Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a spring that stores energy by twisting, not stretching. That's the essence of a torsion spring, a vital component in countless mechanisms, from the simple act of opening a

Imagine a spring that stores energy by twisting, not stretching. That's the essence of a torsion spring, a vital component in countless mechanisms, from the simple act of opening a door to the complex workings of a watch. Though often hidden from view, these coiled marvels are the unsung heroes of motion and precision, silently driving countless everyday objects. This article delves into the fascinating world of torsion springs, exploring their design, functionality, and diverse applications in various fields.

Unlike the familiar compression or extension springs, torsion springs work on the principle of rotation. They are essentially coiled wires or bars designed to store energy when twisted, releasing it to produce a rotational force. This unique characteristic makes them ideal for applications requiring controlled movement, precise force, and compact design.

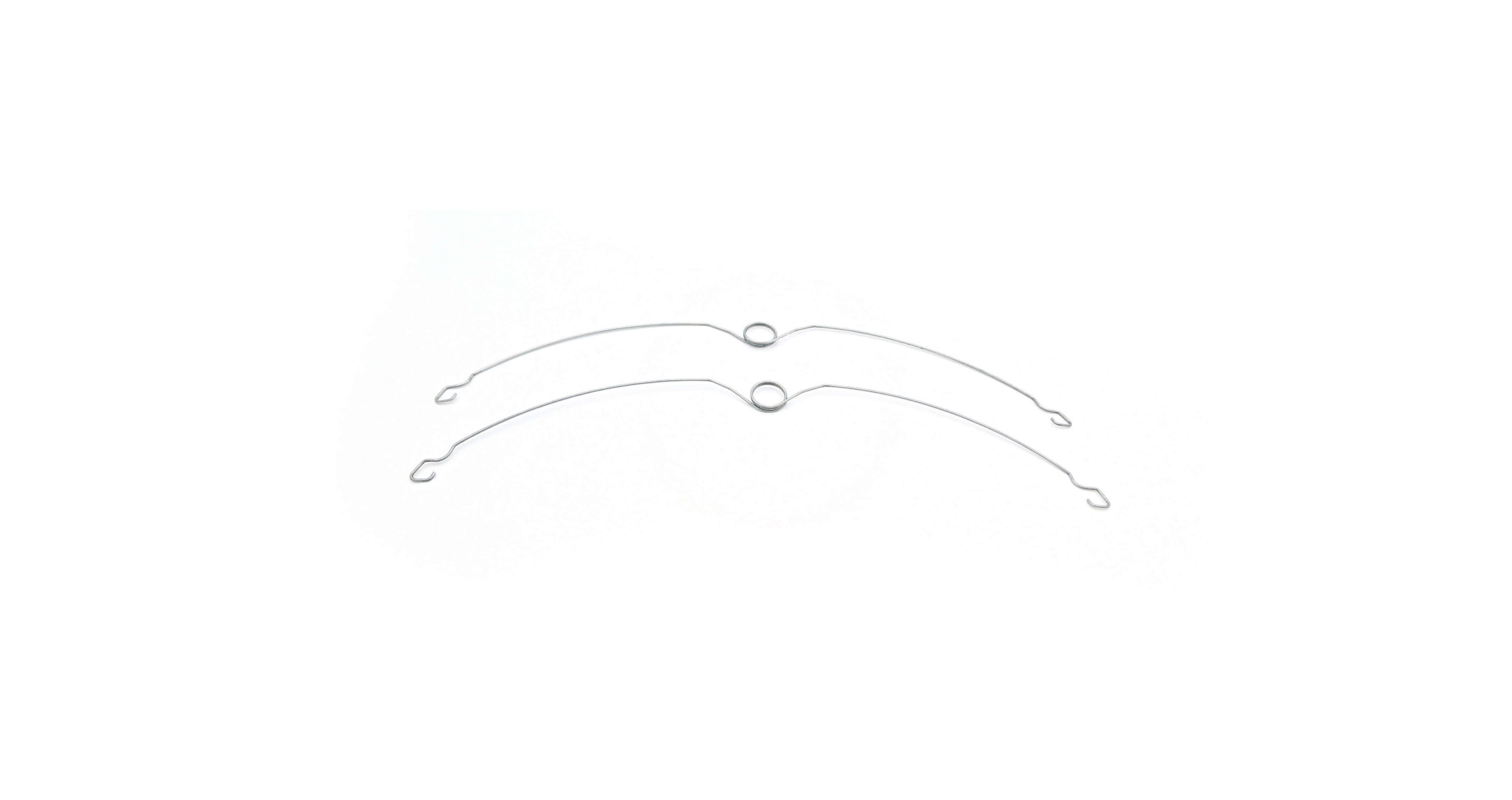

The simplest torsion spring is a single coil of wire, with one end fixed and the other free to rotate. When a force is applied to the free end, the spring twists, storing energy in its elastic deformation. Upon release, this stored energy drives the spring back to its original position, creating a rotational motion. However, many applications involve more complex torsion springs, featuring multiple coils and varying geometries to achieve specific force and motion profiles.

The material used in a torsion spring significantly influences its performance. Steel is the most common choice due to its strength, resilience, and affordability. However, depending on the application, other materials like stainless steel (for corrosion resistance), phosphor bronze (for high conductivity), or even exotic alloys (for extreme temperature or load requirements) may be employed. The choice of material is a crucial design aspect, as it directly impacts the spring's load capacity, fatigue life, and overall performance.

Torsion springs are ubiquitous, quietly powering our world in countless ways. Here are a few examples:

Choosing the right torsion spring is crucial for optimal performance. Factors to consider include:

Torsion spring technology continues to evolve, leading to more sophisticated designs and applications. For instance, variable rate torsion springs provide varying degrees of stiffness throughout their rotation, allowing for more nuanced control and force management. Furthermore, composite materials and specialized coatings are being explored to enhance durability, corrosion resistance, and even biocompatibility for medical applications.

Torsion springs, though often unseen, are the backbone of countless mechanisms, delivering precise and reliable motion across a vast array of applications. Their ability to store and release rotational energy makes them essential for everything from door closers to intricate clockwork mechanisms. As technology continues to evolve, so too will the applications and designs of torsion springs, ensuring their continued importance in driving the world around us.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.