Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without smooth, controlled movements. Doors slamming shut, car windows rattling, and even the simple act of opening a drawer becoming a struggle. This is the reality without

Imagine a world without smooth, controlled movements. Doors slamming shut, car windows rattling, and even the simple act of opening a drawer becoming a struggle. This is the reality without torsion springs, the unsung heroes of motion that power countless everyday objects. These coil-shaped marvels, often overlooked but always at work, play a crucial role in ensuring our world operates smoothly and efficiently.

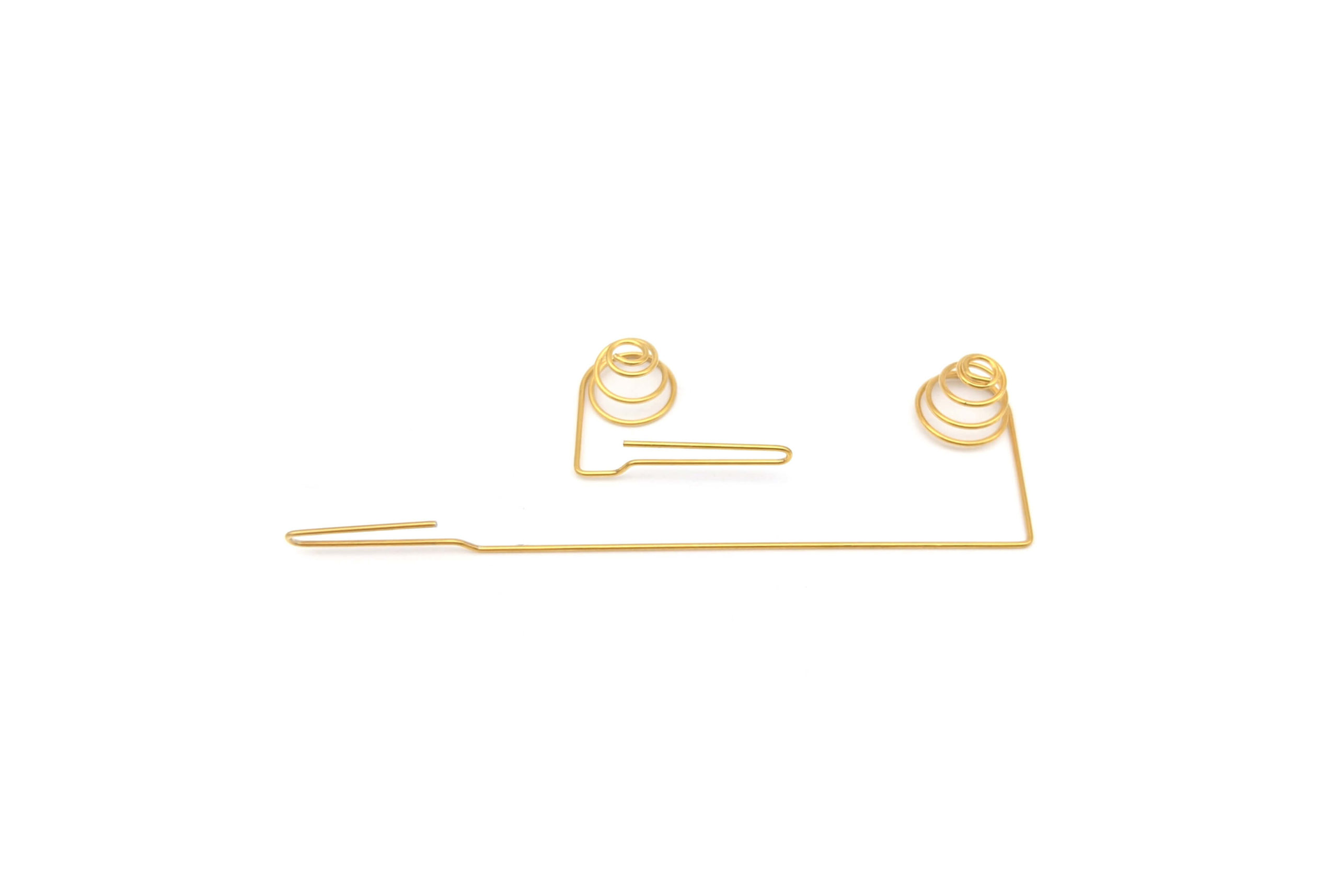

Torsion springs, as the name suggests, store and release energy by twisting. They are made of coiled metal wire, typically steel, that are designed to resist twisting forces. When a force is applied, the spring coils up, storing energy like a compressed spring. Upon release, this stored energy is transformed into rotational motion, driving a mechanism or returning an object to its original position.

The beauty of torsion springs lies in their versatility. They can be customized in size, shape, and material to suit a wide range of applications, making them adaptable to various engineering challenges. Imagine a tiny torsion spring powering the delicate mechanism of a watch, or a robust one working tirelessly within the door hinges of a heavy industrial machinery.

Torsion springs are broadly classified into two main types:

Beyond these core types, there are numerous variations within each category, each tailored for specific applications. For example, some torsion springs are designed for constant force, while others provide variable force depending on the angle of twist.

Torsion springs are truly ubiquitous. They are integral components in a vast array of products and systems, from everyday household items to sophisticated industrial machinery.

Torsion springs silently work their magic in our homes and offices:

Beyond our homes, torsion springs play a crucial role in various industries:

The widespread adoption of torsion springs is not simply a matter of coincidence. They offer several advantages that make them ideal for a wide range of applications:

With such a wide range of applications and variations, selecting the right torsion spring for your needs can feel daunting. However, by understanding the key factors involved, you can make an informed choice:

Consulting with a torsion spring specialist or manufacturer can be invaluable in selecting the optimal spring for your application.

Torsion springs are often the invisible force behind smooth, controlled motion in our everyday lives. Their versatility, reliability, and cost-effectiveness have made them indispensable in a vast array of applications. From the subtle movements of a watch to the heavy-duty operations of industrial machinery, these unassuming coils play a vital role in shaping our world.

So, the next time you open a door, pull out a drawer, or witness the smooth operation of a complex machine, remember the unseen heroes at work – the torsion springs that ensure effortless motion and a world that runs smoothly.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.