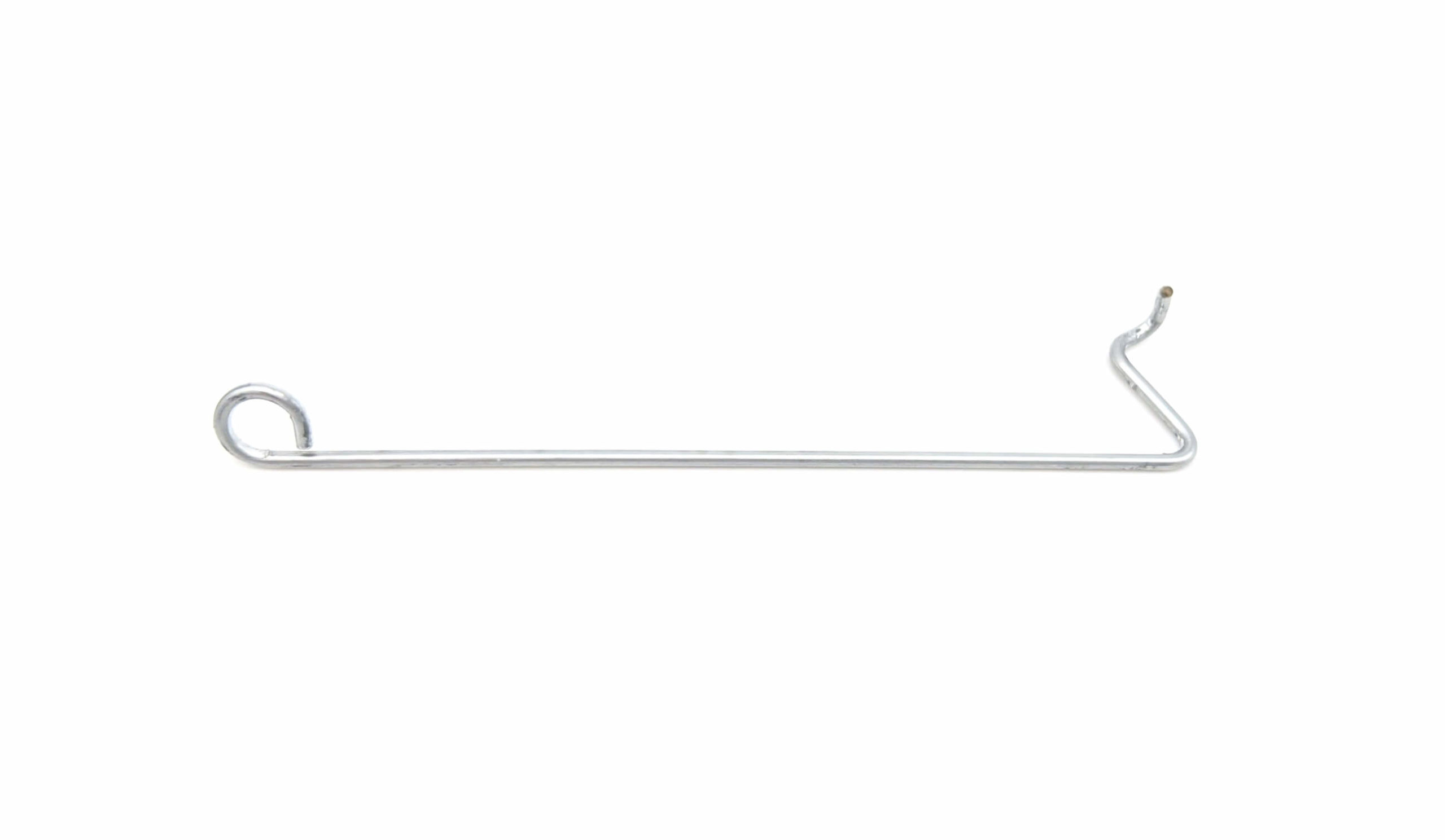

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a spring, but instead of being stretched or compressed, it twists. This is the essence of a torsional spring, a vital component in countless mechanical systems that harnesses rotational

Imagine a spring, but instead of being stretched or compressed, it twists. This is the essence of a torsional spring, a vital component in countless mechanical systems that harnesses rotational forces. Unlike their linear counterparts, torsional springs store energy by twisting, then release it to drive motion, power mechanisms, and provide precise control. From the intricate workings of clocks and watches to the robust mechanisms of automotive suspension systems, torsional springs play a silent, yet crucial role in our technological world.

Torsional springs, often called torsion springs, work by twisting. They are made of a resilient material, usually steel, which is coiled or shaped into a form that resists twisting. When a torque, or twisting force, is applied to the spring, it stores potential energy. As the spring twists, it builds up internal stress, ready to release that energy when the force is removed. The amount of force required to twist the spring, known as the spring rate, is a crucial parameter in designing systems that use torsional springs.

Torsional springs come in a variety of designs, each suited to different applications. Some common types include:

Torsional springs are ubiquitous in our modern world. Their ability to store and release rotational energy makes them indispensable in countless applications. Here are a few notable examples:

Torsional springs offer several advantages over other types of springs, making them ideal for a wide range of applications:

Designing a system with torsional springs requires careful consideration of several factors:

The world of torsional springs is constantly evolving, with advancements in materials and manufacturing processes leading to springs with improved performance, durability, and efficiency. New materials, such as high-strength alloys, are allowing for the creation of smaller, lighter springs with greater torque capacity. Advanced manufacturing techniques, such as laser cutting and 3D printing, are enabling the production of highly customized torsional springs with complex geometries. These innovations are expanding the horizons of what is possible with torsional springs, opening up new possibilities for a wider range of applications.

From the tiny mainspring in a watch to the robust torsion bars in a car, torsional springs are integral to a wide range of technologies that shape our world. Their ability to store and release rotational energy makes them invaluable for countless applications. As technology advances, we can expect to see even more innovative uses of torsional springs, pushing the boundaries of what is possible in mechanical design. So next time you see a spring, remember that even a simple coil can be a powerful force behind motion, precision, and control.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.