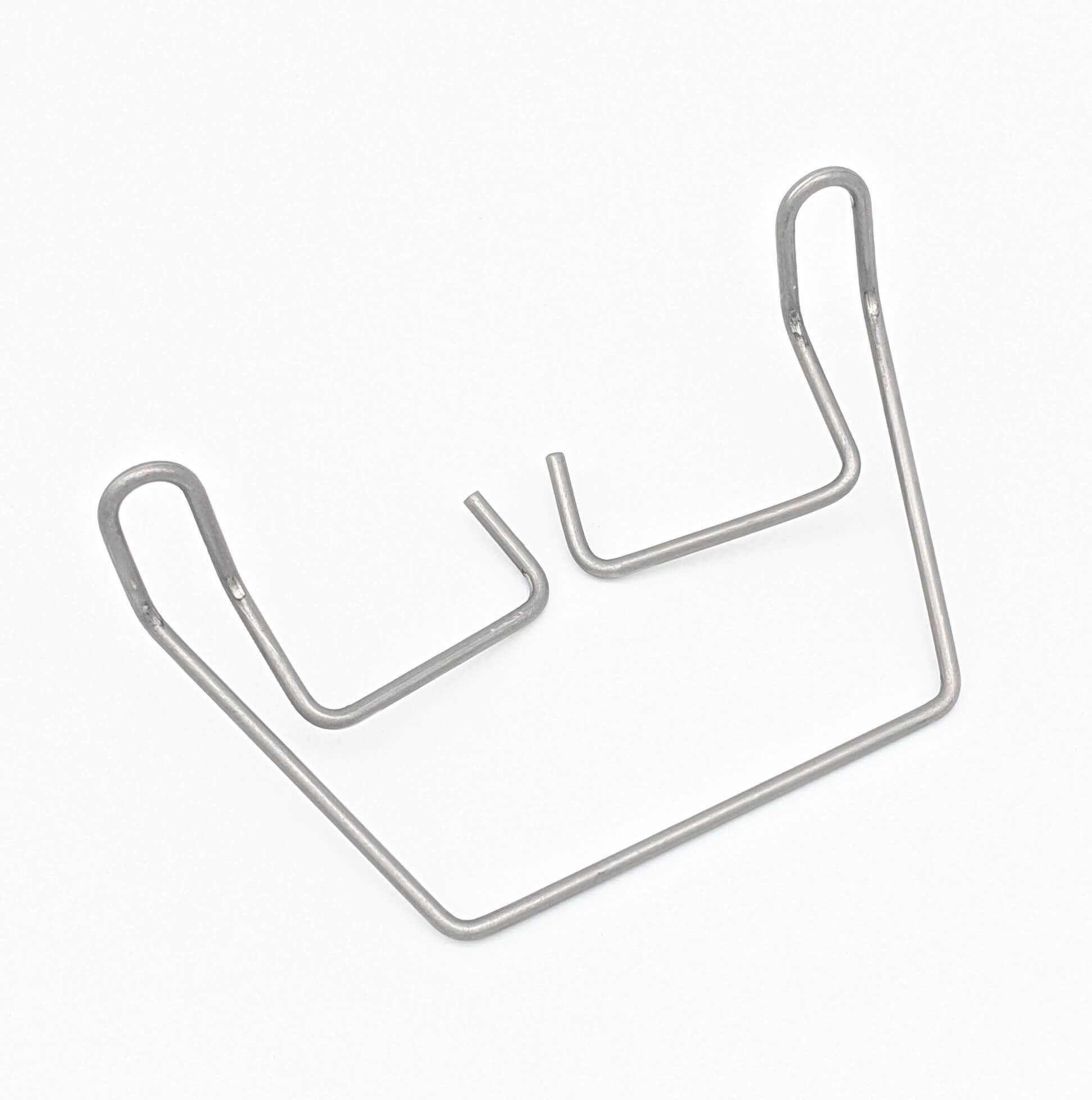

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsional springs, often overlooked in the grand scheme of mechanical systems, play a crucial role in countless applications. These unassuming devices, essentially coiled wires designed to resist twisting, are the

Torsional springs, often overlooked in the grand scheme of mechanical systems, play a crucial role in countless applications. These unassuming devices, essentially coiled wires designed to resist twisting, are the silent guardians of smooth and precise movement, ensuring that everything from automotive engines to medical devices operates efficiently and reliably. Though often hidden from view, their presence is felt in the delicate hum of a watch, the powerful torque of a drill, and the precision of a robotic arm.

At their core, torsional springs are designed to store and release energy through twisting. They are typically made of high-quality metal wire, meticulously coiled to achieve a specific spring rate. This spring rate, measured in units of torque per angle, dictates the amount of force the spring exerts for a given amount of rotation. The higher the spring rate, the stiffer the spring, and the more force it requires to twist.

Unlike their linear counterparts, which store energy through compression or extension, torsional springs find their application in rotational systems. Imagine a coiled spring attached to a shaft, where one end of the shaft is fixed. As you apply a torque to the shaft, the spring resists this twisting motion, storing the energy like a coiled-up spring. When the applied torque is released, the stored energy is released, forcing the shaft to rotate back to its original position.

The versatility of torsional springs allows them to be incorporated into a vast array of applications, often playing critical roles in ensuring the smooth and precise operation of mechanical systems. Here are some key examples:

1. Automotive Industry: Torsional springs are crucial in automotive engines, where they provide the necessary torque to open and close valves at precise moments during the combustion cycle. They also find their way into steering mechanisms, ensuring smooth and responsive steering input, and into suspension systems, where they help control the movement of wheels for a comfortable ride.

2. Aerospace and Defense: In aerospace and defense applications, where precision is paramount, torsional springs play a vital role in stabilizing and controlling the movement of various components. They are used in actuators, controlling the movement of flaps and rudders on aircraft, and in precision guidance systems, ensuring accurate targeting and positioning.

3. Medical Devices: The healthcare industry relies heavily on torsional springs for various medical devices. They are integral to instruments used in surgeries, providing the necessary torque to control delicate movements. They are also found in prosthetic limbs, ensuring smooth and natural movement, and in medical pumps, controlling the flow of fluids.

4. Consumer Electronics: In the world of consumer electronics, torsional springs are responsible for the smooth operation of countless devices. They are found in smartphones, powering the tactile feedback of buttons, and in laptops, ensuring smooth and silent movement of hinges.

When designing with torsional springs, several factors come into play to ensure optimal performance and longevity. These include:

1. Material Selection: The choice of material is crucial, as it dictates the spring's strength, durability, and resistance to fatigue. High-quality spring steels are often preferred for their resilience and resistance to wear and tear.

2. Spring Rate: Determining the appropriate spring rate is essential for the desired performance. A spring rate that is too high can lead to excessive stiffness and difficulty in movement, while a spring rate that is too low may result in instability or lack of precision.

3. End Fixings: The way in which the spring is attached to the system is critical. Various end fixings, such as hooks, loops, or eyes, are available, and the choice depends on the specific application and the required loading conditions.

4. Environmental Considerations: The operating environment must also be considered. Temperature variations, corrosive substances, and other environmental factors can affect the performance and longevity of the spring.

While torsional springs have proven their value in countless applications, they also face certain challenges, including:

1. Fatigue and Wear: Over time, torsional springs can experience fatigue due to repeated loading and unloading, leading to a gradual loss of spring rate and potential failure. Materials research and advanced manufacturing techniques are constantly being explored to enhance the fatigue resistance of these springs.

2. Miniaturization: As electronic devices become increasingly smaller and more intricate, the demand for miniature torsional springs is growing. Developing new manufacturing methods and materials to create springs with ever-smaller dimensions poses a significant challenge.

3. Sustainability: There is a growing emphasis on sustainability in manufacturing, and the production of torsional springs is no exception. Efforts are underway to develop more sustainable manufacturing processes and explore the use of recycled materials.

Despite these challenges, the future of torsional springs is bright. Advances in materials science, manufacturing technology, and computer modeling are leading to the development of even more efficient and durable springs. These innovations are opening doors to new and exciting applications, further expanding the reach and impact of these unassuming yet essential mechanical components.

Torsional springs are often hidden behind the scenes, but their contribution to the smooth and precise operation of countless mechanical systems is undeniable. From the intricate mechanisms of watches to the robust power of automotive engines, they are the unsung heroes, silently ensuring that our world keeps turning. As technology continues to advance, the role of torsional springs will only become more critical, shaping the future of countless industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.