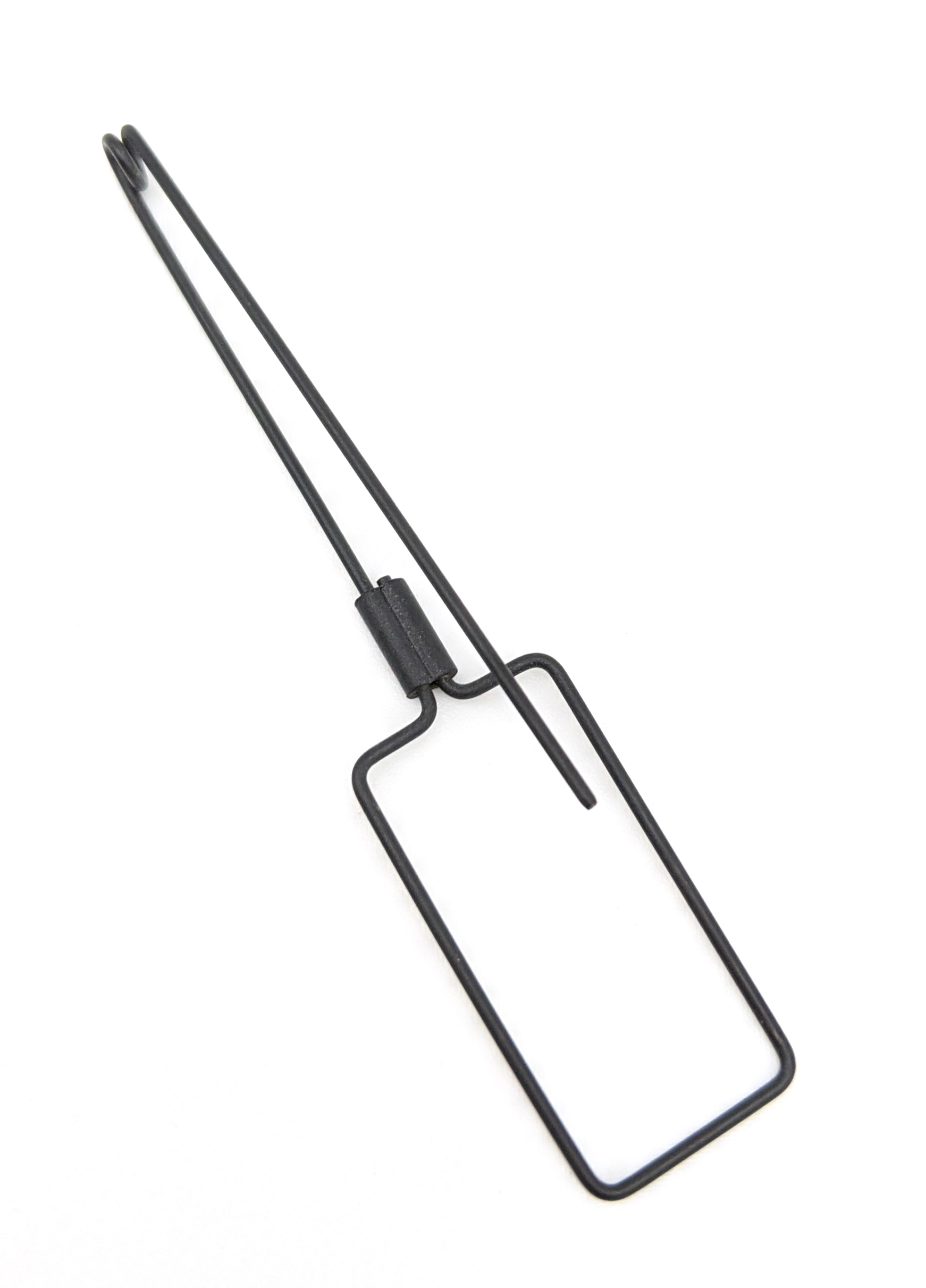

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered what makes a compressed spring so powerful? It's not just about the material it's made of, but the energy it stores within its coiled structure. This

Have you ever wondered what makes a compressed spring so powerful? It's not just about the material it's made of, but the energy it stores within its coiled structure. This stored energy, known as potential energy, is waiting to be released, ready to do work in various applications. From everyday objects like toys and door closers to sophisticated mechanisms in machines and vehicles, compressed springs play a vital role in our lives, quietly powering countless movements and processes.

Imagine a spring in its relaxed state, like a coiled-up snake ready to strike. When you compress it, you're forcing it into a smaller space, putting strain on its structure. This strain is what stores energy, like a tightly wound rubber band. The more you compress the spring, the more potential energy it accumulates.

The key to understanding this stored energy is the concept of elasticity. Springs are designed to be elastic, meaning they can return to their original shape after being deformed. This ability to stretch and rebound is what allows springs to store and release energy efficiently. When you release the pressure on a compressed spring, it snaps back to its original shape, transforming that stored potential energy into kinetic energy, or the energy of motion.

The way a compressed spring releases its stored energy is pretty simple. As you release the pressure, the spring's internal forces push it back to its original position. This push creates a force, which in turn, performs work. Think of a spring-loaded toy: when you release the spring, the stored energy propels the toy forward. Or consider a car's suspension system, where springs absorb the impact of bumps and potholes, providing a smooth ride.

There are two main types of springs you'll typically encounter: coil springs and leaf springs. Coil springs are the ones we usually envision - a helical structure made of wire. Leaf springs, on the other hand, are made of a series of flat metal strips stacked on top of each other. Both types store energy through compression, but they work differently in practice.

The amount of energy a spring can store depends on a few factors: its material, the spring's diameter, the number of coils, and the amount of compression it undergoes. The stronger the material, the more energy it can hold. A larger diameter and more coils also increase storage capacity. And, naturally, the more you compress the spring, the more potential energy it gathers.

Compressed springs are ubiquitous, powering countless applications. Here are just a few examples:

1. **Mechanical Devices:** From simple door closers and spring-loaded hinges to sophisticated mechanisms in watches and clocks, compressed springs drive movement and control force.

2. **Automotive Industry:** Springs play a critical role in cars, trucks, and motorcycles. They absorb shocks and bumps, provide suspension, and power the clutch and brakes.

3. **Industrial Machinery:** In factories and workshops, compressed springs are essential for powering actuators, controlling motion in robotics, and providing tension in conveyor belts.

4. **Consumer Products:** Springs power everything from toys and ballpoint pens to the opening and closing mechanisms of appliances like refrigerators and washing machines.

5. **Medical Devices:** Compressed springs are used in a variety of medical devices, like medical instruments, surgical equipment, and even artificial heart valves.

Compressed springs offer numerous advantages that make them valuable in a wide range of applications:

1. **Reliability:** Springs are highly reliable, designed to withstand repeated cycles of compression and release without losing their ability to store energy.

2. **Durability:** They're typically made from strong materials that can withstand wear and tear, ensuring longevity in demanding applications.

3. **Energy Efficiency:** Springs offer an efficient way to store and release energy, minimizing energy loss during operation.

4. **Simple Design:** Their design is relatively straightforward, making them easy to manufacture and integrate into different systems.

5. **Cost-Effectiveness:** Compressed springs are generally cost-effective, making them a popular choice for various industries.

Understanding how compressed springs work is crucial, not just for engineers and designers but for anyone interested in the world around us. From the simple act of opening a door to the complex mechanics of a spacecraft, compressed springs are quietly working behind the scenes, powering our lives and driving innovation.

By appreciating the power of stored energy within these humble coils, we gain a deeper understanding of the fundamental principles of mechanics and engineering. It's a reminder that even seemingly simple things can hold immense potential, waiting to be unleashed in countless ways.

Compressed springs are a testament to the ingenuity of human design. They harness the power of stored energy, transforming it into useful work in countless ways. From the simple act of opening a door to the complex mechanics of sophisticated machinery, these springs continue to play a vital role in our modern world. By understanding their principles, we gain a deeper appreciation for the forces that shape our everyday lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.