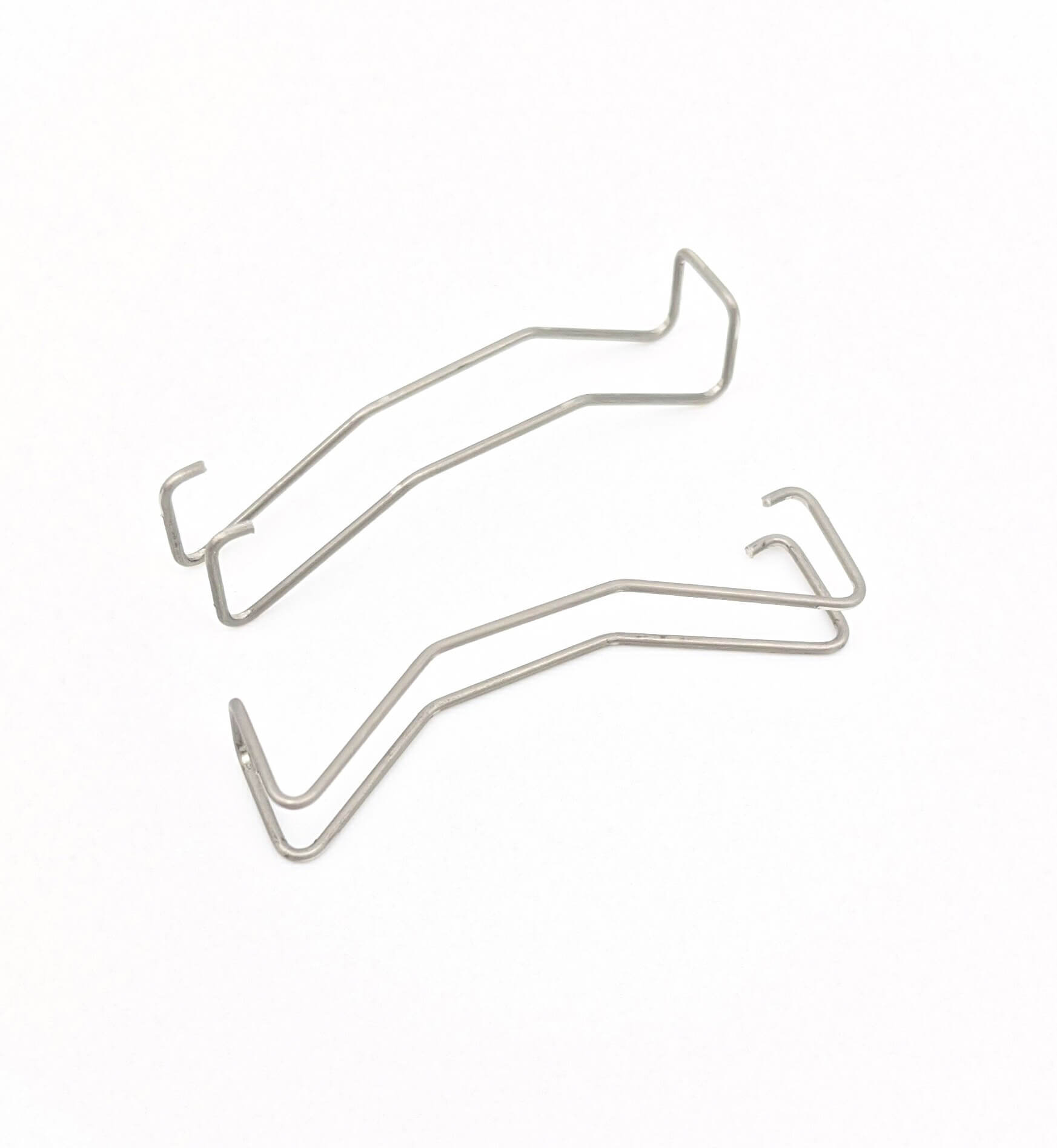

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Engine maintenance is crucial for ensuring optimal performance and longevity, and valve spring compression is a fundamental part of this process. Whether you're a seasoned mechanic or a DIY enthusiast,

Engine maintenance is crucial for ensuring optimal performance and longevity, and valve spring compression is a fundamental part of this process. Whether you're a seasoned mechanic or a DIY enthusiast, having the right tools can make all the difference. A valve spring compression tool is a specialized tool designed to safely and effectively compress valve springs, allowing for the removal and replacement of valve seals, valve guides, and other components. This guide delves into the world of valve spring compression tools, exploring their importance, different types, and how to choose the right one for your needs.

Valve springs play a vital role in the smooth operation of your engine. They are responsible for keeping the valves closed during the compression and power strokes, ensuring efficient combustion and performance. However, over time, these springs can wear out, lose their tension, or become damaged, leading to a host of engine problems.

Valve spring compression is a necessary procedure when you need to access or replace components within the valve train. This includes tasks such as:

Without a proper valve spring compression tool, attempting these tasks can be incredibly dangerous. The springs are under significant pressure, and any mishandling can result in serious injury or even death. That's where a valve spring compression tool comes in, providing a safe and controlled way to manage the tension of these critical components.

Valve spring compression tools come in a variety of designs, each with its own advantages and disadvantages. Here's a breakdown of some of the most common types:

These tools utilize a mechanism that compresses the spring from the outside. They are generally easier to use and less expensive than internal tools. However, they can sometimes be bulky and may not be suitable for all applications. Common types include:

These tools are inserted into the cylinder head to compress the spring from the inside. They offer a more precise and controlled compression process, especially in tight spaces. However, they can be more complex to use and typically require more specialized knowledge. Some examples include:

When choosing a valve spring compression tool, consider these key factors:

Using a valve spring compression tool safely and effectively requires proper technique. Here are a few tips:

A valve spring compression tool is a valuable asset for any DIY enthusiast or professional mechanic who performs engine work. It ensures safety and control during the compression process, allowing for efficient removal and replacement of valve components. When choosing a tool, consider compatibility, ease of use, durability, and cost. By following the tips provided, you can use a valve spring compression tool safely and effectively, keeping your engine running smoothly and efficiently for years to come.

Investing in a quality valve spring compression tool is a wise decision for anyone who wants to take control of their engine maintenance. It empowers you to tackle critical tasks like valve seal replacement, valve guide removal, and valve spring inspection with confidence and safety. Remember to always prioritize safety, use the right tool for the job, and follow the manufacturer's instructions to ensure a successful and enjoyable experience.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.