Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

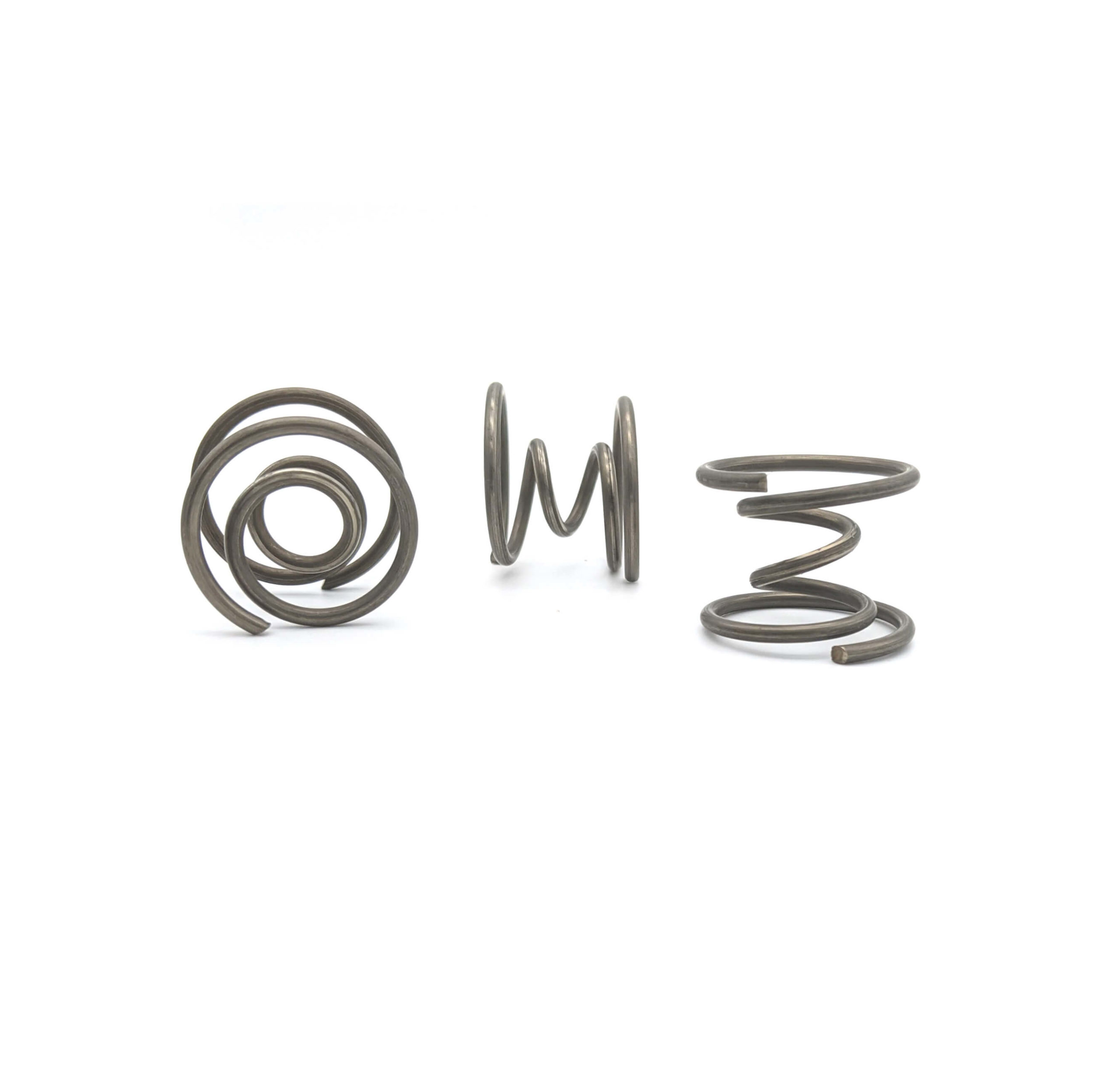

Spira wave springs, also known as helical wave springs, represent a fascinating and increasingly popular type of spring design. They offer a unique blend of high force output, compact size,

Spira wave springs, also known as helical wave springs, represent a fascinating and increasingly popular type of spring design. They offer a unique blend of high force output, compact size, and durability, making them suitable for a wide range of applications. This article will delve into the intricacies of spira wave spring design, explore their diverse applications, and highlight the compelling benefits they bring to various industries.

Spira wave springs, unlike conventional coil springs, derive their force from the bending and unbending of their wave-like structure. This design allows them to achieve incredibly high force outputs in a remarkably compact footprint. The wave configuration also contributes to their high fatigue resistance, making them ideal for applications requiring extended service life. This type of spring is typically made from various materials, including stainless steel, nickel alloys, and other high-performance materials, depending on the specific application and environmental conditions.

The unique functionality of spira wave springs stems from their inherent design. Each wave within the spring acts as an individual cantilever beam, absorbing energy when compressed and releasing it upon expansion. The spring's force characteristics are highly dependent on the number of waves, the material's stiffness, and the overall geometry of the spring. This intricate interplay allows for precise control over the spring's force output, making it highly adaptable to various applications.

The versatility of spira wave springs shines through in their broad range of applications. They find their niche in industries as diverse as automotive, aerospace, electronics, medical devices, and industrial machinery. Here are some notable examples:

The adoption of spira wave springs is driven by the compelling advantages they offer. Here are some key benefits:

Spira wave springs represent a testament to innovative engineering design, pushing the boundaries of spring technology. Their unique combination of high force output, compact size, durability, and versatility makes them an invaluable component in various industries. As technology continues to advance, we can expect further refinements and innovations in spira wave spring design, unlocking even greater potential for this remarkable spring type.

In conclusion, spira wave springs offer a compelling alternative to traditional coil springs, providing a unique blend of performance, efficiency, and durability. Their diverse applications, ranging from automotive and aerospace to electronics and medical devices, underscore their importance in various industries. As research and development in spring technology continues, we can anticipate even more innovative applications and benefits from spira wave springs, further solidifying their position as a key player in the future of spring design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.