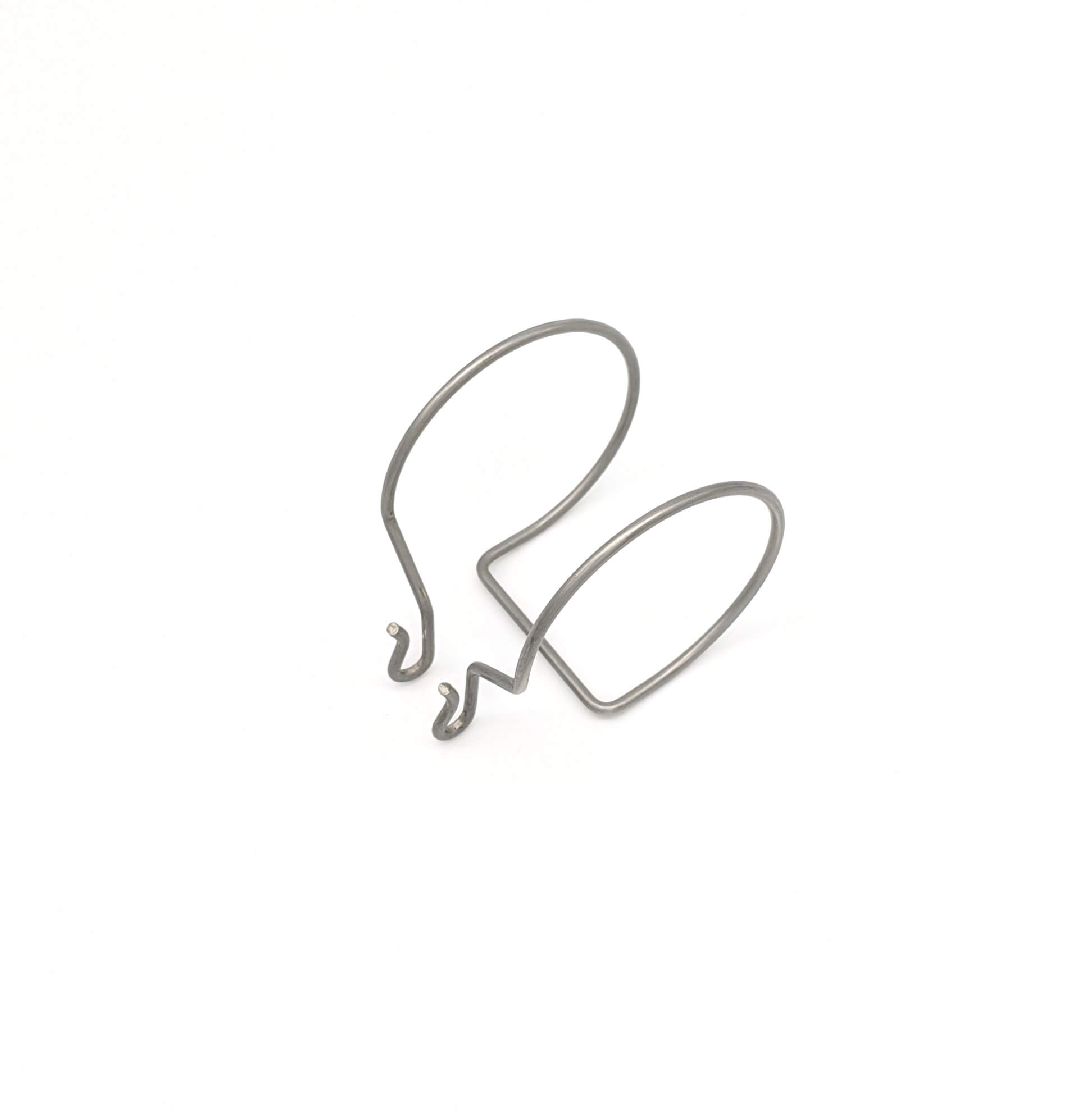

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of mechanics, springs and torsion bars are essential components that play crucial roles in a wide range of applications, from everyday objects to sophisticated machinery. While both

In the realm of mechanics, springs and torsion bars are essential components that play crucial roles in a wide range of applications, from everyday objects to sophisticated machinery. While both serve the purpose of storing and releasing energy, their unique mechanisms and applications set them apart. This article delves into the intricacies of torsion bars and springs, exploring their distinct characteristics, applications, and advantages and disadvantages.

Torsion, in simple terms, refers to the twisting or rotational force applied to an object. Imagine a rod fixed at one end and subjected to a force that attempts to rotate it around its axis. This force is known as a torsional force, and the resulting deformation is known as torsion. Torsion bars are specifically designed to withstand and respond to such twisting forces.

Torsion bars are essentially solid, cylindrical rods made from high-strength steel. They are typically used in vehicle suspensions, where they act as springs to absorb bumps and provide stability. When a wheel encounters an uneven road surface, the torsion bar twists, storing energy and then releasing it as the wheel returns to its normal position. This twisting action allows the torsion bar to provide a smooth ride while also ensuring the vehicle's stability.

Springs, on the other hand, are more commonly encountered in various applications. They are typically made from coiled wire and are designed to absorb and release energy in a linear direction. When a force is applied to a spring, it either compresses or extends, storing potential energy. Upon removal of the force, the spring returns to its original shape, releasing the stored energy.

Springs can be categorized into various types based on their design and functionality, including:

Springs are versatile components found in a wide range of applications, from everyday objects like pens and staplers to complex machinery and automotive systems.

While torsion bars and springs share the common function of storing and releasing energy, they differ significantly in their mechanisms and applications. Here's a closer look at the key differences:

| Feature | Torsion Bar | Spring |

|---|---|---|

| Mechanism | Twisting or rotational force | Linear compression or extension |

| Material | Solid steel rod | Coiled wire |

| Applications | Vehicle suspensions, suspension systems | Mechanical devices, automotive systems, everyday objects |

| Advantages | High strength, durable, stable, compact | Versatile, customizable, easy to manufacture |

| Disadvantages | Limited adjustability, complex installation | Less durable, potential fatigue, may require more space |

The choice between a torsion bar and a spring ultimately depends on the specific requirements of the application. For applications that demand high strength, durability, and stability, such as vehicle suspensions, torsion bars are a preferred choice. Conversely, for applications requiring versatility, easy manufacturing, and adaptability, springs are often a better option.

Torsion bars and springs are indispensable elements in the world of mechanics. They represent distinct approaches to storing and releasing energy, each with its own advantages and drawbacks. By understanding their fundamental differences and applications, engineers can choose the most suitable component to meet the specific demands of their designs. From the smooth ride of a vehicle to the intricate mechanisms of a clock, these two forces of force and motion continue to shape our world, making it a more functional and dynamic place.

In essence, torsion bars and springs, while different in their mechanisms, serve the common purpose of providing elasticity and resilience. Their distinct characteristics make them valuable components in a myriad of applications, from everyday objects to complex machinery. Ultimately, the choice between torsion and spring hinges on the specific requirements of the application, and understanding their unique capabilities is crucial for engineers and designers to create efficient and reliable systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.