Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Wav disc springs, also known as wave springs or Belleville springs, are a fascinating type of mechanical component that offers a unique combination of strength, resilience, and compact design. These

Wav disc springs, also known as wave springs or Belleville springs, are a fascinating type of mechanical component that offers a unique combination of strength, resilience, and compact design. These springs, shaped like a series of waves, are capable of storing and releasing significant amounts of energy, making them a valuable asset in a wide range of applications. Their ability to handle high loads in a small space, coupled with their predictable and consistent performance, has made them essential for numerous industries. In this article, we'll delve into the intricacies of wav disc springs, exploring their design, advantages, and diverse applications, highlighting why they're considered a powerful force in mechanical design.

Imagine a spring that's not a coil, but a series of perfectly formed waves. This is the essence of a wav disc spring. These springs are essentially flat, disc-shaped elements with a unique, wave-like profile. The shape of these waves, along with the material they're made from, determines their spring characteristics. The most common materials for wav disc springs are high-carbon steel and stainless steel, chosen for their strength, durability, and resistance to fatigue. But there's more to these seemingly simple components than meets the eye.

Wav disc springs are known for their exceptional ability to handle high axial loads, meaning they can withstand significant forces pushing or pulling on them. This strength is a result of their unique geometry. The wave-like profile allows them to flex and deform under load, distributing the force evenly across the entire spring. This even distribution of force not only enhances the spring's strength but also increases its fatigue resistance, allowing it to handle repeated loading cycles without losing its effectiveness.

The benefits of using wav disc springs extend beyond their sheer strength and compact design. Here's why these springs have earned a prominent place in modern engineering:

Wav disc springs are widely used in a myriad of applications, ranging from simple everyday objects to complex industrial machinery. Here's a glimpse into their diverse world:

Wav disc springs are far more than just a simple mechanical component. They represent a powerful force in mechanical design, offering a unique blend of strength, resilience, and compact design. Their ability to handle high loads in confined spaces, coupled with their consistent performance and diverse applications, makes them an indispensable part of many industries. Whether it's an aircraft soaring through the sky or a simple household appliance, the power of wav disc springs is quietly but effectively at work, ensuring smooth operation and lasting performance.

In conclusion, wav disc springs are an impressive testament to the ingenuity of engineering. Their ability to deliver exceptional strength and consistent performance in compact configurations makes them a valuable asset for designers and engineers across a wide spectrum of industries. Whether you're working on cutting-edge aerospace technology or a humble household appliance, understanding the capabilities of wav disc springs can open up new possibilities for innovation and efficiency.

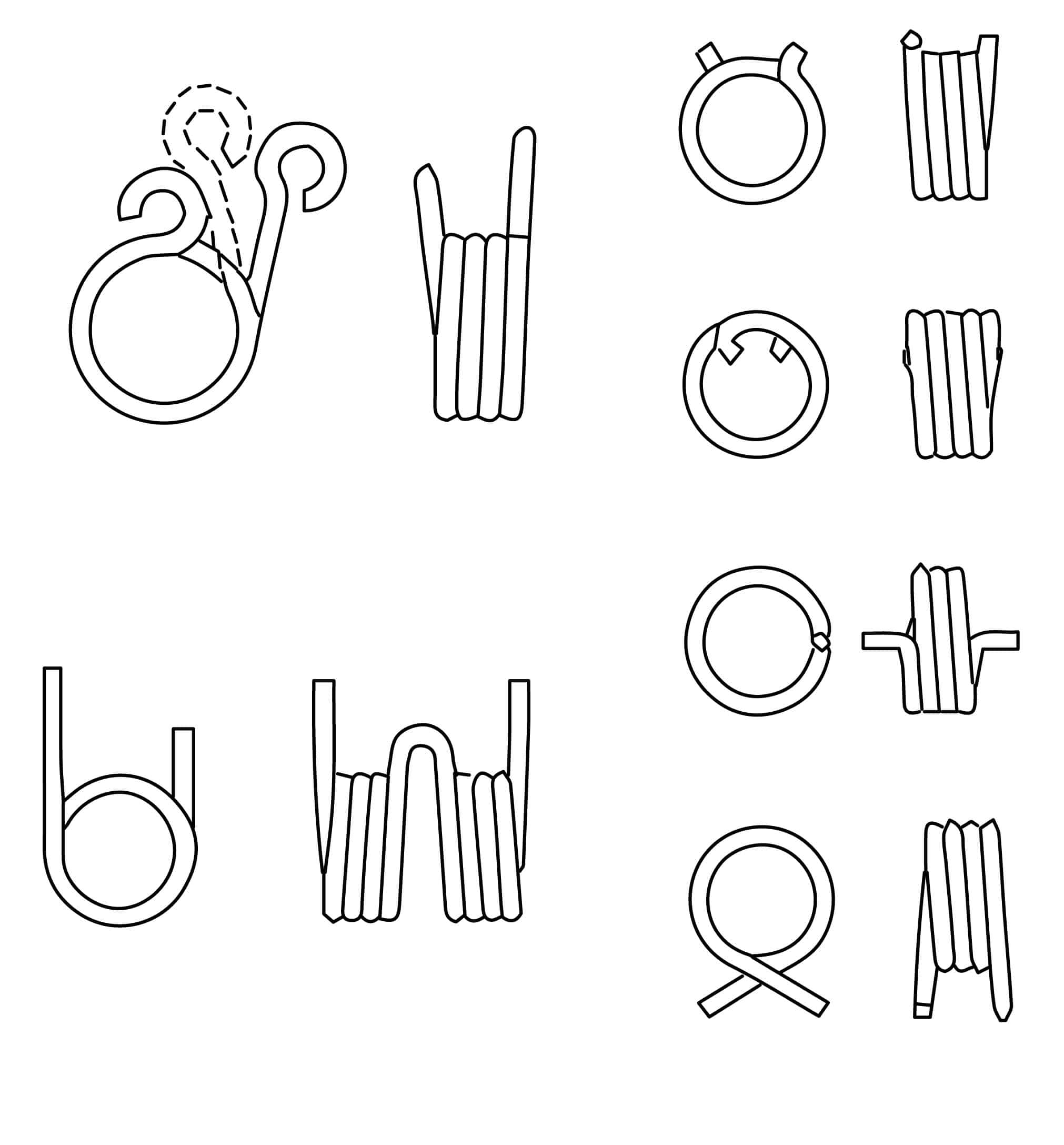

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.