Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered why a spring bounces back to its original shape after being compressed or stretched? The answer lies in a fundamental principle of physics known as Hooke's

Have you ever wondered why a spring bounces back to its original shape after being compressed or stretched? The answer lies in a fundamental principle of physics known as Hooke's Law. This law describes the relationship between the force applied to a spring and its resulting deformation, providing a crucial framework for understanding the behavior of elastic materials. In this article, we'll delve into the intricacies of Hooke's Law, exploring its mathematical representation and its applications in various fields, from everyday objects to advanced engineering designs.

Imagine you have a spring and you start to compress it. You'll notice that the more you push, the harder it becomes to compress it further. This resistance to compression is directly proportional to the amount of compression. This relationship, beautifully encapsulated in Hooke's Law, states that the force required to compress or stretch a spring is directly proportional to the displacement from its equilibrium position.

Mathematically, Hooke's Law is expressed as:

F = -kx

Where:

The negative sign indicates that the force exerted by the spring opposes the displacement. So, if you compress the spring (x is positive), the spring will exert a force pushing back (F is negative), and vice versa.

The spring constant, 'k', is a crucial parameter that defines the spring's stiffness. A higher spring constant means the spring is stiffer and requires a greater force to compress or stretch it. Imagine a heavy-duty spring used in a car suspension system versus a delicate spring found in a toy. The car suspension spring would have a much higher spring constant due to its need to withstand heavier loads.

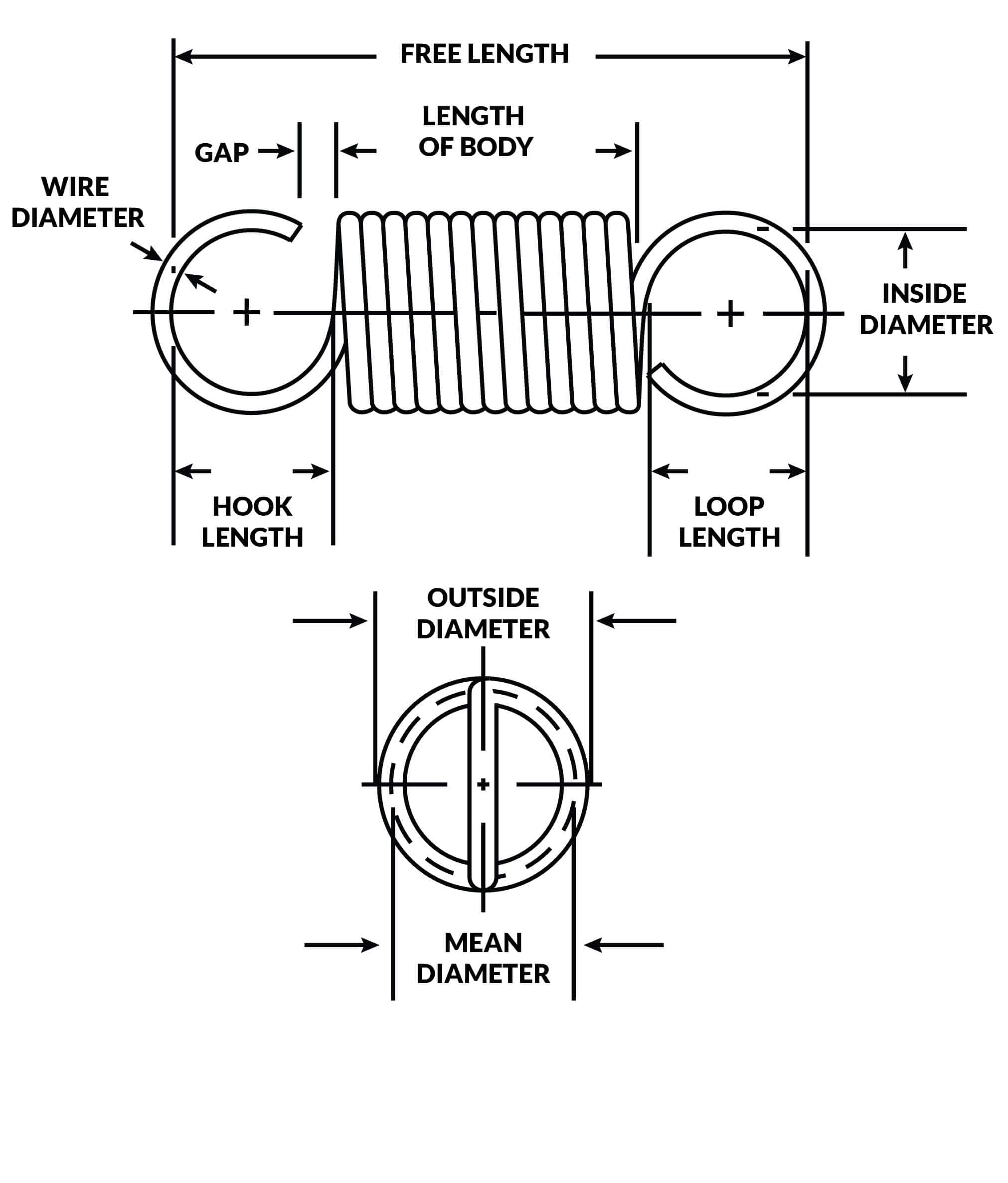

The spring constant depends on the material of the spring, its geometry (like the wire diameter and the number of coils), and the way it's manufactured. Determining the spring constant experimentally involves measuring the force required to compress or stretch the spring by a known displacement.

Hooke's Law might seem like a simple concept, but its applications are far-reaching and impact numerous aspects of our daily lives.

While Hooke's Law provides a fundamental understanding of spring behavior, it's important to acknowledge its limitations. Real-world springs don't always behave perfectly according to this law, especially when subjected to extreme conditions.

Elastic Limit: Hooke's Law holds true only within the elastic limit of the spring material. Beyond this limit, the spring experiences permanent deformation and may not return to its original shape. Think about bending a paperclip – you can bend it back and forth a few times, but after a certain point, it'll stay bent.

Non-Linearity: Some springs exhibit non-linear behavior, meaning the force required to compress or stretch them isn't directly proportional to the displacement. This occurs when the material properties of the spring change under stress.

Let's consider a practical example to highlight the importance of understanding spring compression: Imagine you're designing a shock absorber for a car. You need to ensure the shock absorber can absorb the impact of bumps and potholes without causing excessive vibrations or damage to the car. This involves carefully selecting a spring with the right spring constant to provide appropriate resistance to compression.

If the spring constant is too low, the shock absorber will compress too much, resulting in a bouncy ride. On the other hand, if the spring constant is too high, the shock absorber will be too stiff, leading to a jarring ride and potential damage to the car's suspension. This example illustrates the crucial role of spring compression and its impact on various engineering designs.

As technology advances, we are developing new materials and techniques that go beyond the limitations of traditional spring systems. For example, researchers are exploring shape-memory alloys that can remember their original shape and return to it after being deformed. These advancements are paving the way for more innovative and efficient spring-like systems with enhanced performance and functionality.

In conclusion, understanding the compression of a spring is crucial in various fields, from simple everyday applications to complex engineering designs. Hooke's Law provides a fundamental framework for grasping the relationship between force and displacement in elastic materials. While it's essential to recognize the limitations of this law, particularly under extreme conditions, it remains a cornerstone in understanding the behavior of springs and their widespread applications. As we continue to explore and innovate, we can expect to see even more fascinating applications of spring compression in the future, shaping our world in remarkable ways.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.