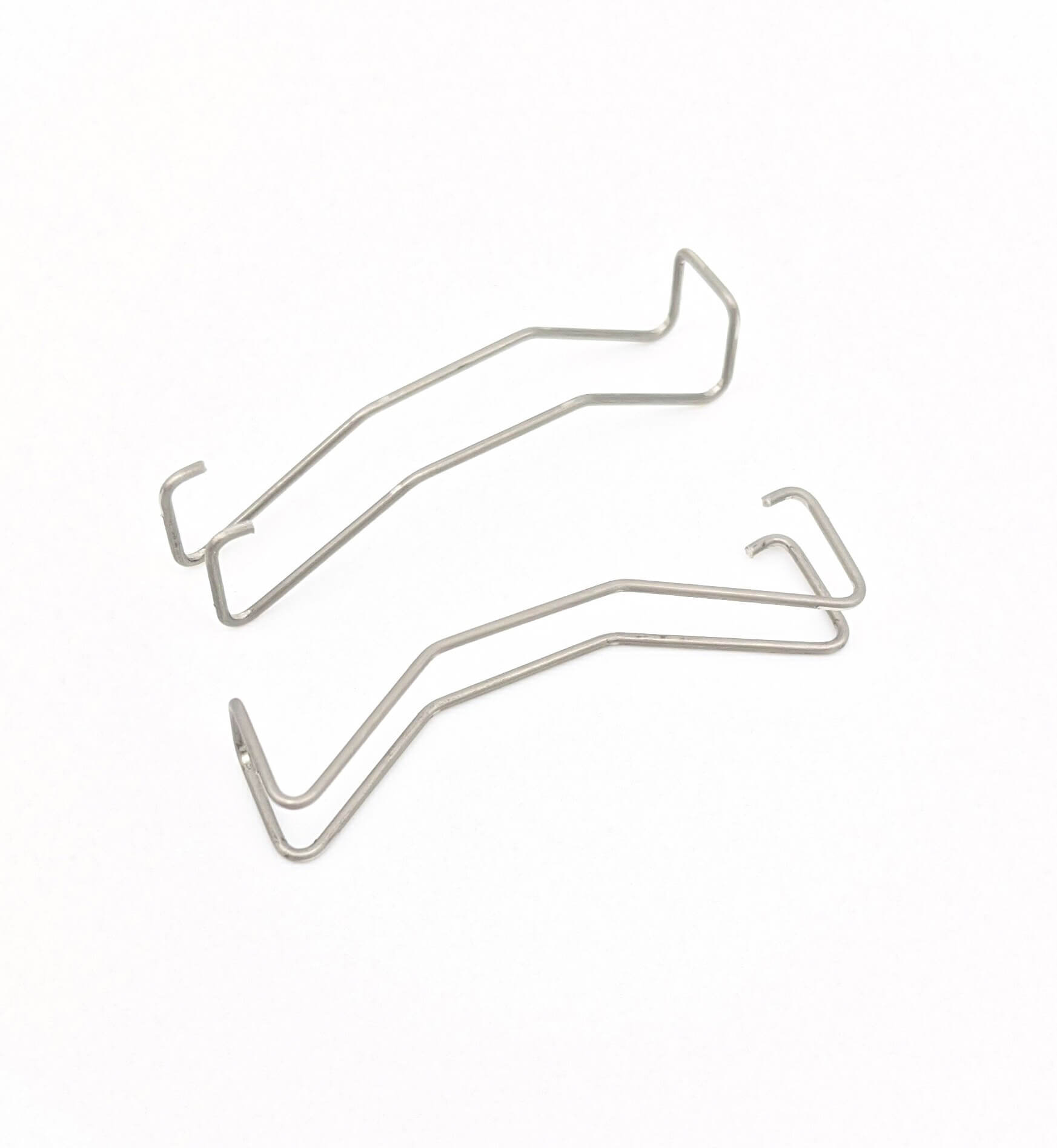

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of precision engineering, springs play a vital role, providing the essential force for countless applications. From delicate medical devices to robust industrial machinery, springs are ubiquitous. And

In the world of precision engineering, springs play a vital role, providing the essential force for countless applications. From delicate medical devices to robust industrial machinery, springs are ubiquitous. And when it comes to the production of high-quality WAV springs, a specialized group of manufacturers steps in to meet the demands of this intricate industry.

WAV springs, short for Wave Springs, are a unique type of spring that boasts a distinct wave-like profile. These springs offer an array of advantages over traditional coil springs, including superior load capacity, increased fatigue resistance, and a smaller footprint. These characteristics make them particularly desirable in applications where space is limited, and reliability is paramount.

WAV springs are crafted from a variety of materials, including stainless steel, music wire, and various alloys, each chosen based on the specific application requirements. The process of manufacturing these springs is complex, demanding meticulous attention to detail and specialized equipment. This is where the expertise of WAV spring manufacturers comes into play.

WAV spring manufacturers are the unsung heroes of many industries. They are the artisans who take raw materials and transform them into intricate components that power our modern world. From automotive and aerospace to medical devices and electronics, these manufacturers play a critical role in ensuring the functionality and longevity of countless products.

The manufacturers of WAV springs not only possess the technical expertise but also understand the intricacies of spring design. They work closely with their clients, understanding their specific needs and challenges, and then tailor the spring design accordingly. This collaborative approach ensures that the final product meets or exceeds the desired performance standards.

Choosing the right WAV spring manufacturer is crucial for any project. There are several key factors to consider when making this decision:

The future of WAV spring manufacturing is bright. As technology continues to advance, the demand for precision engineered components is only going to increase. This will drive innovation in the manufacturing processes, leading to the development of even more sophisticated and reliable springs. Manufacturers will need to embrace new technologies, such as advanced automation, 3D printing, and intelligent material selection, to stay ahead of the curve.

Furthermore, the industry is expected to see a shift towards sustainable manufacturing practices. Manufacturers will need to prioritize energy efficiency, waste reduction, and responsible sourcing of materials. By embracing these principles, they can contribute to a greener and more sustainable future for the industry.

WAV spring manufacturers are the backbone of many industries, providing the essential components that drive innovation and progress. Their dedication to precision engineering, coupled with their commitment to quality and customer satisfaction, makes them an indispensable part of the global manufacturing landscape.

As we look towards the future, the demand for WAV springs is likely to continue to grow. This will present exciting opportunities for manufacturers who are willing to embrace innovation and adapt to the evolving needs of their clients. The quest for precision and reliability will remain at the forefront, and the role of WAV spring manufacturers in meeting these demands will be more important than ever.

In the world of precision engineering, WAV spring manufacturers are the silent heroes, crafting intricate components that power countless industries. Their dedication to quality, precision, and innovation ensures that these springs continue to play a vital role in shaping our modern world. As technology advances and the demand for precision engineered components grows, the role of WAV spring manufacturers will only become more critical, driving progress and enabling new possibilities in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.