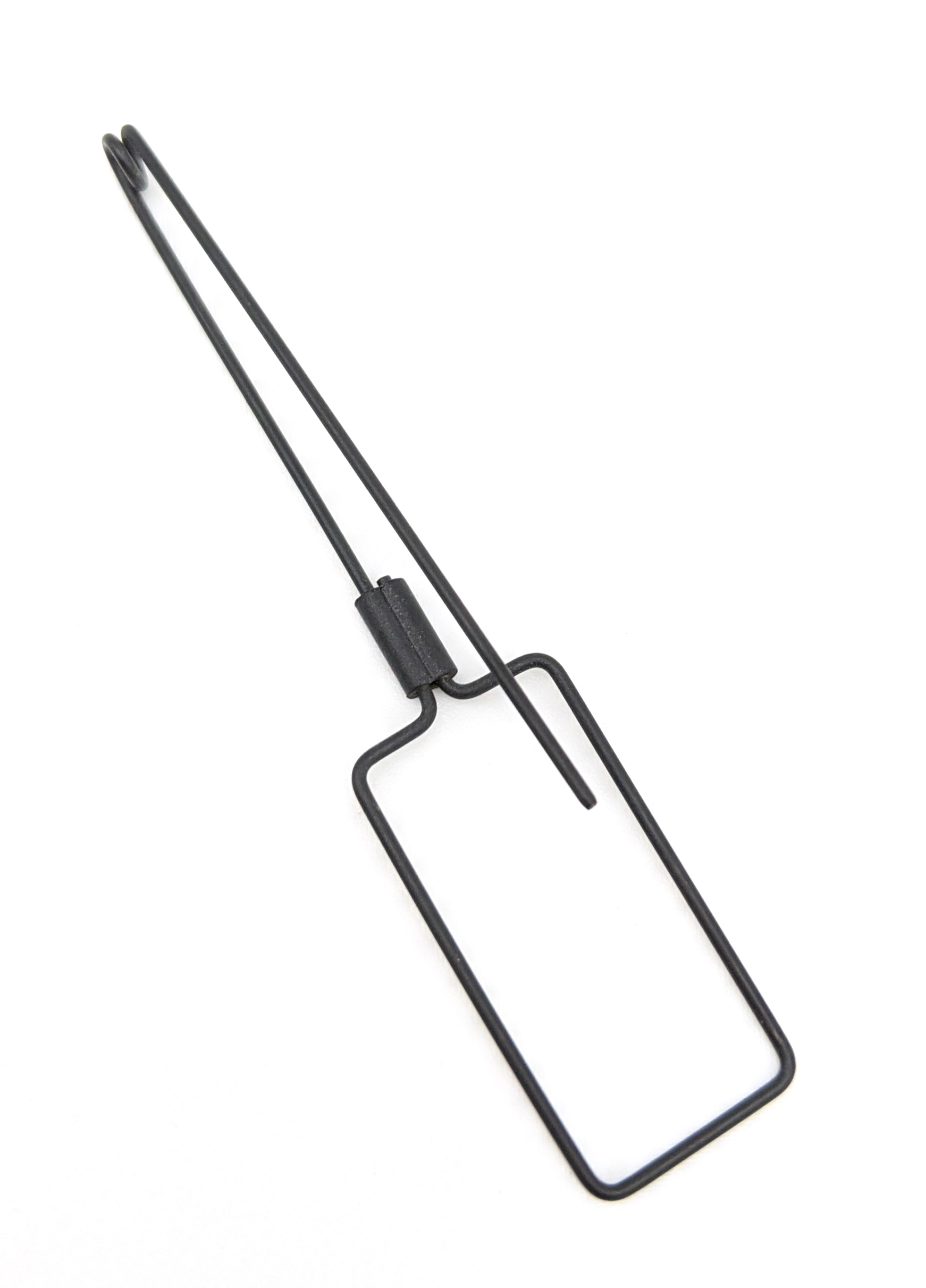

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, those coiled marvels of engineering, are ubiquitous in our daily lives, silently driving countless mechanisms. From the simple act of opening a door to the complex workings of

Torsion springs, those coiled marvels of engineering, are ubiquitous in our daily lives, silently driving countless mechanisms. From the simple act of opening a door to the complex workings of a car engine, torsion springs are the unsung heroes behind smooth, controlled movement. But understanding the magic behind these springs requires delving into the world of formulas, calculations, and design principles. This article serves as your comprehensive guide, exploring the fascinating world of torsion springs, from the fundamentals of their design to their diverse applications and the science behind their performance.

At their core, torsion springs are designed to store and release energy through twisting motion. They're essentially coiled wires that resist being twisted, much like a rubber band resists stretching. This resistance is what makes torsion springs so versatile, allowing them to power a wide range of mechanisms. Unlike extension or compression springs, which store energy by changing their length, torsion springs store energy by changing their angle of twist.

Think of it this way: Imagine winding a clock. The tighter you wind it, the more energy you store, and when you release it, the spring unwinds and releases that energy. This same principle applies to torsion springs, where the amount of torque or force they can exert is directly related to the amount of twist applied.

The key to understanding the behavior of a torsion spring lies in a simple but powerful formula. This formula allows engineers and designers to predict the spring's characteristics, like the torque it will generate at a given angle of twist, or the angle of twist required to achieve a desired torque. The formula is based on the following factors:

The formula itself is as follows:

Torque (T) = (G * d^4) / (8 * C * N) * θ

This formula allows us to predict how much torque a spring will generate for a given angle of twist. It's also crucial in designing springs to meet specific performance requirements.

Designing a torsion spring involves careful consideration of numerous factors, and the formula we discussed is merely one piece of the puzzle. Let's delve into some of the key aspects of torsion spring design:

The design process is iterative, involving testing and refinement to ensure the spring meets the desired specifications. Software tools can be invaluable in this process, allowing designers to simulate spring behavior and optimize its performance before physical prototyping.

Torsion springs, with their ability to store and release energy through twisting motion, find applications across a wide range of industries. From simple everyday items to complex machinery, their presence is evident in countless mechanical systems.

Let's explore a few examples of where torsion springs excel:

The versatility of torsion springs stems from their ability to adapt to various operating environments, handle different forces, and withstand various loads. They can be designed in countless configurations, ensuring that the right spring can be found for virtually any application.

The world of torsion springs is constantly evolving, with advancements in materials and manufacturing techniques continually pushing the boundaries of their performance. New alloys with enhanced strength, fatigue resistance, and corrosion resistance are being developed, enabling the creation of springs that can withstand even more demanding conditions.

Additive manufacturing, or 3D printing, is also revolutionizing the production of torsion springs, allowing for complex geometries and customized designs that were previously impossible. This opens up a whole new world of possibilities, where springs can be tailored to meet increasingly specialized needs.

Looking ahead, we can expect even more innovative applications of torsion springs in various industries. Their ability to store and release energy efficiently will continue to play a vital role in developing sustainable and environmentally friendly technologies. As we continue to explore the frontiers of science and engineering, torsion springs will undoubtedly remain at the forefront of mechanical design, driving innovation and pushing the limits of what's possible.

From the intricate workings of household appliances to the complex machinery of industries, torsion springs quietly power our world. By understanding the principles behind their design and the factors that influence their performance, we can unlock their full potential and utilize their remarkable capabilities to create more efficient, reliable, and sustainable technologies. So, the next time you encounter a torsion spring in action, take a moment to appreciate the science and ingenuity that lies behind its simple yet powerful operation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.