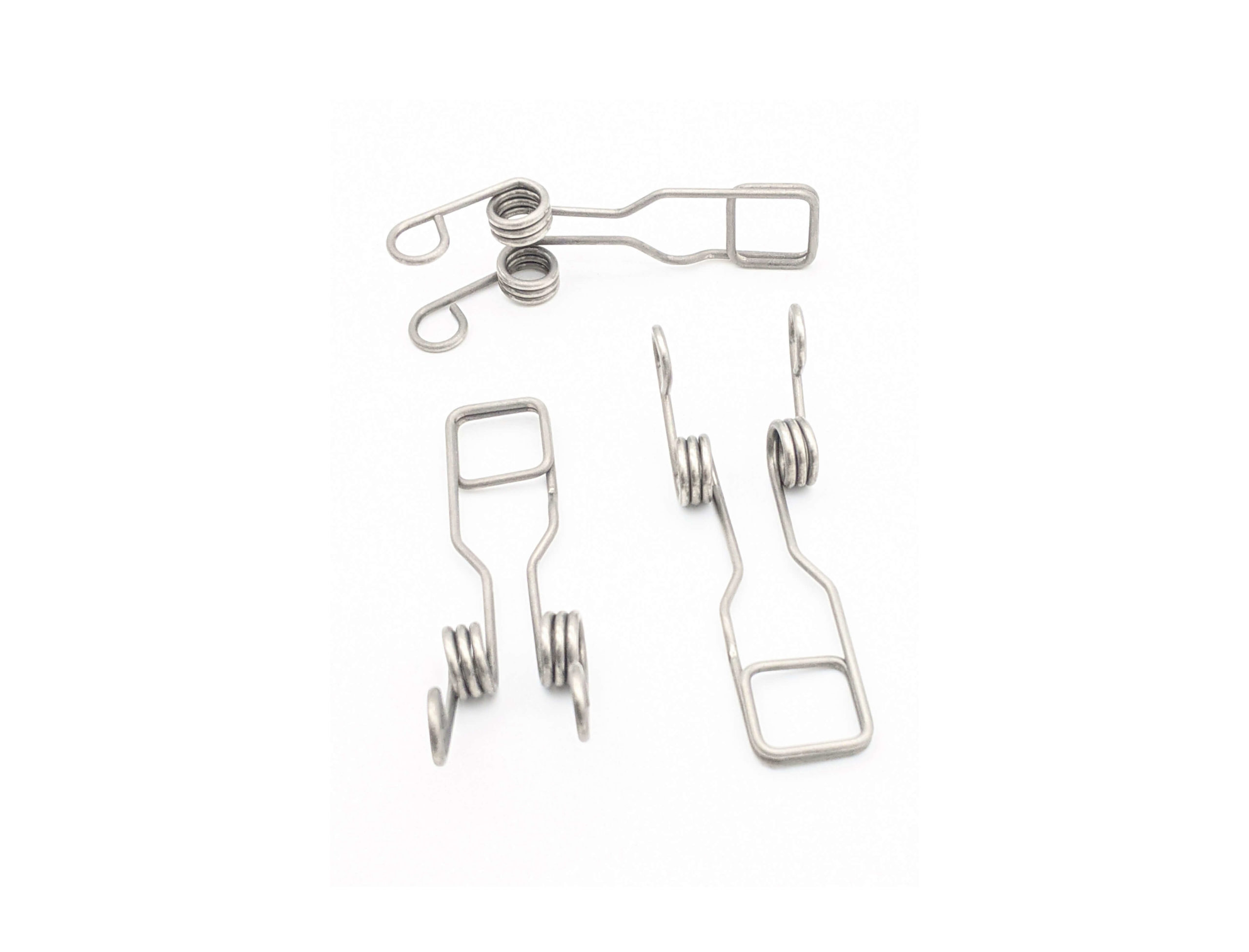

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without the smooth, silent turning of a car's steering wheel, the precise movement of a watch's hands, or the effortless opening of a door. These seemingly mundane

Imagine a world without the smooth, silent turning of a car's steering wheel, the precise movement of a watch's hands, or the effortless opening of a door. These seemingly mundane actions rely on a crucial component often overlooked: the torsional spring. These unsung heroes of mechanical design quietly work behind the scenes, providing the restoring force that enables rotation and control in countless applications. This article delves into the fascinating world of torsional springs, exploring their principles, diverse applications, and the essential role they play in our modern world.

At their core, torsional springs are simply coiled wires designed to resist twisting or rotation. Unlike their linear counterparts, which resist stretching or compression, torsional springs store energy when they are twisted, and release that energy when allowed to return to their original position. This ability to store and release rotational energy makes them invaluable in numerous mechanical systems.

The key to a torsional spring's performance lies in its design. The diameter and material of the wire, the number of coils, and the spring's overall geometry all influence its stiffness, or its resistance to twisting. A stiffer spring requires more force to twist, while a less stiff spring can be twisted more easily. This adjustable stiffness is a key advantage of torsional springs, allowing them to be tailored to specific applications.

The versatility of torsional springs is truly remarkable. They are found in a vast array of applications, ranging from the intricate mechanisms of watches and clocks to the robust systems of automobiles and industrial machinery.

In automotive applications, torsional springs are critical components in steering wheels, door hinges, and suspension systems. They provide the restoring force needed for smooth steering, controlled door movement, and a comfortable ride. In watches and clocks, torsional springs are used to power the movement of the hands, ensuring precise timekeeping. These small but essential springs are responsible for the delicate balance and consistent rhythm of these mechanical marvels.

Beyond these familiar examples, torsional springs play an essential role in countless other areas. They are used in appliances like refrigerators and washing machines to provide smooth and controlled movement. They are also crucial in industrial machinery, where they provide the precise torque needed for automated processes, and in medical devices like surgical instruments, ensuring smooth and precise operations.

Torsional springs offer a number of advantages that make them the preferred choice in many design scenarios. Their compact size and ability to fit into tight spaces are highly valuable in situations where space is at a premium. Their high resistance to fatigue and wear ensures long-lasting performance, even under demanding conditions. Moreover, they are relatively inexpensive to manufacture, making them a cost-effective solution for a wide range of applications.

One of the most significant advantages of torsional springs is their ability to provide a precise and predictable force. This predictability is essential in applications where controlled movement and accurate positioning are critical, such as in robotics, aerospace, and precision manufacturing.

The demand for torsional springs continues to grow as industries seek innovative and reliable solutions for their mechanical systems. Advancements in materials science are leading to the development of new spring alloys with enhanced properties, such as increased strength, reduced weight, and improved corrosion resistance. These advancements are paving the way for even more innovative and efficient applications of torsional springs.

Furthermore, the integration of torsional springs into smart systems is gaining momentum. By combining these springs with sensors and actuators, designers can create intelligent mechanical systems that can adapt to changing conditions and perform complex tasks with greater efficiency and accuracy. This convergence of mechanical design and smart technologies is poised to unlock exciting new possibilities for the application of torsional springs in the future.

Torsional springs may be small and often hidden from view, but their impact on our daily lives is undeniable. From the smooth operation of our cars to the precise movements of our watches, these remarkable components silently ensure the functionality of countless mechanical systems. As technology advances and new applications emerge, the role of torsional springs will continue to grow, making them an increasingly indispensable part of our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.