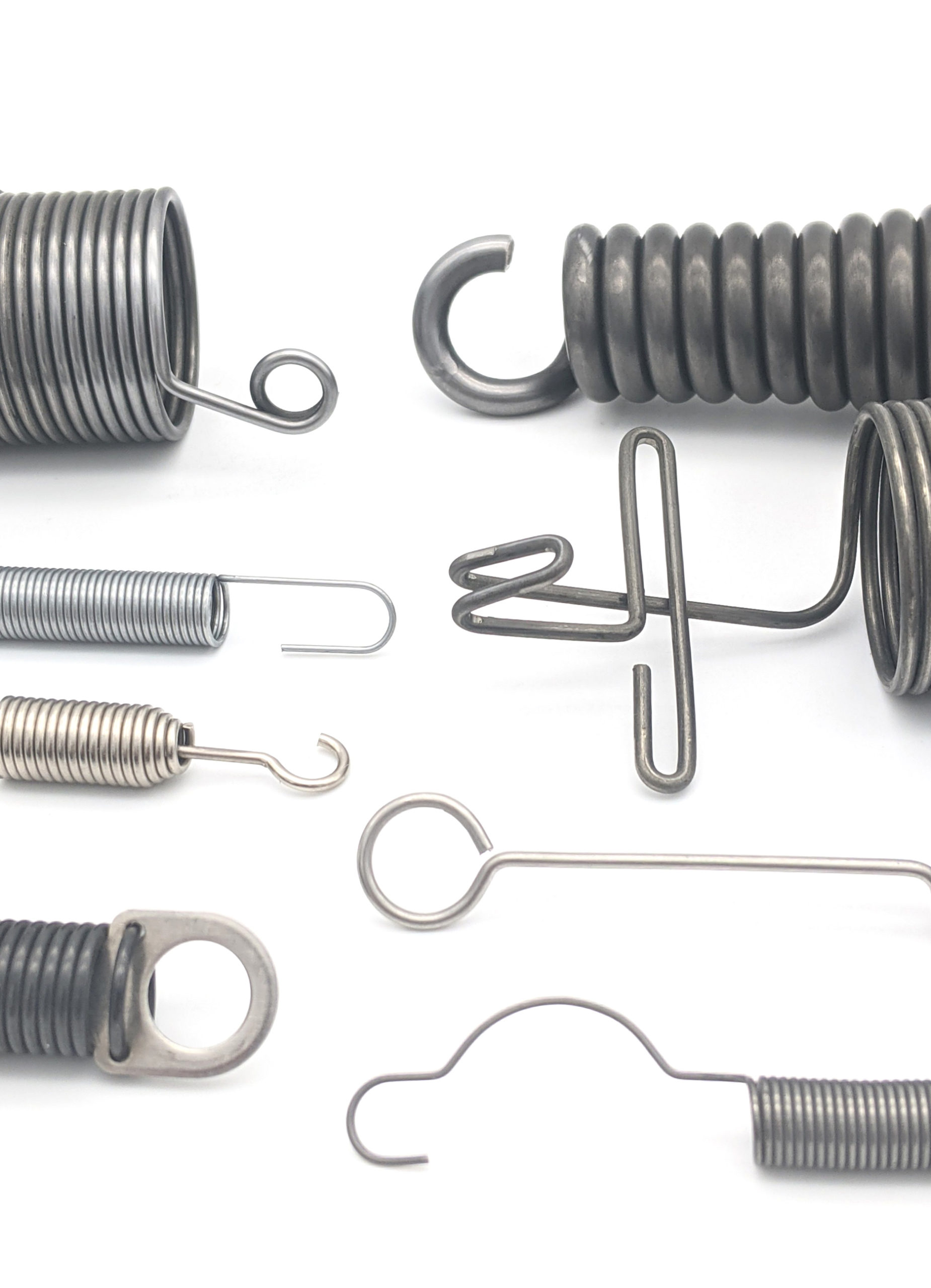

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsional springs, often overlooked in the vast world of mechanical components, play a crucial role in countless applications. These ingenious devices store and release energy through twisting motion, providing a

Torsional springs, often overlooked in the vast world of mechanical components, play a crucial role in countless applications. These ingenious devices store and release energy through twisting motion, providing a reliable and efficient means to control movement, provide feedback, and even generate power. From the delicate mechanism of a watch to the robust operation of industrial machinery, torsional springs are silently working behind the scenes, ensuring smooth and precise functionality. In this article, we delve into the fascinating world of torsional springs, exploring their design, principles, applications, and the factors that govern their performance.

Imagine a coiled wire, not stretched or compressed, but twisted. This is the essence of a torsional spring. Its ability to store energy lies in its resistance to being twisted, much like a rubber band resists being stretched. The spring's resistance to this twisting force is quantified as its torsional stiffness, a measure of how much torque is required to twist the spring by a specific angle.

Torsional springs come in various forms, each suited to a specific application. Some common types include:

The behavior of a torsional spring is governed by the laws of elasticity, specifically Hooke's law. This law states that the torque required to twist a spring is directly proportional to the angle of twist. This relationship holds true within the spring's elastic limit, beyond which it may deform permanently.

The torsional stiffness of a spring is dependent on several factors, including:

Torsional springs are ubiquitous in various industries, serving diverse purposes. Here are some key applications:

Selecting the right torsional spring for an application involves carefully considering several factors:

The correct spring selection ensures reliable operation, extended lifespan, and optimized performance. It's often advisable to consult with a spring manufacturer or engineer to ensure the right choice for your specific needs.

Torsional springs offer several advantages that make them highly versatile and valuable components:

While torsional springs offer numerous benefits, there are a few points to keep in mind:

The world of torsional springs is constantly evolving, with new materials and manufacturing processes emerging. Advanced materials like composites and shape memory alloys are being explored for improved performance and durability. The use of simulation software is enhancing spring design and analysis, enabling more precise optimization and customization. As technology advances, we can expect torsional springs to play an even more vital role in a wider range of applications, contributing to innovation and progress in various fields.

Torsional springs, despite their often-unseen nature, are vital components that enable smooth and precise motion in countless devices and systems. Their ability to store and release energy through twisting motion makes them indispensable in industries ranging from watchmaking to aerospace. As we continue to push the boundaries of technology, the versatility and reliability of torsional springs will likely become even more critical in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.