Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

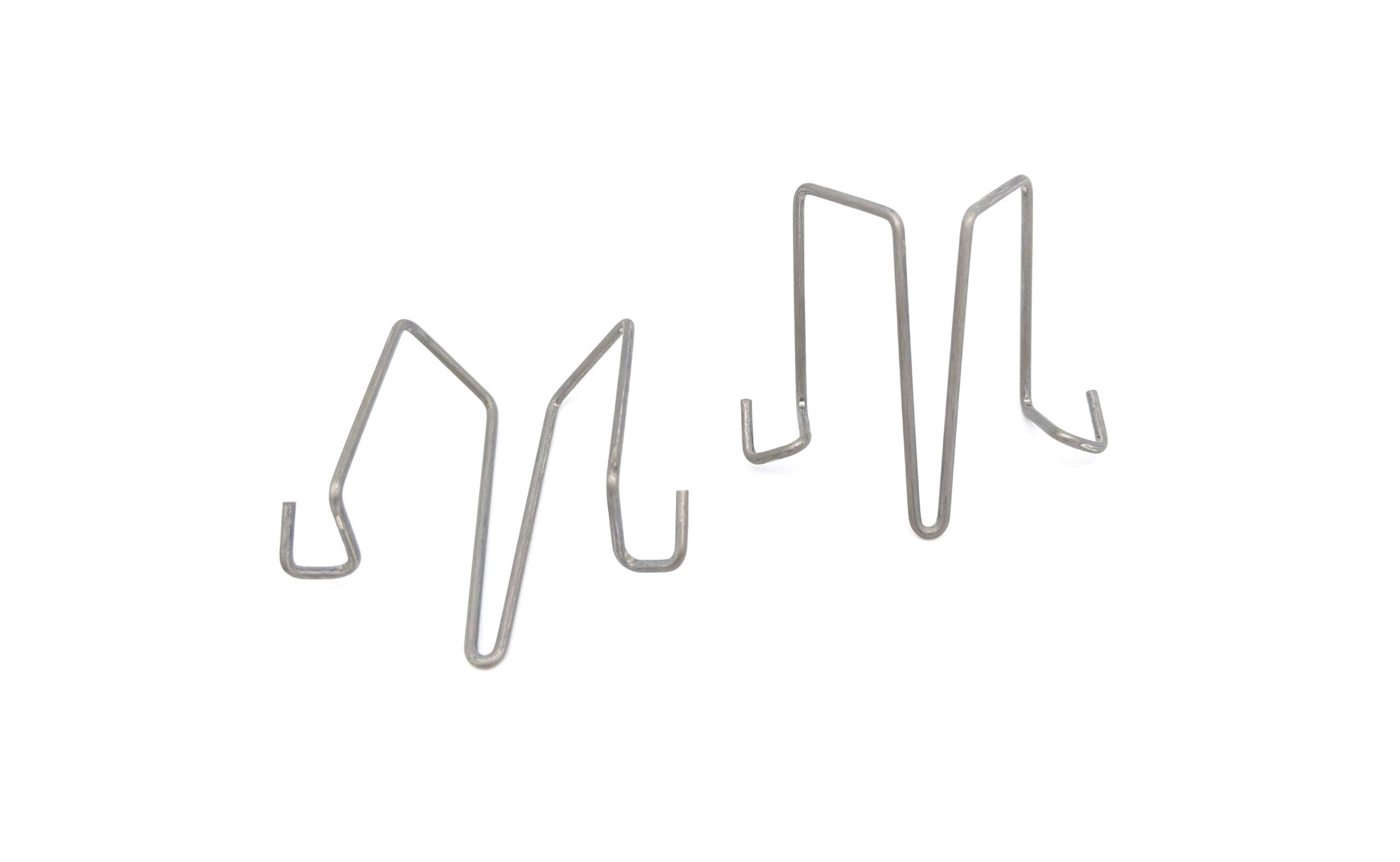

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous and versatile devices, are essential components in countless machines and structures. Their ability to store and release energy, providing elasticity and resilience, makes them indispensable for various

Springs, those ubiquitous and versatile devices, are essential components in countless machines and structures. Their ability to store and release energy, providing elasticity and resilience, makes them indispensable for various applications. Among the many types of springs, compression springs are particularly prevalent, used in everything from automotive suspensions to delicate electronic components. Understanding the maximum compression of a compression spring is paramount for engineers and designers, ensuring safe and efficient operation. This article delves into the intricacies of maximum spring compression, exploring the factors that govern it and presenting the fundamental formula that governs this critical parameter.

A compression spring, as the name suggests, is designed to absorb energy by shortening its length when subjected to an axial force. As a force is applied to the spring, the coils come closer together, storing potential energy within the spring's material. This compressed state is temporary; when the applied force is removed, the spring expands back to its original length, releasing the stored energy. The maximum compression of a spring refers to the maximum amount of shortening it can withstand before experiencing permanent deformation or failure.

The maximum compression a spring can endure is determined by several factors, each playing a critical role in the spring's performance and longevity:

The maximum compression of a compression spring can be calculated using a fundamental formula that takes into account the spring's physical properties and the material's limitations. The formula is as follows:

Maximum Compression (Cmax) = (Free Length (L0) - Solid Length (Ls)) / (Number of Active Coils (N) * Spring Index (C))

It is crucial to note that this formula is a theoretical calculation and should be used in conjunction with safety factors to account for real-world variables and potential uncertainties. Factors like material fatigue, manufacturing tolerances, and environmental conditions can all impact the actual maximum compression a spring can withstand.

Designing with springs requires a thorough understanding of their limitations and ensuring safe operating conditions. Here are some key considerations for spring design:

The maximum compression formula is indispensable for various engineering and design applications. It helps engineers to:

Understanding the maximum compression of a compression spring is critical for engineers and designers working with these ubiquitous components. The maximum compression formula, coupled with safety factors and a thorough understanding of material properties and design principles, enables the creation of reliable and efficient spring-based systems. By applying these concepts, designers can ensure that their spring applications function safely and effectively, contributing to the success of countless mechanical and structural systems.

The world of springs is intricate and fascinating, offering a wide array of solutions for diverse engineering challenges. Understanding the maximum compression of a spring is a fundamental aspect of spring design, ensuring both functionality and safety. By mastering this crucial concept, engineers can confidently leverage the power of springs in various applications, driving innovation and advancement across countless industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.