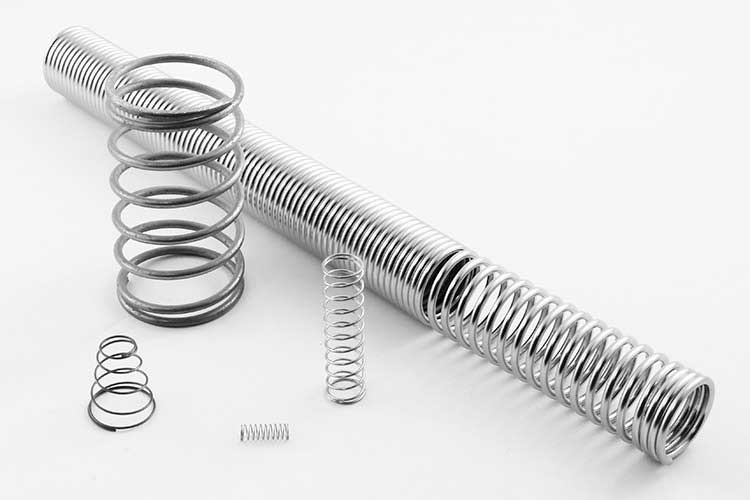

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanics, springs are ubiquitous. They are the silent heroes behind countless everyday objects, from the simple act of opening a door to the complex workings of

In the world of mechanics, springs are ubiquitous. They are the silent heroes behind countless everyday objects, from the simple act of opening a door to the complex workings of a car's suspension. While most of us are familiar with coil springs and leaf springs, there exists a lesser-known but equally important spring design: the V-spring. This article delves into the unique characteristics and applications of V-springs, highlighting their often-overlooked role in various mechanisms.

Unlike their more common counterparts, V-springs are characterized by their distinctive V-shaped configuration. These springs, typically made from hardened steel wire, are known for their ability to provide strong, consistent force over a limited range of motion. The V-shape acts as a lever, magnifying the spring's force, making it particularly suited for applications where precise control and high power are desired. V-springs, due to their unique shape, are often quite robust and possess a resilience that makes them ideal for applications subject to high impact or wear.

The origins of V-springs can be traced back to the fascinating world of antique firearms. Early firearm mechanisms, such as the wheellock, flintlock, and percussion cap locks, relied heavily on V-springs for their operation. These springs were crucial for providing the necessary force to ignite the powder, making them essential for the firing mechanism's functionality. Their resilience and reliable performance, even under extreme conditions, made them a popular choice for these early firearm designs. In addition to firearms, V-springs found their way into antique door latch mechanisms, where their compact design and strong force were ideal for securing doors.

While V-springs may not be as widely recognized as their coil and leaf spring counterparts, they still play a vital role in modern technology. Their compact size, high force output, and robust nature make them perfect for a range of applications, including:

Compared to other spring designs, V-springs offer a distinct set of advantages:

As technology continues to evolve, V-springs are likely to play an even more prominent role in various industries. Their unique properties and versatility make them suitable for a wide range of applications, both traditional and cutting-edge. From the development of new materials to the advancement of manufacturing techniques, the future of V-springs appears bright, offering opportunities for innovation and advancement in diverse fields.

V-springs, despite their understated presence, are vital components in countless mechanical systems. Their unique design and advantageous characteristics make them valuable assets in a variety of applications, from historical firearms to modern precision instruments. As technology continues to advance, V-springs are poised to play an even greater role in shaping the future of mechanical engineering. The next time you encounter a spring, remember the often-overlooked V-spring and its remarkable contributions to the world of mechanics.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.