Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

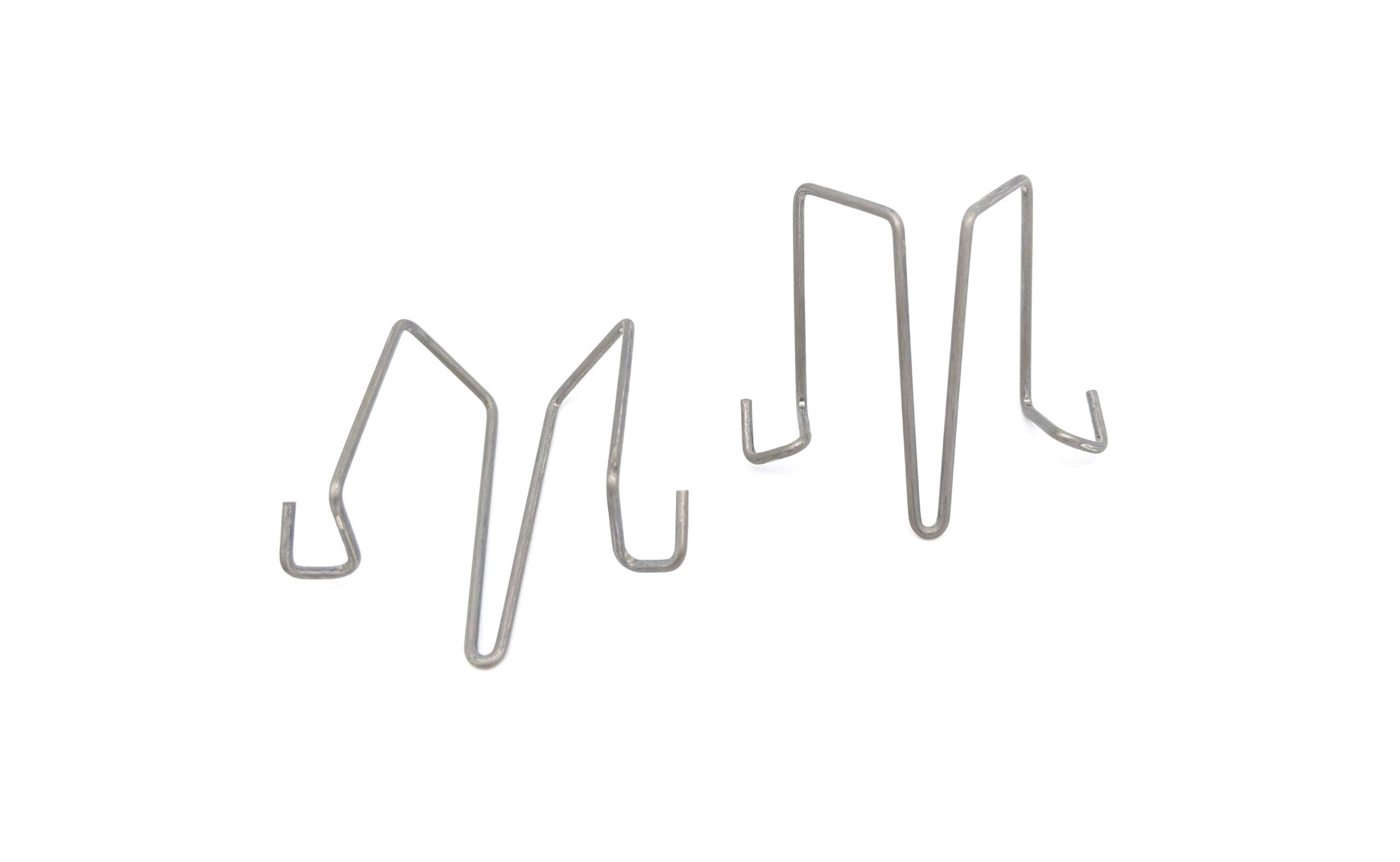

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsional springs, those coiled wonders of engineering, are often overlooked amidst the more familiar compression and tension springs. However, their unique ability to store and release energy through twisting motion

Torsional springs, those coiled wonders of engineering, are often overlooked amidst the more familiar compression and tension springs. However, their unique ability to store and release energy through twisting motion makes them indispensable components in a wide array of applications. From delicate mechanisms in watches to the robust systems powering vehicles, torsional springs are silently working behind the scenes, ensuring smooth operation and precise control. In this article, we delve into the fascinating world of torsional springs, exploring their design, principles, applications, and the impact they have on our everyday lives.

Imagine a spring not being compressed or stretched but rather twisted. That's the essence of a torsional spring! Unlike their linear counterparts, torsional springs are designed to store and release energy through rotational motion. They are essentially coiled wires or strips of elastic material that exert a restoring torque when twisted. This torque is proportional to the angle of twist, similar to Hooke's Law governing linear springs.

The core of a torsional spring's functionality lies in its ability to store energy when twisted and then release it as it returns to its original position. This makes them ideal for applications requiring controlled rotational movement, such as opening and closing mechanisms, tensioning devices, and providing precise feedback in various systems.

Torsional springs come in a variety of shapes and sizes, but their design principles are fairly consistent. Key factors determining the performance of a torsional spring include:

Torsional springs are ubiquitous in our world, contributing to the smooth operation of countless mechanisms. Here are some notable examples:

Selecting the right torsional spring for a specific application is crucial for optimal performance and longevity. Here are some key factors to consider:

Torsional spring technology continues to evolve, with new advancements emerging to meet the demands of increasingly complex and sophisticated applications. Some notable trends include:

From the intricate mechanisms of timepieces to the robust systems powering vehicles, torsional springs are silently working behind the scenes, ensuring smooth operation, precise control, and the efficient storage and release of energy. Their ability to store and release energy through twisting motion makes them indispensable components in a wide array of applications, contributing to the functionality and reliability of countless mechanical systems.

As technology continues to advance, torsional springs are likely to play an even greater role in the future, powering innovation and enhancing the capabilities of mechanical systems across various industries.

In conclusion, torsional springs are much more than just coiled metal. They are the embodiment of a fundamental principle in physics, cleverly designed to store and release energy through twisting motion. Their diverse applications, from the smallest mechanisms to the largest machines, highlight their importance in the modern world. As we continue to push the boundaries of technology, torsional springs are sure to remain essential components, driving innovation and shaping the future of mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.