Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered what happens when you drop a heavy stone onto a spring? It's a simple yet intriguing scenario that highlights the interplay between gravity, mass, and the

Have you ever wondered what happens when you drop a heavy stone onto a spring? It's a simple yet intriguing scenario that highlights the interplay between gravity, mass, and the elastic properties of a spring. In this article, we'll delve into the mechanics of this phenomenon, exploring how the stone's weight, the spring's stiffness, and other factors influence the distance the spring compresses. We'll also touch upon real-world applications where understanding this principle proves crucial.

The compression of a spring is governed by Hooke's Law, a fundamental principle in physics that states the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you stretch or compress a spring, the stronger the force it exerts back. This force, known as the spring force, is what resists the stone's downward motion.

When a stone is dropped onto a spring, its potential energy due to gravity is transformed into kinetic energy as it falls. This kinetic energy is then transferred to the spring, causing it to compress. The compression distance, or how far the spring gets squeezed, depends on several factors:

The relationship between the stone's mass, the spring's stiffness, and the compression distance can be mathematically expressed as follows:

Compression Distance = (Stone's Mass * Gravity * Initial Spring Length) / (Spring Constant * 2)

Where:

This formula reveals a direct relationship between the stone's mass and the compression distance, while an inverse relationship exists between the spring's stiffness and the compression distance.

Understanding the compression of a spring by a stone is not just a theoretical concept; it has numerous practical applications in various fields:

Beyond these examples, spring compression finds applications in areas such as construction, aerospace engineering, and medical devices.

While the above discussion provides a foundational understanding of spring compression, several other factors can influence the outcome. These include:

These factors illustrate that the actual compression distance can deviate from the simple theoretical calculation, especially in real-world scenarios. It is essential to consider these additional factors for accurate analysis and design.

The compression of a spring by a stone is a fascinating demonstration of basic physics principles. While the compression distance is primarily determined by the stone's weight, the spring's stiffness, and the initial length of the spring, other factors can influence the outcome. Understanding these concepts has a wide range of practical applications in various industries, emphasizing the importance of studying this seemingly simple phenomenon.

As we delve deeper into the mechanics of spring compression, we uncover the intricate interplay of forces and energy transfer. From the simple act of dropping a stone onto a spring to the complex engineering behind shock absorbers and measurement devices, this principle has a profound impact on our world. Next time you see a spring, take a moment to appreciate the hidden forces at play, and the remarkable power of this seemingly simple object.

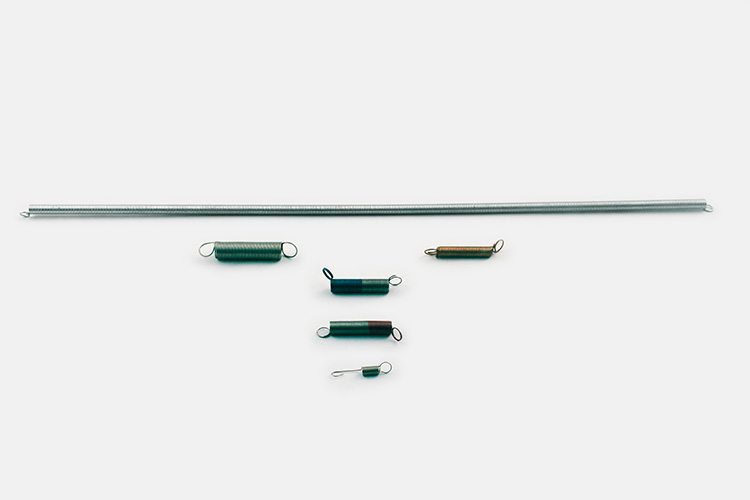

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.