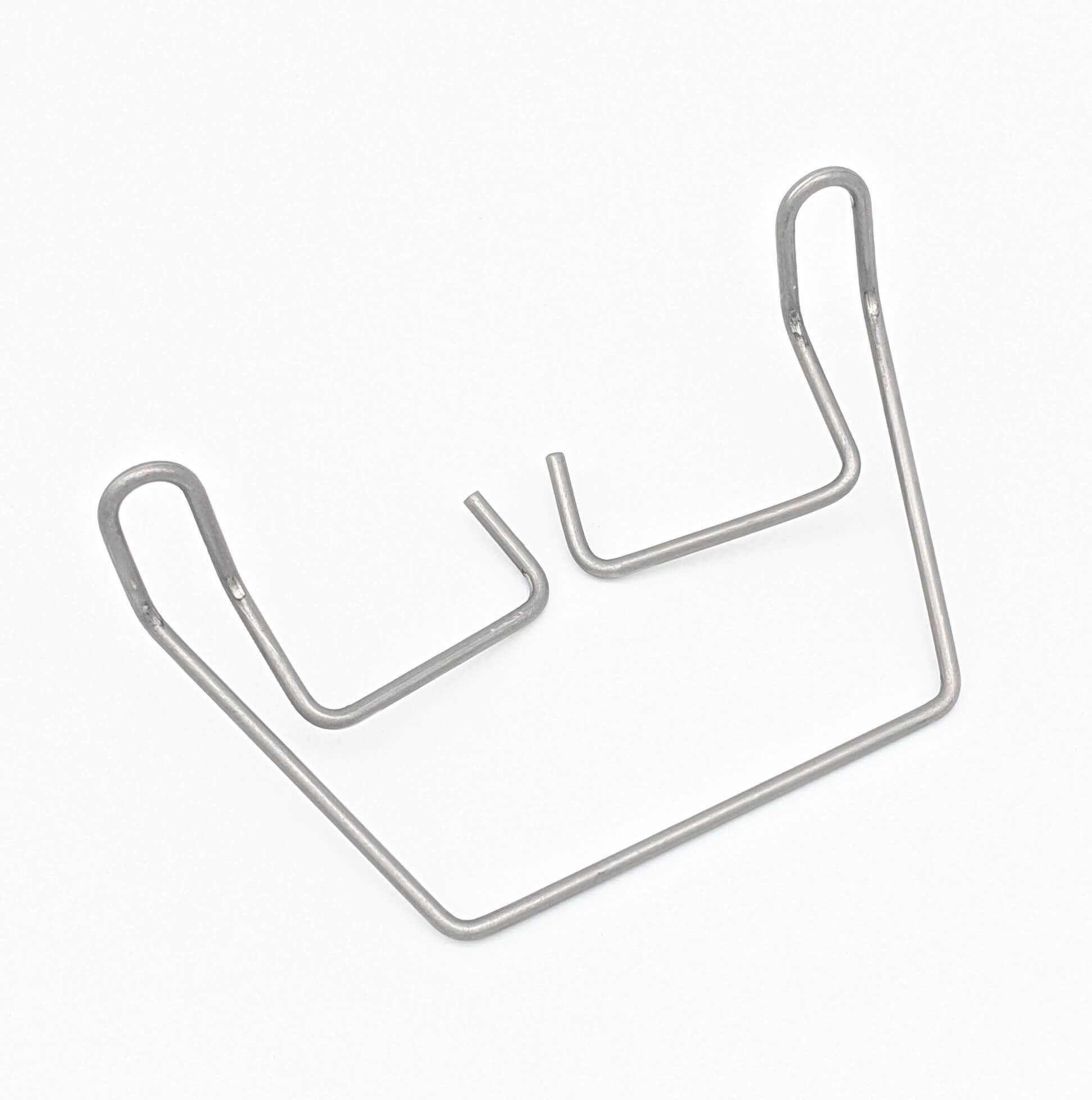

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, often overlooked yet essential, play a critical role in countless mechanical devices we encounter daily. These coiled wonders, operating under twisting forces, provide a unique form of energy

Torsion springs, often overlooked yet essential, play a critical role in countless mechanical devices we encounter daily. These coiled wonders, operating under twisting forces, provide a unique form of energy storage and release, enabling a wide range of functionalities, from simple clothespins to complex automotive components. This article delves into the world of torsion springs, exploring their working principles, diverse applications, and the factors influencing their design and selection.

Unlike compression or extension springs that react to linear forces, torsion springs operate under twisting or rotational force, also known as torque. When you apply torque to a torsion spring, you're essentially winding or unwinding it, causing it to store potential energy. This stored energy is then released in the opposite direction, generating a rotational force. Imagine a tightly wound rubber band; as you twist it further, it builds up tension, and when released, it unwinds forcefully. Torsion springs work in a similar fashion, albeit with greater precision and control.

A typical torsion spring consists of a coiled wire or rod, crafted from materials like stainless steel, music wire, or hard-drawn spring wire. The ends of the spring, known as 'legs', are designed to interface with other mechanical components. These legs are crucial as they dictate how the spring mounts and transmits torque. You'll find various leg configurations, each tailored for specific applications, such as straight legs, hooked legs, short hook legs, hinged legs, and more. This diversity allows engineers to integrate torsion springs seamlessly into a wide array of mechanisms.

The versatility of torsion springs makes them indispensable across numerous industries. You'll encounter them in everyday objects like clothespins and safety pins, where they provide the necessary clamping force. In more complex applications, torsion springs are pivotal in automotive components like hinges and suspension systems. They're also crucial in door hinges, ensuring smooth opening and closing, and in agricultural machinery, enabling efficient operation of various implements. The electronics industry relies on torsion springs for sensitive components like switches and relays, highlighting their precision and reliability.

Choosing the right torsion spring involves careful consideration of several factors. The intended application dictates the required torque and deflection characteristics. The environment in which the spring operates, including temperature and humidity, influences material selection. Factors like wire diameter, coil diameter, and leg configuration directly impact the spring's performance. Precision is paramount; factors like spring rate (the amount of torque required for a specific rotation) and fatigue life (the number of cycles the spring can withstand) are critical for ensuring long-term reliability.

As engineering demands evolve, torsion springs are continuously being refined and optimized. Advanced materials and manufacturing techniques are pushing the boundaries of their performance. Miniaturization trends are driving the development of micro-torsion springs for applications in micro-mechanics and biomedical devices. With ongoing research and development, we can expect to see torsion springs playing an increasingly crucial role in emerging technologies, further solidifying their place as unsung heroes in the world of mechanical engineering.

Torsion springs, despite their unassuming nature, are essential components in a vast array of mechanical devices. Their ability to store and release energy through twisting forces enables a multitude of functionalities, making them indispensable in various industries. As we advance technologically, the demand for precision, reliability, and miniaturization will drive further innovation in the field of torsion springs, ensuring they continue to play a critical role in shaping the future of mechanical engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.