Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsional springs, often overlooked in the world of mechanical devices, play a crucial role in countless applications. These ingenious components harness the power of twisting force, acting like a coiled-up

Torsional springs, often overlooked in the world of mechanical devices, play a crucial role in countless applications. These ingenious components harness the power of twisting force, acting like a coiled-up energy reservoir ready to unleash a controlled rotation. From the delicate balance of a watch to the powerful torque of an automobile suspension, torsional springs quietly work their magic, ensuring smooth operation and precise movement. In this exploration, we'll delve into the fascinating world of torsional springs, uncovering their unique properties, diverse applications, and the science behind their remarkable twisting capabilities.

Imagine a spring not stretched or compressed, but twisted. That's the essence of a torsional spring. Unlike their extension and compression counterparts, torsional springs are designed to store and release energy through rotation. Their core function is to resist and generate twisting forces, acting like a coiled-up energy bank ready to unleash a controlled rotation. This twisting force, known as torque, is what makes torsional springs so versatile and indispensable in numerous mechanical systems.

The heart of a torsional spring lies in its carefully crafted helical shape. This spiral configuration allows it to efficiently absorb and release rotational energy. When a torsional spring is twisted, its internal structure resists this deformation, storing the applied energy as potential energy. As the twisting force is released, the spring unwinds, converting this stored energy back into rotational motion. This dynamic interplay of energy storage and release is what gives torsional springs their unique capabilities.

Torsional springs are silent heroes, quietly powering a vast array of applications across various industries. Their ability to deliver controlled rotational forces makes them indispensable in countless scenarios. Here are some key areas where torsional springs play a vital role:

1. Precision Instruments: Torsional springs are essential components in delicate instruments that demand precise control. In watches, for instance, a tiny torsional spring regulates the balance wheel's oscillation, ensuring accurate timekeeping. Similar precision is required in scientific instruments like galvanometers, where torsional springs ensure precise deflection of the needle in response to electrical currents.

2. Automotive Systems: From the smooth operation of steering wheels to the controlled movement of suspension systems, torsional springs are integral to automotive engineering. They provide the restoring force needed to return steering wheels to their neutral position and absorb shock loads in suspension systems, ensuring a comfortable and stable ride. Torsional springs are also found in other automotive components like door hinges and seat adjusters.

3. Industrial Machinery: Torsional springs play a crucial role in ensuring the smooth and precise operation of industrial machinery. In power tools, for example, they provide the spring action for clutches, allowing for controlled engagement and disengagement of the motor. They are also used in various other applications like conveyors, textile machinery, and machine tools, ensuring efficient and reliable performance.

4. Consumer Products: Torsional springs are not limited to industrial applications. They also find their way into everyday consumer products. The spring mechanism in retractable pens, for instance, uses a torsional spring to retract the writing tip. Similarly, torsional springs are employed in retractable cables on electronic devices, providing a smooth and controlled extension and retraction.

Several key factors influence the behavior and performance of a torsional spring, dictating its ability to store and release rotational energy. These factors are:

1. Material: The choice of material plays a crucial role in determining a torsional spring's strength, elasticity, and durability. High-strength steel alloys are often preferred for their excellent resilience and fatigue resistance, making them ideal for demanding applications. Other materials like phosphor bronze and beryllium copper are used where specific properties like corrosion resistance or electrical conductivity are required.

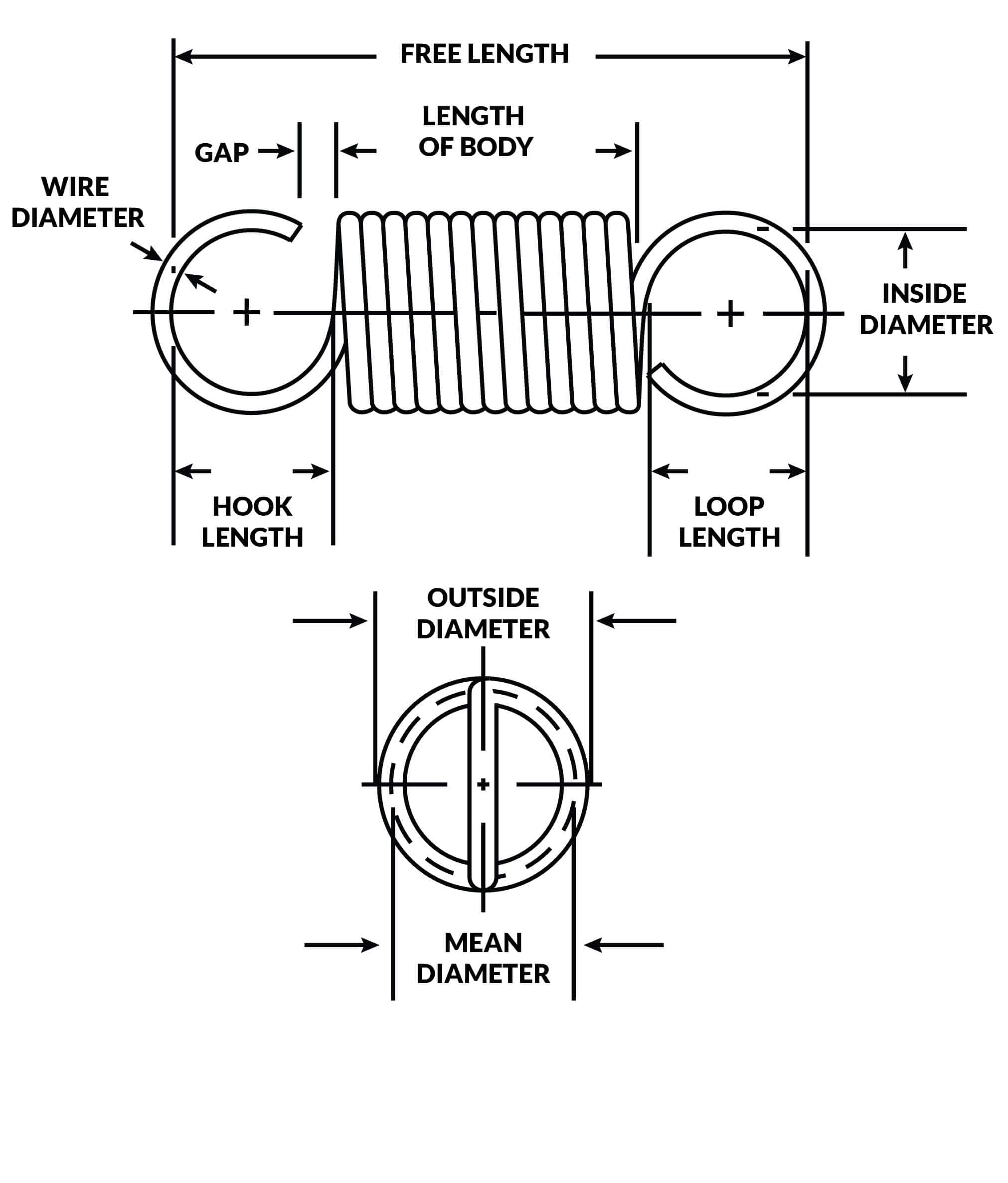

2. Wire Diameter: The diameter of the wire used to create the helical spring directly affects its stiffness and strength. A thicker wire will create a stiffer spring, requiring more torque to twist it. Conversely, a thinner wire will result in a more flexible spring, requiring less torque to achieve the same twist.

3. Coil Diameter: The diameter of the coil itself also influences the spring's stiffness. A larger coil diameter will create a more flexible spring, while a smaller coil diameter will result in a stiffer spring. The interplay between wire diameter and coil diameter is crucial in achieving the desired stiffness and torque characteristics.

4. Number of Coils: The number of coils in the spring directly impacts its stiffness. A larger number of coils increases the spring's overall length and flexibility. A smaller number of coils creates a shorter and stiffer spring. The number of coils is a key factor in determining the spring's overall range of motion and its ability to absorb energy.

While traditional helical torsional springs are widely used, there are specialized types designed for specific applications. These specialized torsional springs offer unique advantages and cater to demanding requirements:

1. Constant Force Torsional Springs: These innovative springs provide a nearly constant torque throughout their rotation, eliminating variations that can affect accuracy and performance. They are often used in applications where precise control is crucial, such as in precision instruments and mechanisms.

2. Variable Stiffness Torsional Springs: These springs allow for dynamic adjustment of their stiffness, adapting to changing loads and conditions. This flexibility is valuable in applications like shock absorbers, where the spring's stiffness needs to change based on the severity of the impact.

3. Torsional Springs with Multiple Coils: These springs incorporate multiple coils with varying diameters or wire thicknesses, creating a progressive stiffness profile. This allows for precise control of the spring's torque output, tailoring it to specific application requirements.

Torsional springs, though often unseen, are essential components in numerous mechanical systems, powering a wide array of applications with controlled rotational force. From delicate timepieces to powerful industrial machinery, they contribute to precise movement, efficient operation, and reliable performance. Understanding their unique properties and diverse applications opens a world of possibilities for harnessing the twisting power of these remarkable components.

The next time you encounter a device that rotates, swivels, or adjusts, consider the hidden force at play. There's a good chance a torsional spring is silently ensuring its smooth and precise operation. As we continue to innovate and develop new technologies, the role of torsional springs is likely to grow even more significant, making these twisting forces a crucial part of our mechanical future.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.