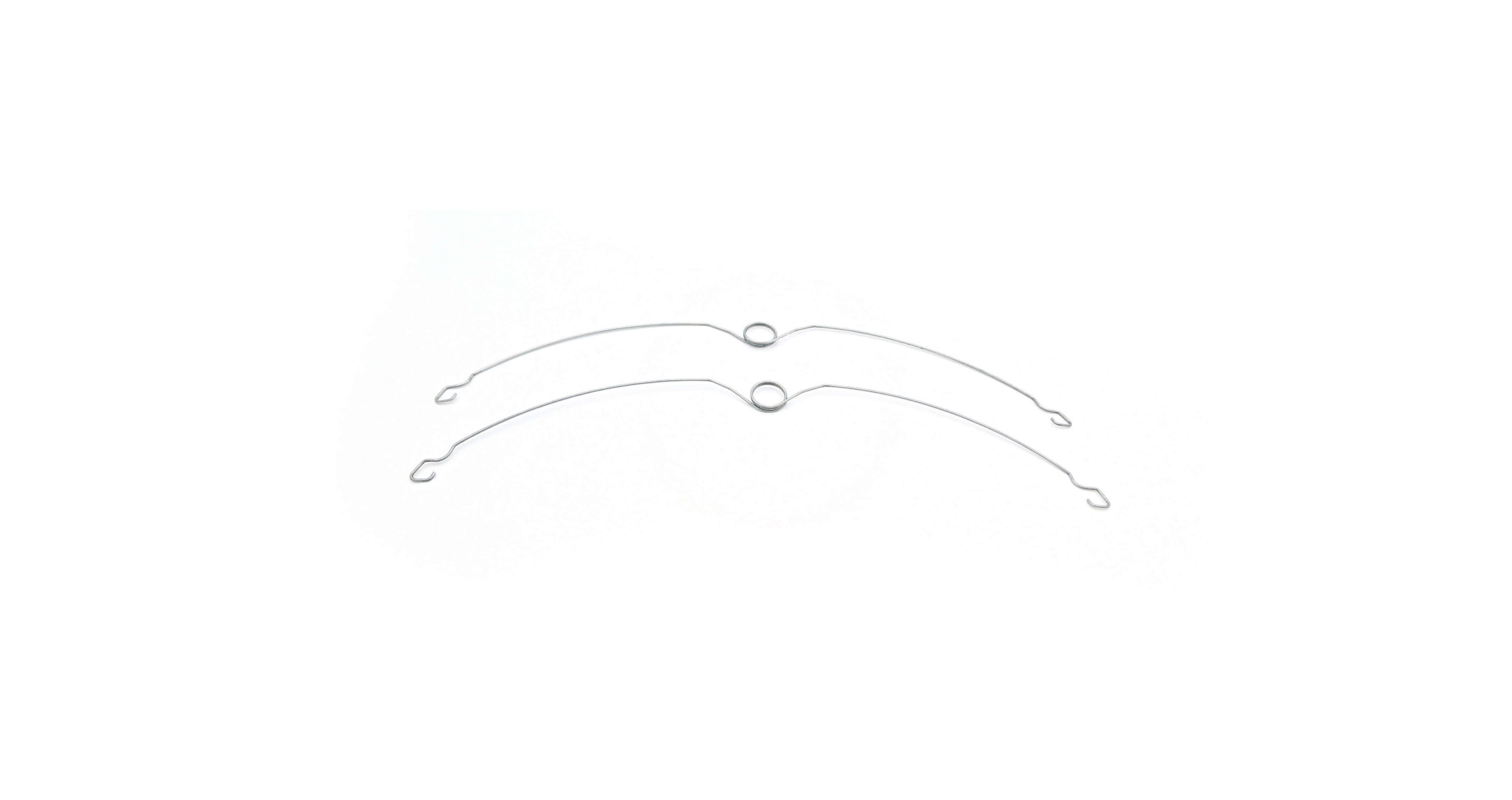

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical systems, springs are often the silent workhorses, quietly ensuring smooth operation and absorbing shock. But one particular type, the torsional spring, plays a vital role

In the world of mechanical systems, springs are often the silent workhorses, quietly ensuring smooth operation and absorbing shock. But one particular type, the torsional spring, plays a vital role that often goes unnoticed. This seemingly simple device, capable of storing and releasing rotational energy, is a crucial component in countless applications, from everyday appliances to complex machinery. In this article, we will delve into the fascinating world of torsional springs, exploring their design, working principles, and their indispensable contributions to our technological landscape.

Imagine a spring that, instead of compressing or extending, twists and untwists. That's essentially what a torsional spring is. It's a coiled wire or a helical spring designed to resist and store rotational forces. As a torque is applied to the spring, it winds or unwinds, storing energy in the process. Once the torque is released, the spring attempts to return to its original state, delivering the stored energy back into the system. This simple yet powerful principle makes torsional springs essential in a wide range of mechanical designs.

While the concept might seem straightforward, the design of a torsional spring can be quite intricate. The key elements are:

The working principle of a torsional spring hinges on the concept of torsional stress. When a torque is applied to the spring, the wire experiences a twisting force. This force creates internal stresses within the wire, and the spring deforms to accommodate the applied torque. The amount of deformation, or twist, is directly proportional to the applied torque. This relationship is defined by the spring's torsional stiffness, which is a measure of its resistance to twisting.

Torsional springs are ubiquitous in mechanical systems, making their presence felt in a wide array of applications. Here are just a few examples:

The design and selection of torsional springs require careful consideration of various factors. Some key aspects to keep in mind include:

The demand for torsional springs continues to grow as technology evolves and new applications emerge. Advanced materials, such as shape memory alloys and composites, are being explored to create springs with enhanced properties, such as greater strength, lighter weight, and improved resilience. Researchers are also investigating new manufacturing methods, like 3D printing, to create intricate and customized torsional springs for specific applications.

From their humble beginnings in simple mechanisms to their sophisticated roles in advanced technologies, torsional springs have quietly played a vital role in shaping our world. They are a testament to the power of seemingly simple concepts to achieve remarkable results. As technology continues to advance, we can expect torsional springs to continue evolving, finding new applications and helping us push the boundaries of what's possible in engineering and design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.