Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

A humble tension spring, often overlooked in the grand scheme of mechanical engineering, is an unassuming yet powerful component that plays a vital role in countless applications. From the delicate

A humble tension spring, often overlooked in the grand scheme of mechanical engineering, is an unassuming yet powerful component that plays a vital role in countless applications. From the delicate workings of a watch to the robust machinery of heavy industries, these seemingly simple coiled wires hold the key to smooth operation, precise movement, and consistent performance. This article delves into the heart of tension springs, exploring their fundamental principles, diverse applications, and the crucial factors that determine their effectiveness.

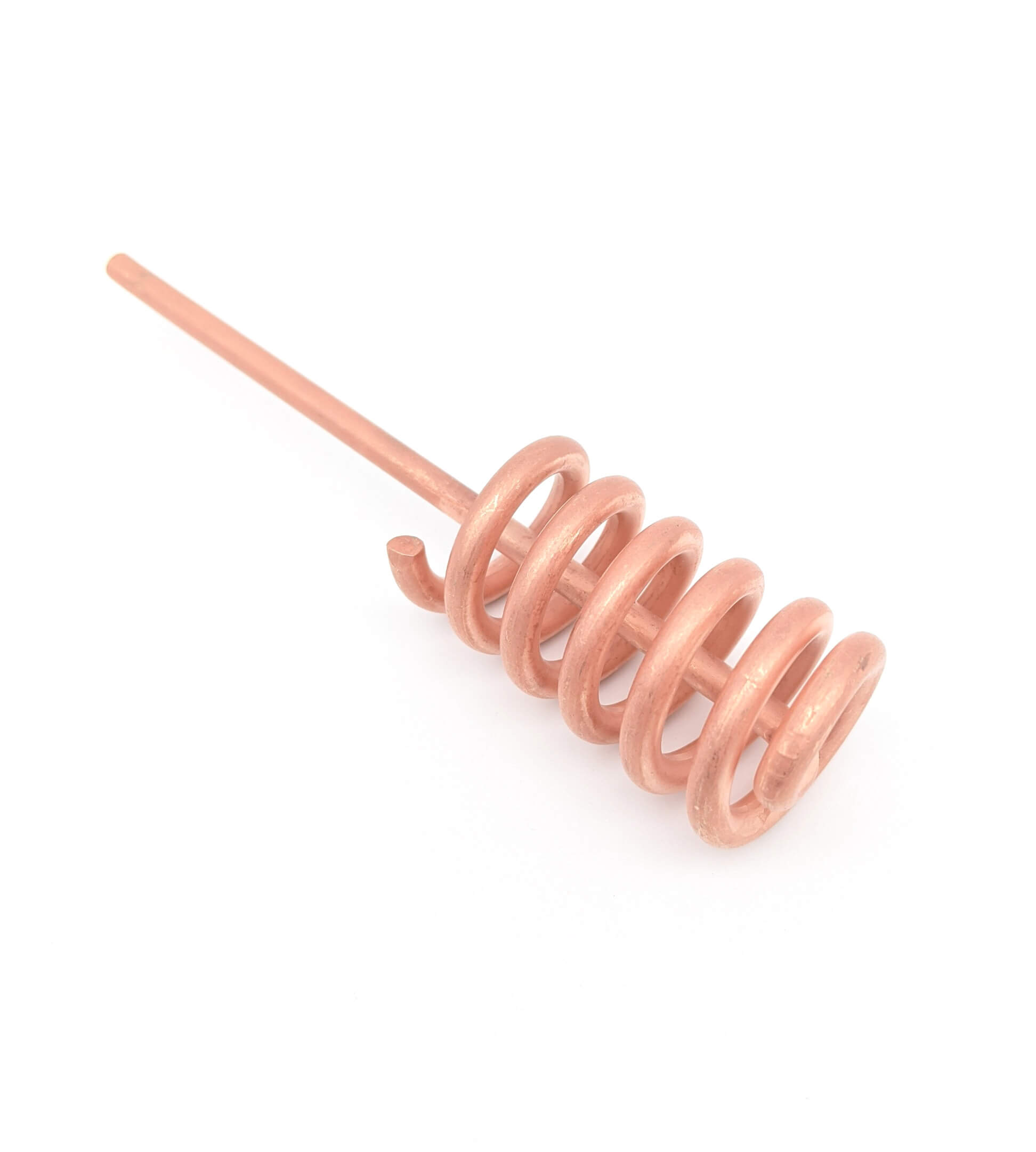

At its core, a tension spring is a coiled wire designed to store potential energy when stretched and release it upon contraction. Unlike compression springs, which resist compressive forces, tension springs are engineered to withstand tensile forces, effectively acting as a springy tether. This ability to store and release energy makes them indispensable in numerous mechanical systems, allowing for controlled movement, precise positioning, and reliable performance.

The spring's behavior is dictated by its inherent properties: the material used, the wire diameter, the number of coils, and the spring's overall length. These factors, intricately woven together, define the spring's stiffness, known as its spring constant, which quantifies the force required to stretch it a specific distance. A higher spring constant indicates a stiffer spring, requiring greater force to stretch, while a lower constant reflects a more flexible spring. This interplay between material properties and geometric design allows engineers to tailor tension springs for specific applications, achieving the desired level of force and displacement.

Tension springs, with their remarkable ability to store and release energy, find themselves woven into the fabric of diverse industries, proving their versatility in a multitude of applications.

In the realm of consumer products, tension springs silently orchestrate the smooth functioning of everyday items. They provide the springy action in retractable pens, ensuring a controlled ink flow. They are responsible for the reliable recoil of tape measures, allowing for quick and accurate measurements. And in the world of electronics, they play a crucial role in the operation of switches and buttons, providing a tactile feedback mechanism.

The automotive industry relies heavily on tension springs for critical functions. They contribute to the smooth operation of door latches, ensuring a secure and reliable closure. They help to keep the hood securely in place, preventing accidental opening during driving. And they are integral components of the suspension system, contributing to a comfortable and safe ride.

Beyond consumer goods and automotive applications, tension springs play a vital role in heavy industries. In construction, they are employed in lifting mechanisms, contributing to the smooth operation of cranes and hoists. In manufacturing, they are essential components of conveyor belts, ensuring a steady and efficient flow of materials. And in the realm of aerospace engineering, they are used in landing gear mechanisms, contributing to a safe and controlled landing.

Selecting the right tension spring for a specific application requires careful consideration of several crucial factors.

The primary factor is the **force requirement**, which dictates the spring's stiffness and ability to handle the desired load. A thorough understanding of the forces involved is crucial to ensure the spring can perform its function effectively without exceeding its capacity.

The **space available** is another critical consideration. Tension springs come in various sizes and configurations, and selecting a spring that fits within the available space is essential. The **material of the spring** is crucial, as it affects its strength, durability, and resistance to corrosion. For applications demanding high strength and resistance to wear, materials like stainless steel are often preferred. For applications requiring corrosion resistance, materials like nickel-plated steel or phosphor bronze are suitable choices.

Lastly, the **operating environment** plays a significant role. Factors like temperature extremes, humidity, and exposure to corrosive substances can influence the choice of material and the overall design of the spring. For applications operating in harsh environments, special considerations must be made to ensure the spring's longevity and performance.

Tension springs, though often overlooked, are integral components in countless applications. Their ability to store and release energy, their versatility across diverse industries, and their crucial role in ensuring smooth operation make them unsung heroes of mechanical engineering.

As we continue to explore the intricate world of mechanics, understanding the functionality and applications of these simple yet powerful components becomes increasingly important. By recognizing the vital role of tension springs, we gain a deeper appreciation for the ingenuity and precision that drive the world of mechanical engineering.

The seemingly simple tension spring is a testament to the power of effective design. It is a reminder that even the smallest components can play a significant role in the smooth operation of complex systems. As we delve deeper into the world of engineering, it is important to remember the contributions of these unassuming yet vital elements. With a deeper understanding of tension springs, we can better appreciate the intricate workings of the machines that shape our world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.