Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those seemingly simple coiled devices, play a crucial role in countless mechanical systems, from the delicate workings of a watch to the robust suspension of a car. At the

Springs, those seemingly simple coiled devices, play a crucial role in countless mechanical systems, from the delicate workings of a watch to the robust suspension of a car. At the heart of their functionality lies the principle of spring compression, a fascinating phenomenon that governs their ability to store and release energy. This article delves into the intricacies of spring compression, exploring its underlying physics, the factors influencing its behavior, and its wide range of applications in various fields.

Imagine a spring, that ubiquitous coil of metal, sitting relaxed and unstretched. Now, apply a force to one end of the spring, compressing it. As you push, the spring resists, pushing back with an equal and opposite force. This resistance is governed by Hooke's Law, a fundamental principle in physics that describes the relationship between the force applied and the resulting deformation of an elastic object.

Hooke's Law states that the force (F) required to compress or extend a spring is directly proportional to the displacement (x) from its equilibrium position. The constant of proportionality is known as the spring constant (k), which represents the stiffness of the spring. Mathematically, this relationship can be expressed as F = -kx, where the negative sign indicates that the force exerted by the spring is in the opposite direction to the displacement.

The spring constant, k, is a crucial parameter that dictates how much force is needed to compress the spring by a certain amount. A higher spring constant indicates a stiffer spring, requiring more force for compression, while a lower spring constant denotes a softer spring, easily compressed with less force. The choice of spring constant is critical in designing systems where specific compression characteristics are needed.

Several factors come into play when considering the compression of a spring. Let's explore these factors in detail:

1. **Spring Material:** The material from which the spring is made significantly influences its compression behavior. Different materials exhibit varying levels of elasticity and strength. Steel springs, for instance, are known for their high strength and resilience, making them suitable for demanding applications. On the other hand, lighter materials like copper or brass are often used in applications where weight is a major consideration.

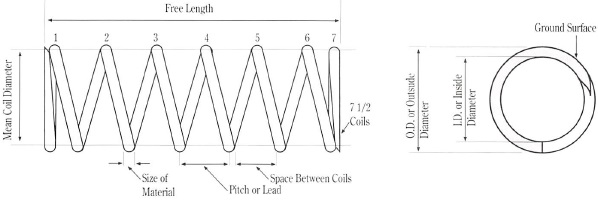

2. **Spring Geometry:** The shape and dimensions of the spring also play a crucial role in its compression characteristics. The coil diameter, wire diameter, and number of coils all contribute to the spring's stiffness. A larger coil diameter generally leads to a softer spring, while a smaller wire diameter results in a stiffer spring. The number of coils directly affects the spring's length and, consequently, its compression behavior.

3. **Spring Preload:** Preloading a spring involves applying an initial force to compress it before it is put into service. This preload can be beneficial in various ways. It can help to ensure that the spring is always in contact with the object it is meant to interact with, preventing rattling or unwanted movements. Preload can also be used to fine-tune the spring's operating range and ensure that it operates within its elastic limit.

4. **Temperature:** Temperature fluctuations can impact the behavior of spring compression. As temperature rises, materials tend to expand, which can affect the spring's stiffness. Conversely, lower temperatures can cause materials to contract, potentially making the spring stiffer. Understanding the thermal properties of the spring material is essential for designing systems that can function reliably over a wide range of temperatures.

5. **Fatigue:** Repeated compression and extension of a spring can lead to fatigue, a gradual weakening of the spring material over time. Fatigue is a complex phenomenon that depends on factors like the load amplitude, frequency of loading, and the material's inherent fatigue resistance. Understanding and mitigating fatigue is crucial for ensuring the longevity and reliability of spring-based systems.

Spring compression finds applications across a vast array of industries and technologies, making it an indispensable element in modern engineering. Let's explore some notable examples:

1. **Automotive Industry:** Spring compression is fundamental to the suspension systems of vehicles. Suspension springs absorb shocks and vibrations, providing a smooth ride for passengers and protecting the vehicle from damage. These springs also contribute to the vehicle's handling and stability, ensuring safe and comfortable driving.

2. **Mechanical Devices:** Spring compression is essential for countless mechanical devices, from simple door closers and spring-loaded clamps to more complex mechanisms in machines and equipment. These springs provide the necessary force to return components to their original positions or to activate specific functions.

3. **Electronics and Appliances:** Spring compression is also widely used in electronic devices and appliances. From the tiny springs in mechanical switches to the larger springs that support the internal components of televisions and refrigerators, springs ensure proper functionality and prevent damage.

4. **Aerospace and Defense:** Spring compression is employed in a wide range of applications in aerospace and defense industries, from the intricate mechanisms of aircraft control systems to the suspension systems of military vehicles. These springs must be able to withstand extreme temperatures, vibrations, and loads, making them crucial for ensuring the safety and performance of these systems.

5. **Medical Devices:** Spring compression plays a vital role in medical devices, from the delicate springs in surgical instruments to the more robust springs used in prosthetic limbs and medical equipment. These springs ensure precision, control, and durability in applications where reliability and safety are paramount.

Spring compression is a fundamental principle in physics that drives the operation of countless mechanical systems. Understanding the factors influencing spring compression, such as material, geometry, preload, temperature, and fatigue, is crucial for designing and implementing reliable and efficient spring-based systems. From the automotive industry to medical devices, the applications of spring compression are vast and continue to expand as technology advances. Whether it's a simple door closer or a complex aircraft component, the humble spring, through its ability to store and release energy, remains an indispensable element of modern engineering and technology.

As we delve deeper into the world of spring compression, we gain a deeper appreciation for the seemingly simple yet profound role these coiled devices play in our lives. From the everyday convenience of a car's suspension to the intricate workings of medical equipment, spring compression continues to shape our world, driving innovation and ensuring the functionality of countless mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.