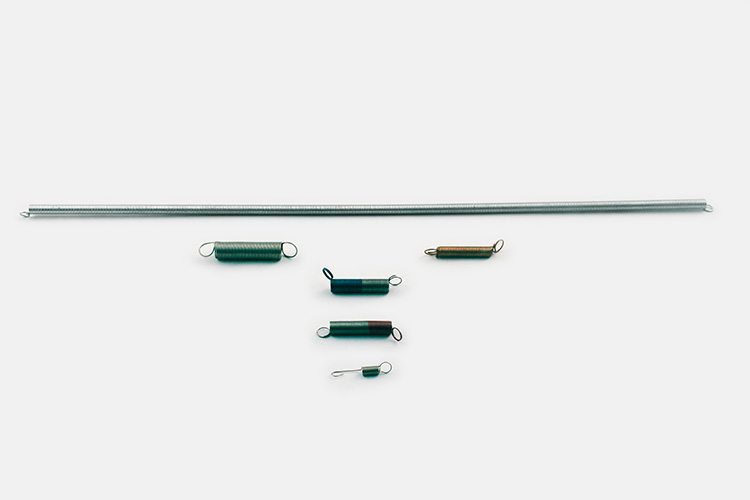

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

The world of springs is full of fascinating intricacies, particularly when it comes to understanding their compression behavior. The spring compression formula, a cornerstone of mechanical engineering, allows us to

The world of springs is full of fascinating intricacies, particularly when it comes to understanding their compression behavior. The spring compression formula, a cornerstone of mechanical engineering, allows us to predict and control how much a spring will compress under a given load. It's a powerful tool used in countless applications, from designing intricate clockwork mechanisms to crafting robust vehicle suspensions. In this comprehensive guide, we'll delve into the heart of the spring compression formula, exploring its derivation, applications, and the crucial factors that influence its accuracy.

At its core, the spring compression formula embodies Hooke's Law, a fundamental principle in physics. This law states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you compress a spring, the greater the force it pushes back with.

The spring compression formula is mathematically represented as:

F = kx

Where:

• F is the force applied to the spring (measured in Newtons or pounds)

• k is the spring constant (measured in Newtons per meter or pounds per inch)

• x is the displacement or compression of the spring (measured in meters or inches)

The spring constant (k) is a measure of a spring's stiffness. A higher spring constant indicates a stiffer spring, requiring more force to compress it. Imagine a sturdy coil spring in a car suspension versus a delicate spring in a watch – the car spring would have a much higher spring constant.

The spring constant (k) plays a pivotal role in the spring compression formula, acting as a bridge between the applied force and the resulting compression. It's a fundamental characteristic of a spring, often determined through experimentation or using specific formulas that account for the spring's geometry and material properties.

For a helical coil spring, the spring constant can be calculated using the following formula:

k = (Gd^4)/(8D^3n)

Where:

• G is the shear modulus of the spring material (often steel)

• d is the wire diameter of the spring

• D is the mean coil diameter of the spring

• n is the number of active coils in the spring

The spring compression formula finds its way into countless engineering applications, impacting our daily lives in subtle and profound ways. Here are some examples:

• **Vehicle Suspensions:** Springs are the backbone of vehicle suspensions, absorbing shocks and ensuring a smooth ride. The spring compression formula helps engineers design springs with the right stiffness to handle the weight of the vehicle and provide optimal ride comfort.

• **Mechanical Clocks:** The intricate movements of clocks rely on springs to store and release energy. The spring compression formula ensures that the springs provide the right amount of force to power the gears and maintain accurate timekeeping.

• **Medical Devices:** Springs are used in medical devices like surgical instruments and prosthetic limbs. The formula helps ensure these devices operate with the appropriate force and flexibility, enabling delicate surgical procedures and providing functional support.

• **Industrial Equipment:** Springs are essential in countless industrial applications, from clamping machinery to operating pneumatic systems. The spring compression formula ensures that springs provide the necessary force and stability for these applications.

The spring compression formula is a powerful tool, but its accuracy relies on several factors:

• **Spring Material:** The choice of spring material significantly influences its stiffness and compression characteristics. Steel is a common choice for springs, offering good strength and resilience. Other materials, like phosphor bronze or titanium, might be selected for specific applications requiring corrosion resistance or other properties.

• **Spring Geometry:** The spring's geometry, including its wire diameter, mean coil diameter, and number of coils, plays a crucial role in its spring constant and compression behavior. The formula accurately reflects these geometric relationships.

• **Spring Load:** The force applied to the spring (its load) directly influences its compression. Heavier loads will compress the spring more than lighter loads, as predicted by the formula.

• **Spring Temperature:** Temperature can influence a spring's stiffness and compression characteristics. For most springs, a rise in temperature will slightly reduce their stiffness, making them easier to compress. This factor is crucial for applications operating in extreme temperature environments.

While the spring compression formula offers a powerful tool for understanding spring behavior, it's important to note that real-world springs exhibit a complex behavior that goes beyond the simple linear relationship implied by the formula.

For instance, springs can experience non-linear behavior at higher compression levels. This means that the relationship between force and displacement might deviate from a straight line, leading to higher compression than predicted by the formula.

Additionally, springs can exhibit hysteresis, meaning their compression and decompression cycles don't follow precisely the same path. This can lead to minor energy losses as the spring cycles through compression and release.

To understand these more complex aspects of spring behavior, engineers may employ advanced techniques like finite element analysis (FEA) or experimental testing. These methods can provide more detailed insights into the stress-strain relationships within a spring under various loading conditions.

The spring compression formula stands as a cornerstone of mechanical engineering, providing a powerful tool for understanding and predicting spring behavior. It allows engineers to design springs with the desired stiffness and compression characteristics for countless applications, from precision instruments to robust industrial machinery.

By carefully considering factors like spring material, geometry, load, and temperature, engineers can utilize the spring compression formula to achieve optimal spring performance. Understanding the limitations of the formula and exploring advanced techniques like FEA can further enhance our ability to analyze and design springs for complex and demanding applications.

As we navigate the world of springs, armed with the spring compression formula, we can confidently understand and control their behavior. From the delicate tick of a clock to the smooth ride of a car, springs play a vital role in our lives, and the formula empowers us to unlock their secrets and harness their power for countless innovations.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.