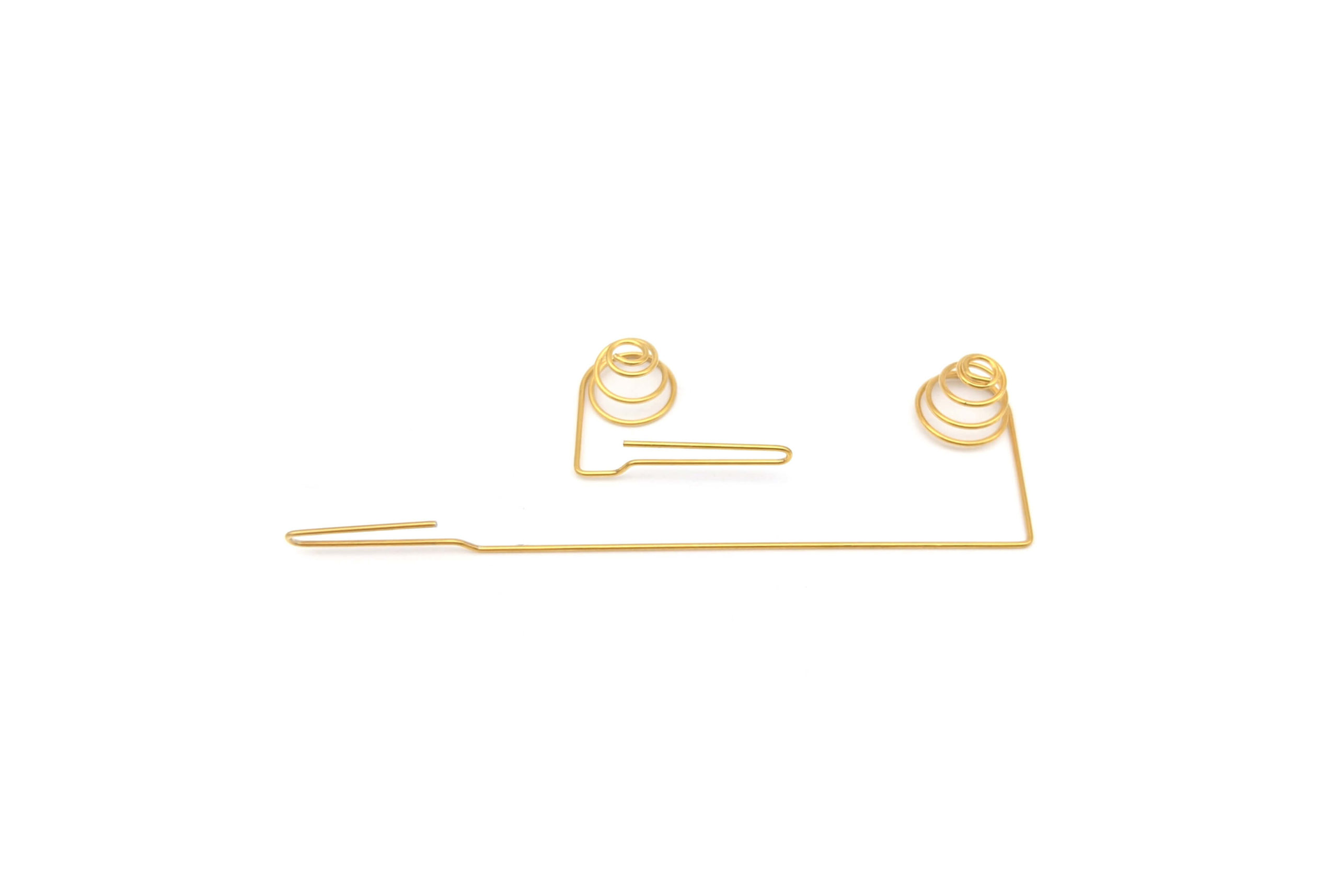

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous components found in countless mechanical devices, play a critical role in storing and releasing energy. One crucial aspect of spring design and application is determining the maximum

Springs, those ubiquitous components found in countless mechanical devices, play a critical role in storing and releasing energy. One crucial aspect of spring design and application is determining the maximum compression they can withstand before experiencing permanent deformation or failure. This article delves into the concept of maximum compression, exploring the underlying principles, factors influencing it, and the formula used to calculate this crucial parameter. Understanding maximum compression is essential for ensuring the safe and efficient operation of spring-based systems.

Maximum compression, in essence, represents the limit to which a spring can be compressed before its physical structure is compromised. Beyond this limit, the spring might not return to its original shape, leading to malfunction or even failure. This limit is not arbitrarily set but is determined by a complex interplay of factors that define the spring's material properties, design characteristics, and the intended application.

Several key factors influence the maximum compression a spring can handle. These factors include:

The maximum compression of a spring can be calculated using a specific formula that takes into account the spring's geometry and material properties. The most common formula used for this purpose is:

Maximum Compression (δmax) = (Fmax * L) / (k * G * d4)

Where:

This formula provides a theoretical estimate of maximum compression. In practice, it's important to consider safety factors and the specific application requirements to ensure the spring's reliable operation. Always consult engineering specifications and relevant standards for guidance.

The concept of maximum compression is fundamental in various engineering applications, including:

While maximum compression is a critical aspect of spring design, it's not the only factor determining their lifespan. Other factors like fatigue, corrosion, and environmental influences can affect spring performance. Regular inspection, maintenance, and proper lubrication are crucial for maximizing spring longevity and ensuring their continued reliable operation.

The maximum compression of a spring is a crucial parameter that engineers and designers must consider during the design and application of spring-based systems. Understanding the factors that influence this limit, utilizing the appropriate calculation formulas, and adhering to safety factors are essential for ensuring the safe, efficient, and long-lasting performance of springs in various applications. By appreciating the importance of maximum compression, we can optimize the use of these essential mechanical components in our everyday lives.

In conclusion, understanding the concept of maximum compression is essential for ensuring the reliable and safe performance of springs. By taking into account factors like spring material, design, and loading conditions, and employing appropriate formulas, engineers can design spring-based systems that operate efficiently and withstand the demands of their intended applications. Moreover, by implementing proper maintenance practices and considering the broader context of spring longevity, we can maximize the lifespan and effectiveness of these vital components in our world of machinery.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.