Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Engine maintenance is an essential part of keeping your vehicle running smoothly and efficiently. One crucial component in this process is the valve spring, which plays a vital role in

Engine maintenance is an essential part of keeping your vehicle running smoothly and efficiently. One crucial component in this process is the valve spring, which plays a vital role in the opening and closing of engine valves. Over time, valve springs can wear out or become damaged, requiring replacement. This is where a valve spring compression tool comes in handy. This handy tool allows you to safely and efficiently compress the valve spring, making it easier to remove and replace the old spring with a new one. In this comprehensive guide, we'll delve into the world of valve spring compression tools, exploring their types, features, and how to choose the right one for your needs.

Before we dive into the specifics of valve spring compression tools, let's understand the critical role valve springs play in your engine's performance. Valve springs are essential for controlling the timing and motion of your engine's intake and exhaust valves. They work by resisting the force of the camshaft, ensuring that the valves close tightly and prevent leakage.

Imagine a valve spring as a tiny but powerful spring holding a door shut. When the camshaft pushes the valve open, the spring's resistance allows it to open quickly and accurately. When the camshaft retracts, the spring's tension pulls the valve closed, preventing any gases from escaping. This process happens thousands of times per minute, making valve springs an integral part of your engine's smooth operation.

Valve springs are designed to withstand high pressures and repeated cycles of compression and extension. However, they can wear down over time, resulting in decreased performance or even complete failure. When a valve spring fails, it can lead to a range of issues, including engine misfires, reduced power, and potentially serious damage to your engine. To prevent these problems, you need to replace worn-out or damaged valve springs.

Replacing valve springs requires a specialized tool - the valve spring compression tool. These tools allow you to safely and effectively compress the valve spring, making it easy to remove and replace. Without a compression tool, you'd be unable to safely access the valve spring and could potentially damage the engine.

Valve spring compression tools come in various styles, each designed to suit different engine configurations and valve spring setups. Here's a breakdown of the most common types:

Choosing the right valve spring compression tool depends on your specific needs and the engine you're working on. Here are some factors to consider:

Using a valve spring compression tool is a critical task that demands careful handling. Here are some safety tips to keep in mind:

A valve spring compression tool is an essential tool for anyone serious about engine maintenance. By using this tool properly, you can safely and efficiently replace worn-out or damaged valve springs, ensuring your engine runs smoothly and reliably. Remember to choose a tool that is compatible with your engine and valve spring configuration, and always follow safety guidelines to prevent accidents.

With the right tool and a good understanding of valve spring compression, you can tackle engine maintenance with confidence and keep your vehicle running at peak performance.

Investing in a quality valve spring compression tool is a wise decision for any car enthusiast or mechanic. It not only simplifies valve spring replacement but also helps prevent potential engine damage, ensuring a smoother and more reliable ride.

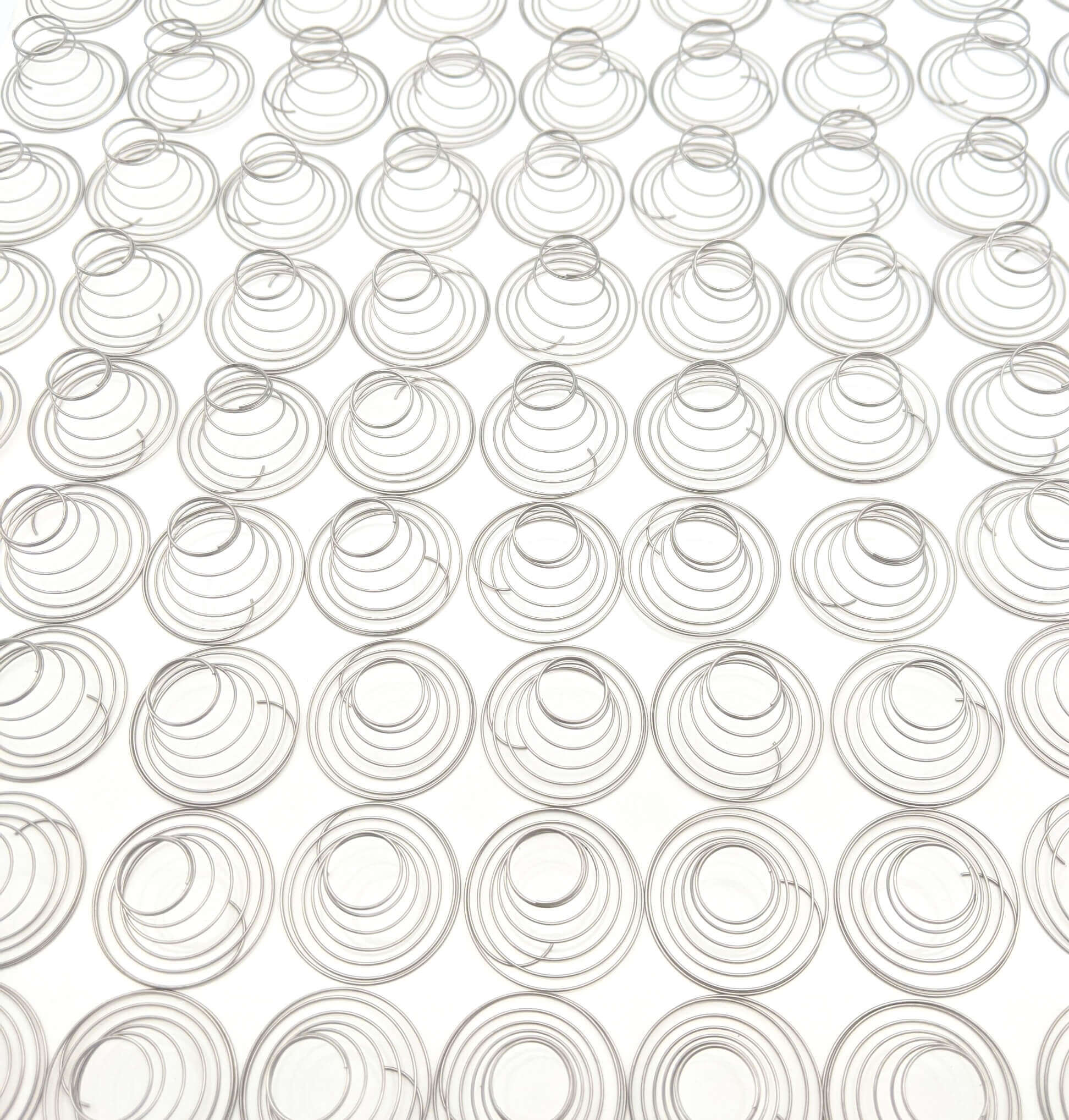

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.