Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

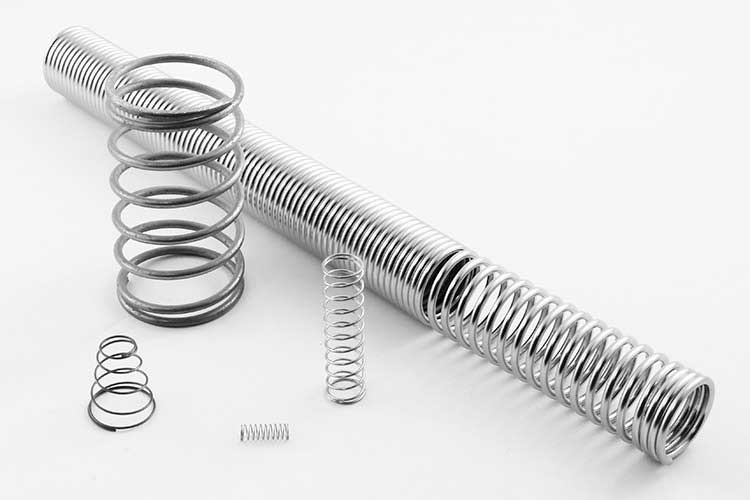

In the realm of mechanical engineering, springs are ubiquitous components that play a crucial role in countless applications. From the delicate hairspring in a watch to the robust coil springs

In the realm of mechanical engineering, springs are ubiquitous components that play a crucial role in countless applications. From the delicate hairspring in a watch to the robust coil springs in a car's suspension, springs are designed to store and release energy, providing essential functions in various systems. Among the many spring designs, the volute spring stands out as a unique and ingenious solution for compression applications, offering advantages that make it a valuable choice in specific scenarios.

A volute spring, also known as a conical spring, is a specialized type of compression coil spring characterized by its conical shape. Unlike conventional cylindrical coil springs, where the coils are parallel, the coils of a volute spring gradually decrease in diameter towards one end, resembling a cone. This unique geometry allows for a longer stroke and a more gradual spring rate, meaning the spring resistance increases more gradually as it is compressed.

The conical design of volute springs offers several advantages that make them ideal for specific applications:

The gradually decreasing coil diameter of a volute spring allows for a longer compression stroke compared to a conventional cylindrical coil spring with the same wire diameter and initial length. This is because the coils have more space to move before they come into contact with each other during compression.

The volute spring's conical shape results in a more gradual spring rate. This means the spring resistance increases more evenly as the spring is compressed, leading to a smoother and more controlled compression.

The conical design of a volute spring reduces the contact stress between the coils during compression. This is because the smaller diameter coils at the end of the spring are compressed first, reducing the pressure on the larger diameter coils.

Volute springs can be more space-efficient than cylindrical springs in certain applications. Because the coils gradually decrease in diameter, they can be packed more tightly, reducing the overall footprint of the spring.

The unique properties of volute springs make them well-suited for a variety of applications, including:

Volute springs are often used in heavy-duty machinery, such as presses, lifts, and construction equipment, where their ability to handle high loads and provide a smooth compression is critical.

Volute springs can be found in automotive applications like suspension systems and engine mounts. Their long stroke and gradual spring rate contribute to a comfortable ride and reduced noise and vibration.

Volute springs are sometimes employed in aerospace applications, where their lightweight design and ability to withstand extreme temperatures make them valuable components.

When designing volute springs, it is crucial to consider several factors:

The choice of material for a volute spring depends on the specific application. Common materials include spring steel, stainless steel, and high-strength alloys. Factors like load capacity, operating temperature, and corrosion resistance need to be considered.

The spring rate is an essential parameter that determines the spring's stiffness. The spring rate of a volute spring can be adjusted by changing the wire diameter, coil diameter, and the number of coils. Accurate calculation of the spring rate is crucial for proper functioning of the spring.

The end configuration of a volute spring can affect its performance and installation. Common end types include closed ends, open ends, and ground ends. The choice of end configuration depends on the application and the desired load transfer characteristics.

Volute springs are typically manufactured using a specialized winding process. This process requires precise control to ensure that the coils are evenly spaced and the spring has the desired conical shape.

Volute springs are a unique and versatile type of compression spring that offers advantages over conventional cylindrical coil springs in specific applications. Their longer stroke, gradual spring rate, reduced contact stress, and space-saving design make them valuable components in heavy-duty machinery, automotive, aerospace, and other industries. By carefully considering design factors like material selection, spring rate, and end configuration, engineers can utilize volute springs to enhance the performance and efficiency of their systems.

In the vast world of springs, the volute spring stands out as a testament to the ingenuity of mechanical design. This unique spring design, with its conical shape and gradual spring rate, offers valuable benefits in applications requiring smooth compression, longer stroke, and reduced contact stress. Whether in heavy-duty machinery, automotive, or aerospace, volute springs continue to play a crucial role in shaping our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.