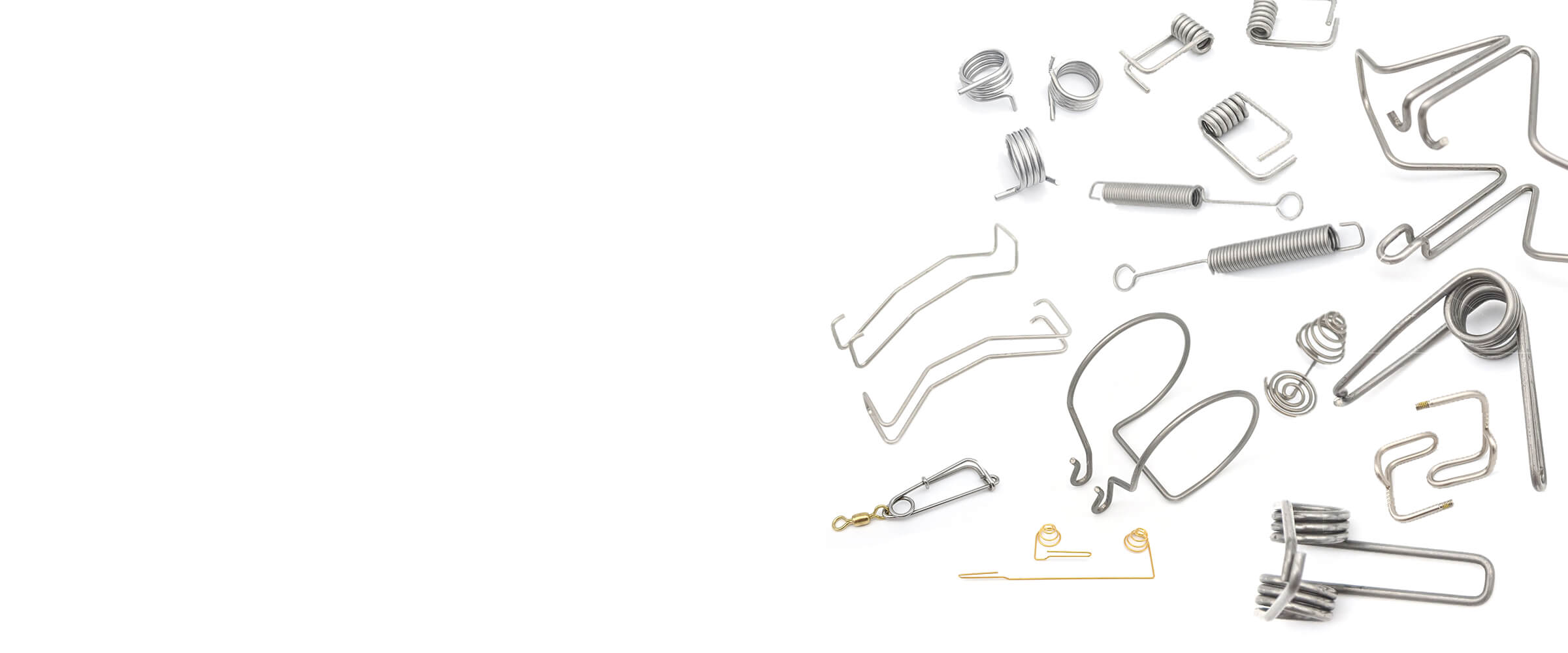

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of mechanical engineering, springs play a crucial role in a wide array of applications. From the delicate balance of a watch to the robust suspension of a

In the realm of mechanical engineering, springs play a crucial role in a wide array of applications. From the delicate balance of a watch to the robust suspension of a vehicle, springs provide the necessary elasticity and resilience to maintain functionality. Among the diverse types of springs, torsion and tension springs stand out as two distinct categories, each with its unique characteristics and applications. While both types store and release energy, they do so through different mechanisms and exhibit different behaviors. This article delves into the fascinating world of torsion and tension springs, shedding light on their fundamental differences, key applications, and the factors that guide their selection for specific engineering projects.

Imagine a spring that's designed to twist rather than compress or extend. That's precisely what a torsion spring does. These springs are marvels of engineering, utilizing the principle of torque to store and release energy. When a twisting force is applied to a torsion spring, it resists the rotation and stores energy. This stored energy is then released as the spring attempts to return to its original, untwisted state. Think of a spring-loaded door closer or a retractable clothesline – these are prime examples of torsion springs in action.

Tension springs are designed to be pulled, stretched, or extended. They're often used to maintain tension or provide a restoring force. Imagine a spring used to hold a window open or a garage door closed. When you apply a force to stretch the spring, it stores energy. As you release the force, the spring contracts, returning to its original length and releasing the stored energy. Tension springs find widespread applications in everything from simple mechanisms like clothes pegs to more complex machinery like automotive suspension systems.

The fundamental difference between torsion and tension springs lies in the direction of the force they exert. Torsion springs respond to twisting forces, while tension springs react to pulling forces. Here's a breakdown of their key distinctions:

• Torsion springs: Resist twisting forces, generating torque.

• Tension springs: Resist pulling forces, generating tension.

• Torsion springs: Typically coiled or helical, with ends designed for rotation.

• Tension springs: Also coiled, often with hooks or loops at their ends for attachment.

• Torsion springs: Widely used in door closers, garage door openers, retractable clotheslines, and spring-loaded mechanisms.

• Tension springs: Find applications in windows, springs, garage door springs, and mechanical devices requiring tension.

Choosing the right type of spring for a particular application involves careful consideration of several factors. The specific design requirements, operating environment, and desired spring behavior will all influence the decision:

• If your application involves twisting or rotational forces, a torsion spring is the way to go.

• If your application requires a pulling or stretching force, a tension spring is the better option.

The force required for the spring to perform its function will determine the spring's strength and stiffness.

The surrounding temperature, humidity, and corrosive substances can impact spring performance. Selecting materials that are compatible with the operating environment is crucial.

The available space for the spring will dictate its size and shape.

Torsion and tension springs are readily available in various sizes and materials. However, cost can be a significant factor, especially for high-volume applications.

While torsion and tension springs represent the fundamental categories, engineering innovation has expanded the range of spring types to meet the diverse needs of modern technology.

• **Variable Rate Springs:** These springs are designed with a changing stiffness, allowing for greater control and adaptability in complex applications.

• **Constant Force Springs:** As the name suggests, these springs maintain a nearly constant force as they extend or retract, making them ideal for applications requiring consistent tension.

Understanding the differences between torsion and tension springs is essential for any engineer or designer working with mechanical systems. While their basic functionalities differ, both types play crucial roles in countless applications. Selecting the right spring for a specific project involves careful consideration of the load type, operating environment, and desired spring behavior.

From the precise movements of a watch to the robust strength of a vehicle's suspension, springs are the unsung heroes of modern technology. By mastering the fundamentals of torsion and tension springs, engineers and designers can harness their unique capabilities to create innovative and reliable solutions.

As we have explored, understanding the differences between torsion and tension springs is crucial for anyone involved in designing or selecting mechanical systems. The choice between these two types hinges on a variety of factors, including the type of force needed, the operating environment, and specific design considerations. By carefully evaluating these factors, engineers can make informed decisions that ensure optimal performance, reliability, and functionality for any given application.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.