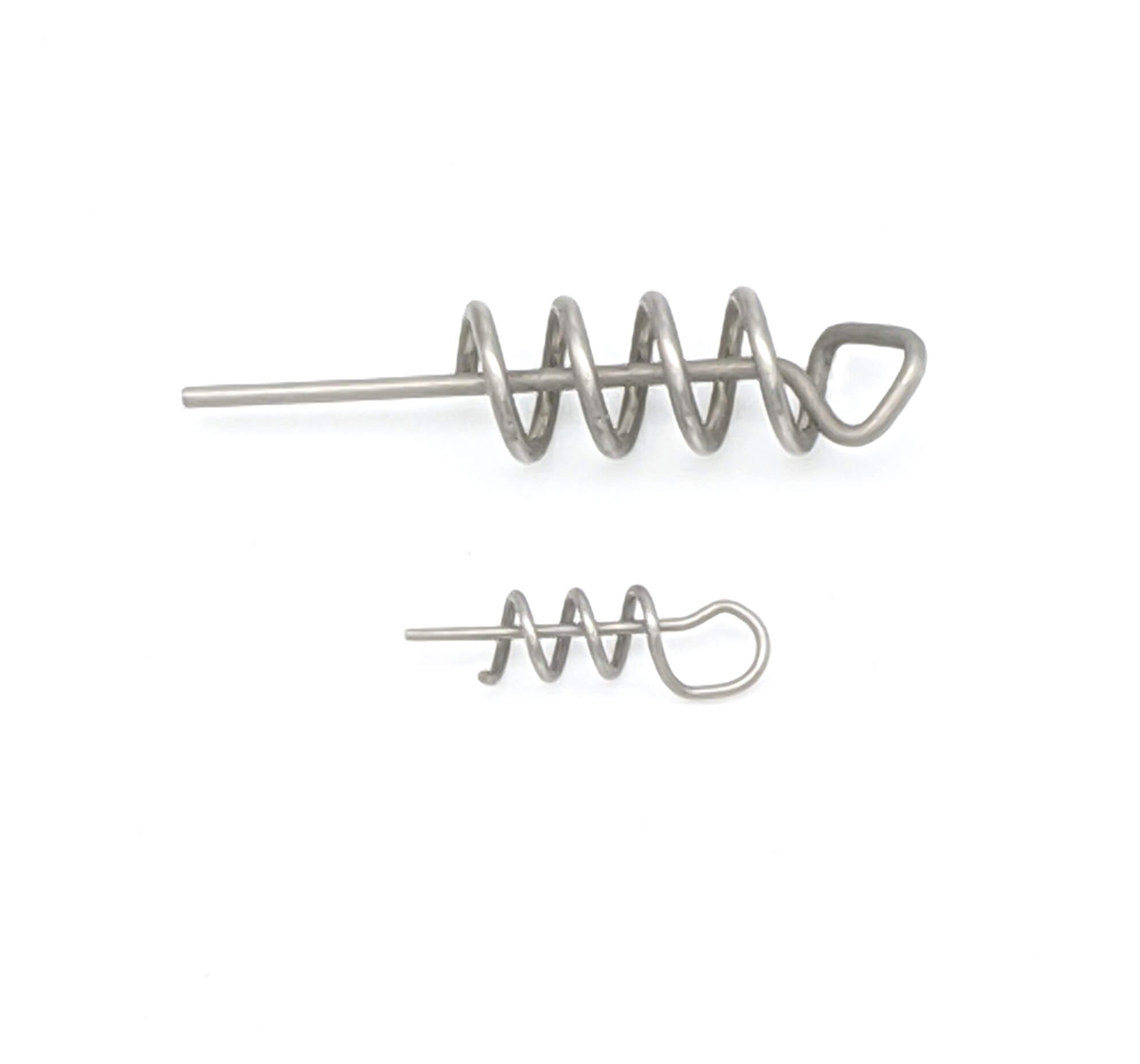

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of engineering, springs are ubiquitous components, silently working behind the scenes to provide essential functionalities in countless applications. From the delicate balance of a watch hairspring to

In the realm of engineering, springs are ubiquitous components, silently working behind the scenes to provide essential functionalities in countless applications. From the delicate balance of a watch hairspring to the robust suspension system of a car, springs play a crucial role in shaping our world. While conventional springs offer predictable force-displacement characteristics, a new breed of springs, known as variable stiffness springs, is emerging, promising unparalleled versatility and enhanced performance in a wide range of industries.

Variable stiffness springs, as their name suggests, possess the remarkable ability to dynamically adjust their stiffness, allowing them to respond to changing loads and environmental conditions with remarkable adaptability. Unlike their fixed-stiffness counterparts, these springs are not bound by a predetermined force-displacement relationship but can seamlessly morph their characteristics on demand. This revolutionary feature opens up a plethora of possibilities, enabling engineers to design systems with previously unattainable levels of precision, efficiency, and responsiveness.

The magic of variable stiffness springs lies in their ingenious design and the interplay of various physical principles. One common approach involves integrating smart materials, such as shape memory alloys or magneto-rheological fluids, into the spring's structure. These materials exhibit remarkable properties that can be manipulated by external stimuli, such as temperature or magnetic fields, resulting in a change in the spring's stiffness. Another approach involves employing mechanical mechanisms to alter the spring's configuration, thereby modifying its stiffness. These mechanisms can range from simple adjustments to intricate systems that allow for continuous variation in stiffness.

The applications of variable stiffness springs are as diverse as the industries they serve. In robotics, they can enhance the dexterity and adaptability of robotic limbs, enabling them to handle delicate tasks with precision or exert powerful forces when needed. In automotive engineering, variable stiffness suspension systems can optimize ride comfort and handling by adapting to varying road conditions. In aerospace, they can contribute to the development of more efficient and agile aircraft by adjusting the stiffness of control surfaces. In medical devices, variable stiffness implants can provide personalized support and rehabilitation by adapting to the patient's specific needs.

The potential of variable stiffness springs extends far beyond conventional applications. They are poised to revolutionize fields such as energy harvesting, where they can be used to capture and store mechanical energy more efficiently. In prosthetic devices, they can provide more natural and responsive movement, enhancing the lives of individuals with disabilities. In sports equipment, they can offer enhanced performance by adapting to the athlete's movements and providing personalized support.

While variable stiffness springs hold tremendous promise, their widespread adoption faces several challenges. The development of these springs requires advanced materials and sophisticated manufacturing processes, which can be costly and complex. Integrating these springs into existing systems may also necessitate significant design modifications and adjustments. Moreover, the long-term reliability and durability of these springs under demanding conditions require further research and development. However, the potential benefits of variable stiffness springs far outweigh the challenges, and the ongoing efforts to overcome these obstacles are paving the way for a new era of innovative design and enhanced performance across a wide spectrum of industries.

Variable stiffness springs represent a paradigm shift in spring technology, offering a remarkable opportunity to elevate design and performance across a broad range of applications. Their adaptability, responsiveness, and efficiency make them a valuable tool for engineers seeking to push the boundaries of innovation. As research and development continue to advance, variable stiffness springs are poised to become an integral part of the technological landscape, shaping the future of countless industries and enhancing the lives of people around the world. It is an exciting time to be witnessing the emergence of this revolutionary technology, and we can only anticipate the transformative innovations that lie ahead.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.