Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of mechanical engineering, springs have long been the unsung heroes, silently providing elasticity and resilience to countless applications. But what if springs could go beyond their traditional

In the realm of mechanical engineering, springs have long been the unsung heroes, silently providing elasticity and resilience to countless applications. But what if springs could go beyond their traditional role, becoming dynamic and adaptive? Enter the fascinating world of variable stiffness springs, a revolutionary concept that is transforming the way we design and control motion in a myriad of fields.

Imagine a spring that can change its stiffness on demand, seamlessly transitioning from a soft, compliant element to a rigid, resistant one. This is the essence of variable stiffness springs. Unlike conventional springs, which exhibit a fixed stiffness throughout their operating range, variable stiffness springs possess the remarkable ability to adjust their resistance to external forces, offering unparalleled flexibility and adaptability.

The magic of variable stiffness springs lies in their ingenious designs and mechanisms. By incorporating clever engineering principles, they can dynamically alter their spring rate, effectively tailoring their stiffness to suit the specific requirements of the application. Common approaches include:

The ability to dynamically adjust stiffness opens up a plethora of exciting possibilities, revolutionizing the way we approach a wide range of applications:

In robotics, variable stiffness springs hold immense potential for creating robots that move with greater agility and adaptability. By adjusting their stiffness, robots can seamlessly navigate complex environments, interact with objects with varying degrees of fragility, and perform tasks requiring precise control. Imagine robots that can delicately pick up a fragile egg without crushing it, or navigate tight spaces with ease, all thanks to the magic of variable stiffness springs. The possibilities are truly endless.

In automotive applications, variable stiffness springs are paving the way for vehicles that are safer and more comfortable to drive. Imagine suspension systems that automatically adapt to road conditions, providing a smooth ride on bumpy roads while maintaining control on slippery surfaces. Variable stiffness springs can also be incorporated into seat systems, allowing for personalized comfort adjustments based on the driver's preferences and driving style.

The medical field is another area poised to benefit immensely from the versatility of variable stiffness springs. Imagine prosthetics that seamlessly adjust their stiffness to match the wearer's movements and activities. Variable stiffness springs can also be integrated into surgical instruments, providing surgeons with enhanced control and precision during delicate procedures. The potential for improving patient care and outcomes is truly remarkable.

Haptic feedback, the ability to provide tactile sensations to users, is a rapidly growing field. Variable stiffness springs can significantly enhance haptic experiences, allowing users to feel realistic textures and forces in virtual reality applications, gaming, and interactive interfaces. This opens up exciting opportunities for creating more immersive and engaging experiences, making virtual worlds feel more real than ever before.

Variable stiffness springs hold the key to a more natural and intuitive human-robot interaction. By incorporating these springs into robot designs, we can create robots that are more compliant and less likely to cause injury to humans. Imagine robots that can safely collaborate with humans in various tasks, enhancing productivity and fostering a more harmonious relationship between humans and machines.

The field of variable stiffness springs is still in its early stages, but the potential is boundless. As research and development continue, we can expect to see even more innovative applications of this technology emerge. From advanced prosthetics and medical devices to next-generation robotics and human-robot interaction, variable stiffness springs are poised to revolutionize the way we design and control motion, creating a world of enhanced possibilities.

Variable stiffness springs represent a paradigm shift in spring design, allowing for unprecedented flexibility and adaptability. As we delve deeper into the intricacies of this technology, we can expect to see a surge of innovative applications across various sectors. The future is brimming with possibilities, and variable stiffness springs are at the forefront of this exciting technological revolution.

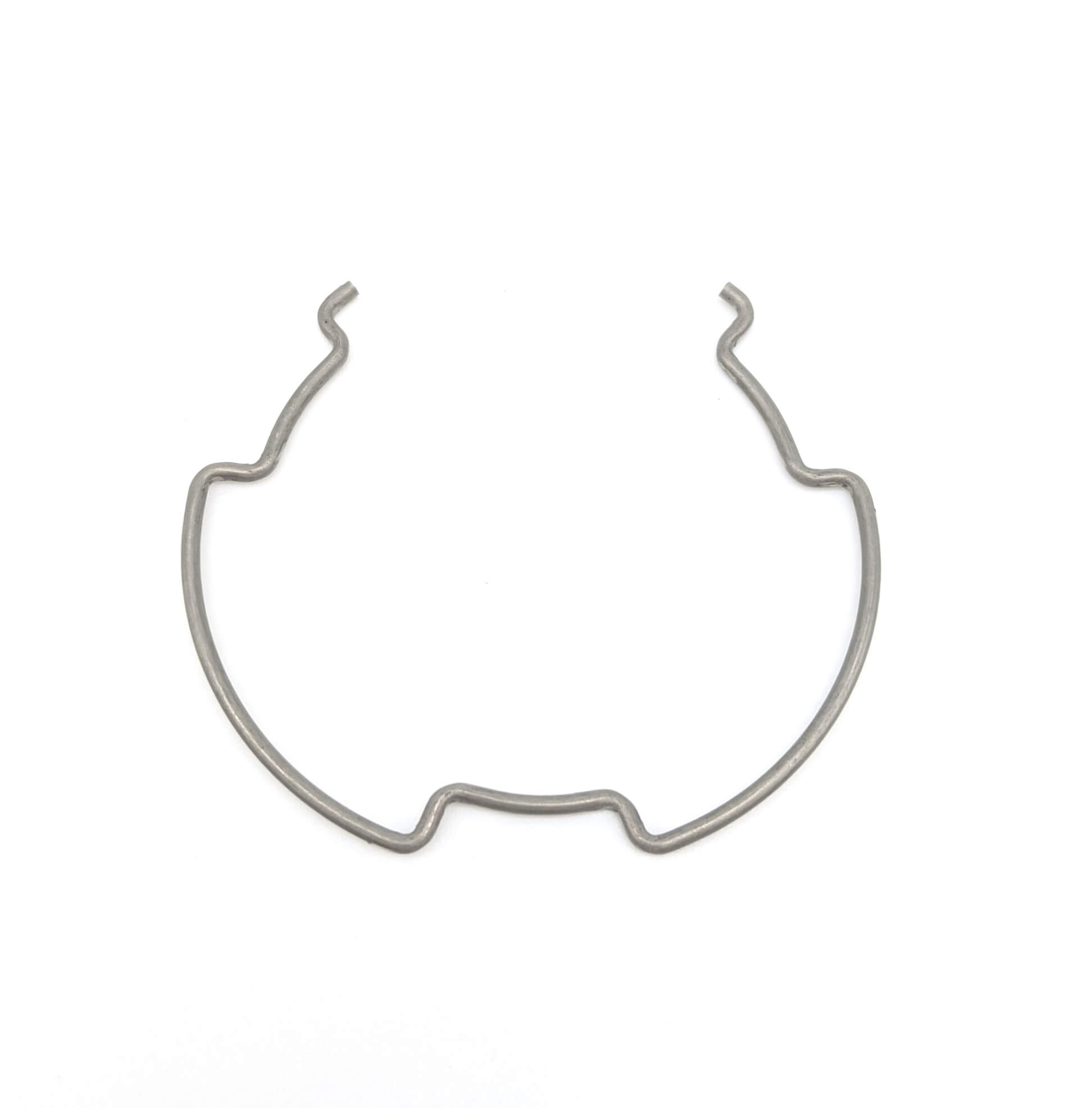

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.