Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

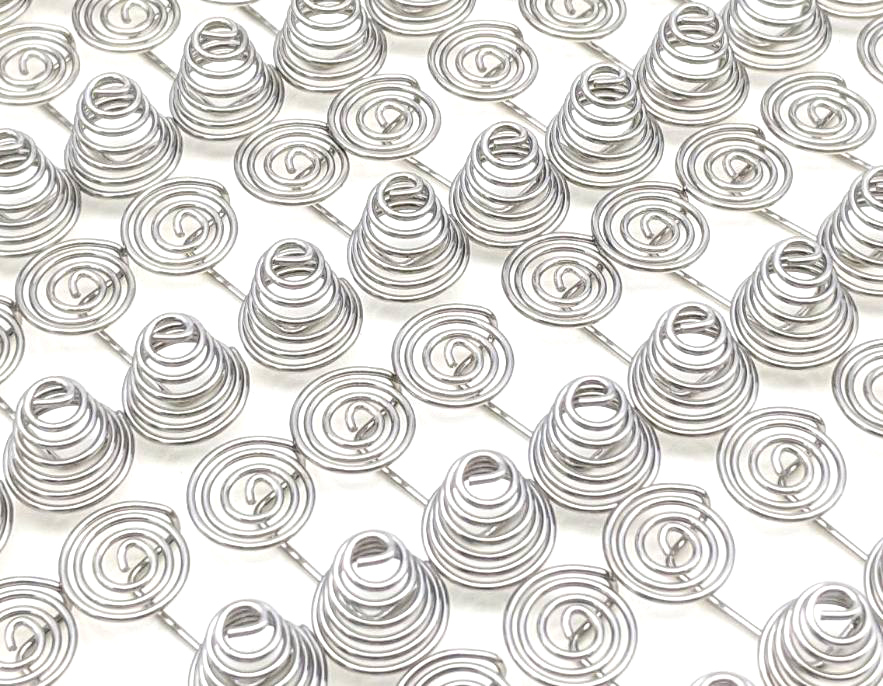

Volute springs, a type of compression coil spring with a conical shape, offer unique advantages over traditional coil springs. Their design allows for greater travel and prevents coil binding, making

Volute springs, a type of compression coil spring with a conical shape, offer unique advantages over traditional coil springs. Their design allows for greater travel and prevents coil binding, making them ideal for applications demanding high load capacities and extended compression. This article delves into the intricacies of volute springs, exploring their structure, advantages, and applications. We'll also touch upon the exciting advancements in volute spring technology that are revolutionizing various industries.

Volute springs, also known as conical springs, are a specific type of compression coil spring designed in a conical shape. Unlike traditional coil springs with uniform spacing between coils, volute springs have a gradually decreasing spacing as they move from the larger diameter end to the smaller diameter end. This unique design provides several advantages that make them valuable in various engineering applications.

Volute springs excel in several aspects compared to their conventional counterparts, making them a preferred choice in many applications. Here are some of the key advantages:

The conical shape of volute springs allows for significantly greater travel compared to traditional coil springs. As the spring compresses, the coils slide past each other with less resistance, enabling a longer compression stroke before the spring reaches its solid height. This is particularly beneficial in applications where extended movement is crucial, such as automotive suspensions, hydraulic actuators, and industrial machinery.

Coil binding, a common issue in traditional coil springs, occurs when the coils are compressed so tightly that they touch and bind together. This binding can lead to reduced performance, increased friction, and premature wear. Volute springs, due to their gradual coil spacing, effectively prevent coil binding, ensuring smooth and efficient operation even under high compression loads.

Volute springs, thanks to their conical design, can handle significantly higher loads compared to traditional coil springs of the same wire diameter. This is because the increasing compression force is distributed more evenly across the coils, maximizing the spring's load capacity. Their robust construction makes them ideal for heavy-duty applications such as industrial presses, lifting equipment, and structural support systems.

The conical shape of volute springs helps to distribute stress more evenly across the coil, minimizing stress concentration at specific points. This reduction in stress concentration improves the fatigue life of the spring, making it more resistant to failure under repeated cycles of compression and extension.

Volute springs find applications in a wide range of industries due to their unique design and performance characteristics. Here are some of the prominent areas where these springs excel:

Volute springs are widely employed in automotive suspensions, particularly for heavy-duty trucks and off-road vehicles. Their ability to handle high loads, provide extended travel, and prevent coil binding makes them a reliable choice for these demanding applications. Volute springs also find use in suspension systems for motorcycles and recreational vehicles.

Volute springs are essential components in industrial machinery, such as presses, hydraulic actuators, and material handling equipment. Their high load capacity and ability to handle repeated compression cycles make them ideal for these demanding applications. Volute springs are also used in industrial automation systems, where precise movement and reliable performance are crucial.

Volute springs are utilized in aerospace applications, particularly in aircraft landing gear and satellite mechanisms. Their lightweight construction, high strength, and resistance to extreme temperatures make them suitable for these demanding environments. The high-quality materials used in aerospace applications also contribute to the long lifespan and reliability of volute springs.

Volute springs find applications in medical devices, such as surgical instruments, prosthetic limbs, and medical equipment. Their biocompatibility, corrosion resistance, and ability to provide controlled movement make them suitable for these sensitive applications. Volute springs are often made from medical-grade materials to meet stringent safety and regulatory standards.

Volute spring technology is constantly evolving, driven by the need for improved performance, reduced weight, and enhanced durability. Here are some notable advancements:

Advancements in material science have led to the development of composite volute springs, which combine the strength of metals with the lightweight properties of composites. These hybrid springs offer improved load capacity, reduced weight, and increased fatigue life, making them suitable for applications where weight is a critical factor. Examples include aerospace, automotive, and sporting goods.

Variable stiffness volute springs, also known as adaptive springs, are designed to change their stiffness based on external factors such as load or temperature. These innovative springs offer greater control and adaptability in applications requiring variable spring rates, such as active suspension systems in vehicles and robotics.

Advancements in micro-fabrication technologies have enabled the development of micro-volute springs, which are incredibly small and precise. These miniature springs are finding applications in microfluidic devices, sensor systems, and other miniaturized technologies. Their small size, high strength, and controlled movement make them ideal for these demanding applications.

Volute springs, with their unique conical design and exceptional performance characteristics, have revolutionized various industries. Their ability to handle high loads, provide extended travel, and prevent coil binding makes them a reliable choice for demanding applications. Ongoing advancements in volute spring technology are continually pushing the boundaries of performance and introducing new possibilities for innovation. As technology continues to evolve, volute springs are poised to play an even more prominent role in shaping the future of engineering and design.

The future of volute spring technology is filled with exciting potential, driven by the growing demand for high-performance, lightweight, and adaptable spring solutions. As new materials, manufacturing techniques, and design innovations emerge, volute springs are certain to play a pivotal role in advancing various industries and shaping the technological landscape of tomorrow.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.