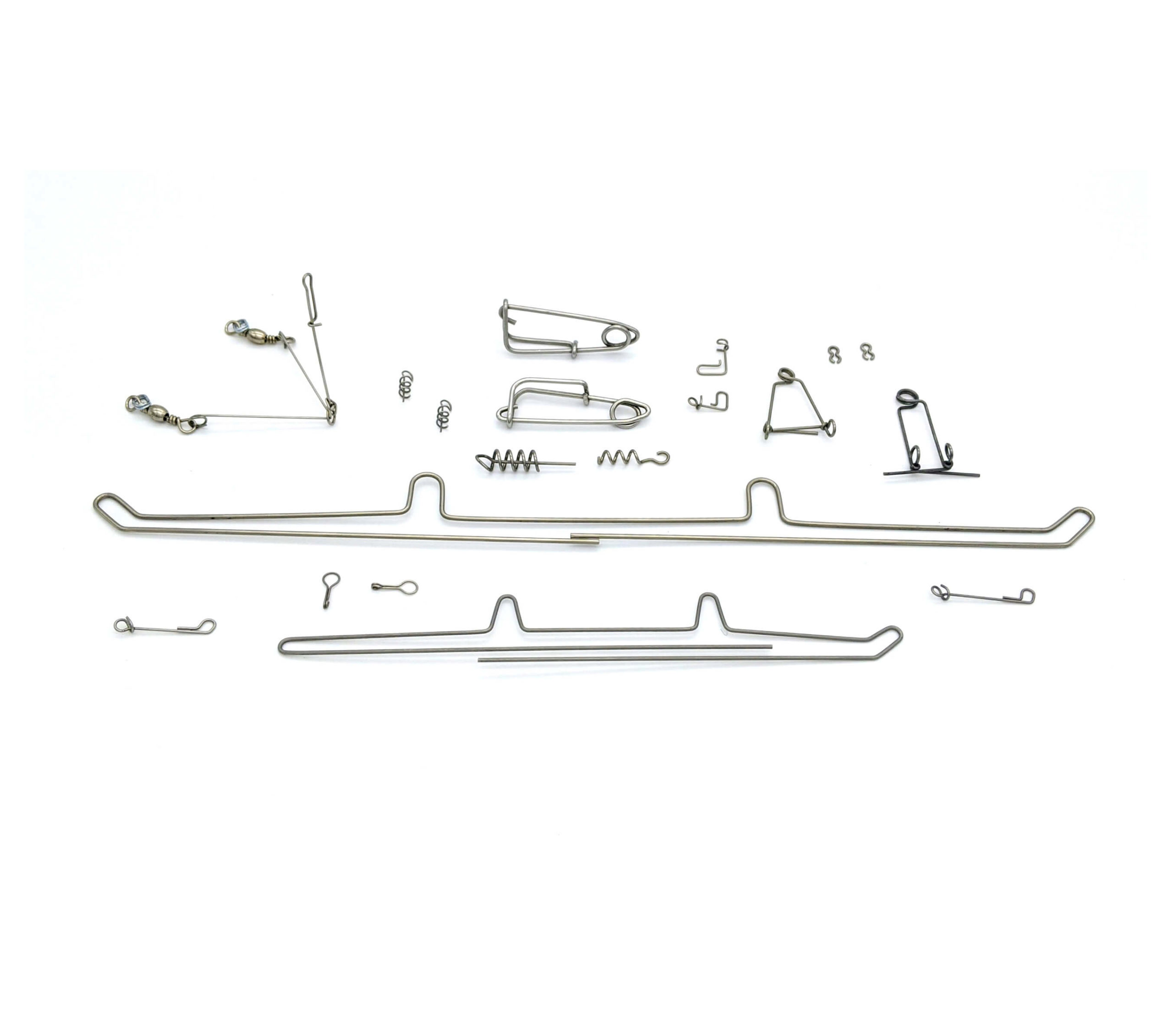

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs are everywhere, quietly powering countless mechanisms we rely on daily. But have you ever wondered how engineers determine the perfect spring for a specific application? That's where torsion

Before we can truly appreciate torsion spring charts, we need to understand the fundamental nature of these mechanical marvels. Unlike their extension or compression counterparts, torsion springs store and release energy when twisted along their axis. Picture a tightly wound clock spring; that's a prime example of a torsion spring in action. They're often found in clothespins, garage doors, and even hinges, demonstrating their remarkable versatility.

So, what makes these springs tick? It all boils down to torque, the twisting force that drives their operation. Torque is directly proportional to the angle through which the spring is twisted, a relationship neatly captured by Hooke's Law. In simpler terms, the more you twist a torsion spring, the greater the torque it exerts.

Now, imagine you're an engineer tasked with selecting a torsion spring for a new design. You're faced with a sea of options, each with unique properties. How do you navigate this complex landscape? Enter the torsion spring chart, your trusty guide. These charts provide a visual representation of a spring's key characteristics, allowing for quick and informed decision-making. Let's break down the essential elements typically found in a torsion spring chart:

This refers to the thickness of the wire used to form the spring, directly impacting its strength and flexibility. Thicker wires generally translate to stronger springs but can limit the maximum deflection.

This represents the average diameter of the spring coils. It plays a crucial role in determining the spring's torque output and overall size.

This denotes the number of complete turns in the spring. More coils generally result in a greater angular deflection but may increase the spring's overall length.

This refers to the straight sections extending from the spring's body. They serve as mounting points, determining how the spring interacts with other components.

This is the twisting force exerted by the spring. It's typically presented as a graph, showcasing the relationship between torque and angular deflection. You might see this labeled as "moment" as well, which is just another term for torque.

This indicates how much torque changes for a given angular deflection. It reflects the spring's stiffness, with higher rates indicating a stiffer spring.

Let's bring these concepts to life with a practical example. Imagine you're designing a safety latch for a heavy-duty toolbox. You need a torsion spring to provide the necessary force to securely lock the lid. Armed with a torsion spring chart, you can carefully evaluate the available options:

- First, determine the desired torque needed to keep the toolbox securely closed. This might involve calculations based on the lid's weight and the desired latching force.

- Next, refer to the chart's torque-deflection curves. Look for springs that provide the target torque within the anticipated angular deflection of the latch mechanism.

- Pay attention to the wire diameter. You'll need a spring strong enough to handle the load but not so thick that it hinders smooth operation.

- Consider the spring's overall dimensions, ensuring it fits within the allocated space in your design.

By systematically analyzing the chart's information, you can pinpoint the ideal torsion spring that meets all your design criteria. You'll have confidence knowing the selected spring will provide the necessary force, smoothly operate within the intended range of motion, and fit seamlessly within your design's spatial constraints.

The beauty of torsion spring charts lies in their ability to distill complex engineering data into a readily digestible format. Instead of grappling with pages of equations, engineers can quickly assess various spring characteristics and make informed choices. These charts act as a visual bridge, connecting theoretical principles with practical applications. They empower engineers to select springs with precision, ensuring optimal performance and longevity in their designs.

While torsion spring charts are invaluable for choosing the right spring, their utility extends beyond mere selection. They offer a window into the nuanced behavior of these mechanical wonders. By analyzing the torque-deflection curves, engineers can gain insights into factors like hysteresis, the energy loss during loading and unloading cycles. They can also assess the spring's fatigue life, predicting its long-term performance under repeated stress.

In essence, torsion spring charts serve as indispensable tools in the arsenal of any engineer working with these versatile components. They provide a visual roadmap, guiding engineers through the selection process, and unlocking deeper insights into the behavior of torsion springs. By mastering the language of these charts, engineers can harness the power of these mechanical marvels, creating innovative and reliable designs that power our world.

As we've explored, torsion spring charts aren't just static diagrams; they're dynamic tools that breathe life into engineering designs. By understanding their language, we can unlock a world of possibilities, creating mechanisms that are both functional and elegant. So, the next time you encounter a torsion spring, take a moment to appreciate the intricate dance of forces at play, guided by the silent wisdom of the torsion spring chart.Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.