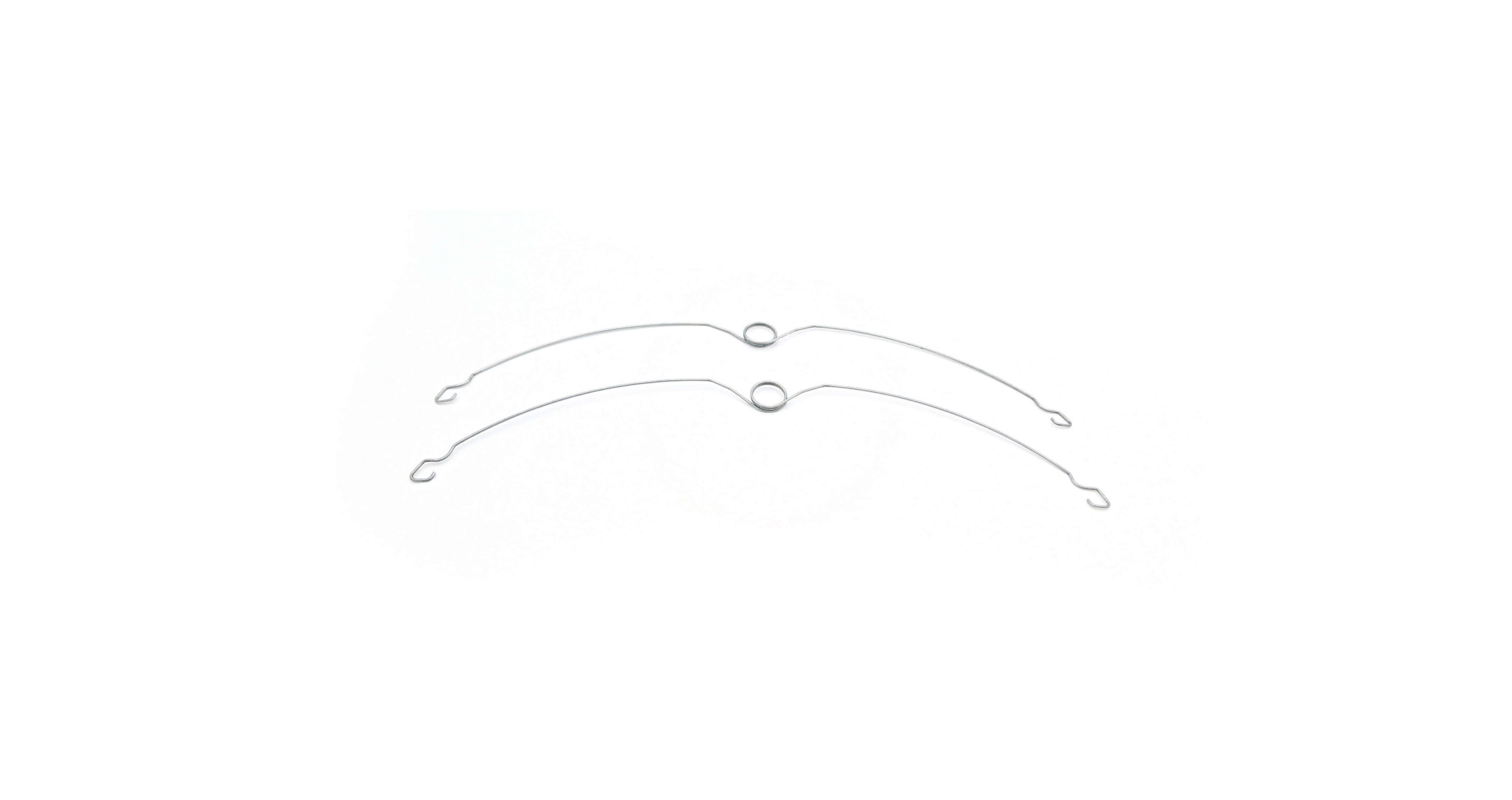

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Choosing the right spring for your application can be a daunting task, especially when you have to decide between torsion and compression springs. Both types offer unique advantages and disadvantages,

Choosing the right spring for your application can be a daunting task, especially when you have to decide between torsion and compression springs. Both types offer unique advantages and disadvantages, making it crucial to understand their characteristics and applications. This article delves into the world of springs, comparing and contrasting torsion and compression springs to help you make an informed decision for your specific needs.

Torsion springs are coiled springs designed to store and release energy by twisting or rotating. They are typically made of wire wound into a helix, with the ends fixed to a shaft or frame. When a force is applied to the spring's shaft, it twists, storing energy within the coil. As the force is removed, the spring returns to its original position, releasing the stored energy.

Torsion springs find their applications in a wide range of industries, including:

Compression springs, as the name suggests, are designed to resist compression forces. These springs are typically made of coiled wire that compresses when a load is applied. The spring pushes back against the load, restoring its original length when the force is removed.

Compression springs are commonly used in a variety of applications, including:

While both torsion and compression springs store and release energy, they differ significantly in their design and applications.

1. Force Application: Torsion springs operate by twisting or rotating, while compression springs operate by compressing or shortening.

2. Energy Storage: Torsion springs store energy in the form of torsional strain, while compression springs store energy in the form of compressional strain.

3. Deflection: Torsion springs deflect by twisting, while compression springs deflect by shortening.

4. Force-Deflection Relationship: The force-deflection relationship is linear for compression springs but often non-linear for torsion springs.

5. Applications: Torsion springs are ideal for applications requiring rotational motion, while compression springs are suitable for applications requiring linear motion.

Advantages:

Disadvantages:

Advantages:

Disadvantages:

The choice between a torsion and compression spring ultimately depends on the specific requirements of your application. Consider these factors:

1. Force and Deflection Needs: What force and deflection are required for your application?

2. Space Constraints: How much space is available for the spring?

3. Application Environment: What are the temperature, humidity, and load conditions?

4. Operating Frequency: How frequently will the spring be cycled?

5. Cost and Material Considerations: What is the budget for the spring, and what materials are suitable for the application?

Torsion and compression springs both play crucial roles in various industries, each offering unique strengths and weaknesses. By understanding their characteristics, advantages, and disadvantages, you can make an informed decision about which spring type best suits your application. Ultimately, the right spring is the one that meets your specific requirements and delivers optimal performance.

Choosing the right spring is essential for ensuring optimal performance and reliability. This article has provided a comprehensive comparison of torsion and compression springs, highlighting their key differences, advantages, and disadvantages. By carefully considering the factors discussed, you can select the spring type that best meets your application's needs and achieve a successful outcome.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.