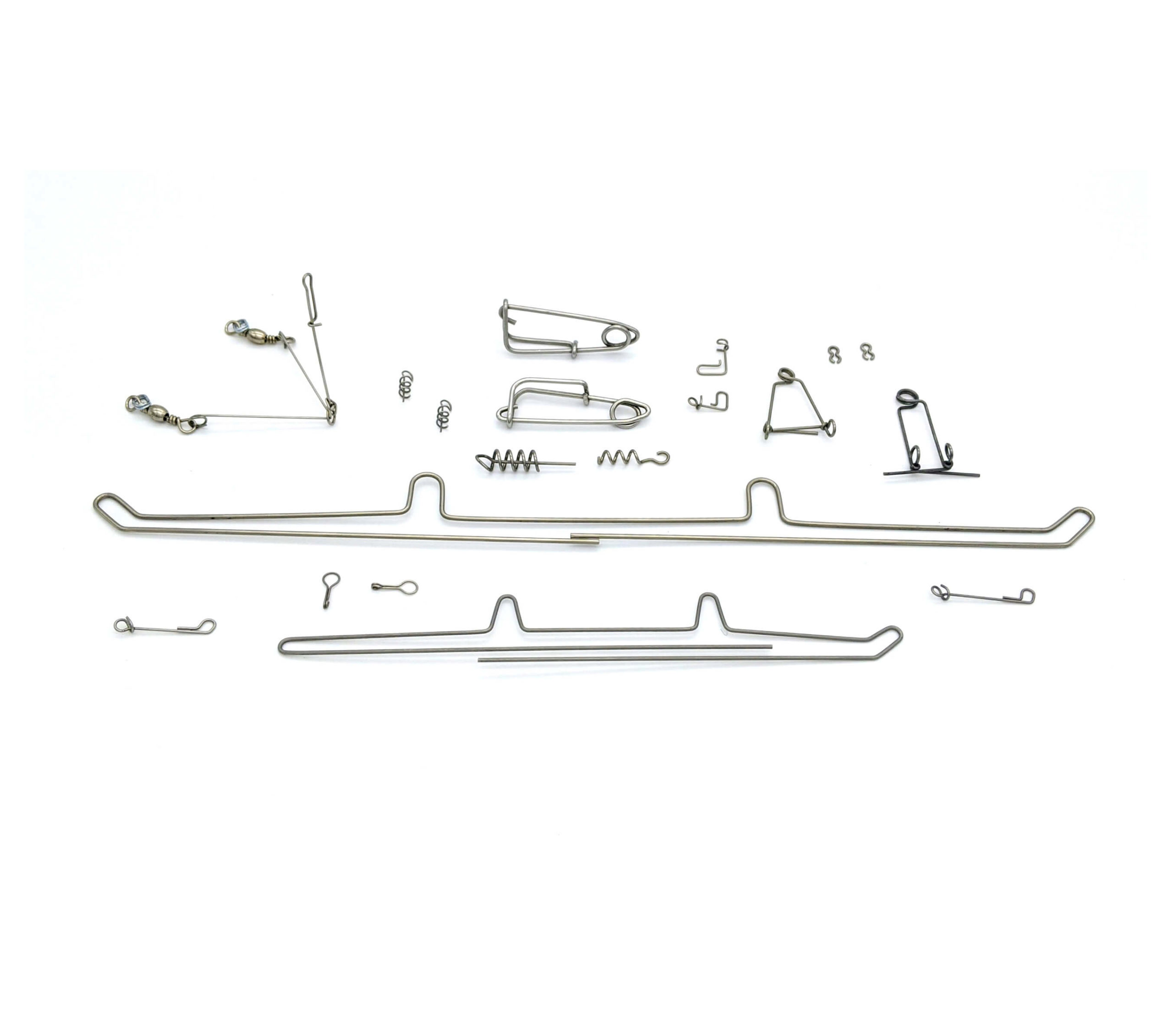

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous components found in everything from car suspensions to door hinges, play a crucial role in our daily lives. Their ability to store and release energy is fundamental

Springs, those ubiquitous components found in everything from car suspensions to door hinges, play a crucial role in our daily lives. Their ability to store and release energy is fundamental to countless mechanical systems. A key parameter in spring design is the maximum compression, which determines the spring's safe operating limit. This article delves into the intricate relationship between spring properties, applied force, and maximum compression, offering a clear and comprehensive understanding of this essential concept.

Before diving into the nitty-gritty of maximum compression calculations, let's first grasp the underlying principles governing spring behavior. At its core, a spring is a device that exhibits elasticity, meaning it can deform under load and return to its original shape when the load is removed. This elastic behavior is characterized by Hooke's Law, a fundamental principle that states the force exerted by a spring is directly proportional to its displacement from its equilibrium position. In simpler terms, the more you compress or extend a spring, the greater the force it will push back with.

However, every spring has a limit. There's a point beyond which the spring can no longer deform elastically and will permanently deform or even break. This critical point is known as the maximum compression, and it's crucial to understand it for safe and reliable spring operation. Exceeding the maximum compression can lead to spring failure, potentially causing malfunctions or safety hazards.

The maximum compression of a spring is determined by several factors, including its material properties, design parameters, and the applied load. Fortunately, a simple yet powerful formula allows us to calculate this critical value. Let's break down the formula and its components:

**Formula:** Maximum Compression = (Free Length - Solid Height) / (1 + (Force / Spring Rate))

**Components:**

The concept of maximum compression is not merely theoretical; it has numerous practical applications across various industries and disciplines. Let's explore a few key scenarios where understanding maximum compression is essential:

While the maximum compression formula provides a valuable foundation, it's important to note that real-world spring design often involves additional factors that can influence spring behavior and its maximum compression limit. These include:

The maximum compression of a spring is a fundamental parameter that defines its safe operating limits. By understanding the factors that influence maximum compression and utilizing the formula provided, engineers, designers, and technicians can ensure the proper selection, sizing, and application of springs for various applications. Whether in automotive systems, aerospace engineering, or medical devices, the knowledge of maximum compression serves as a cornerstone for safe and effective spring use, promoting reliability and preventing potential failures.

In conclusion, understanding the maximum compression of a spring is crucial for its safe and efficient operation. By carefully considering the spring's properties, the applied force, and the formula provided, we can ensure that springs are properly sized and used within their safe operating limits. This knowledge is essential for reliable performance in a wide range of applications, from everyday mechanical systems to demanding aerospace and medical technologies. Remember, respecting the maximum compression of a spring is key to avoiding failures and maintaining the integrity of critical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.