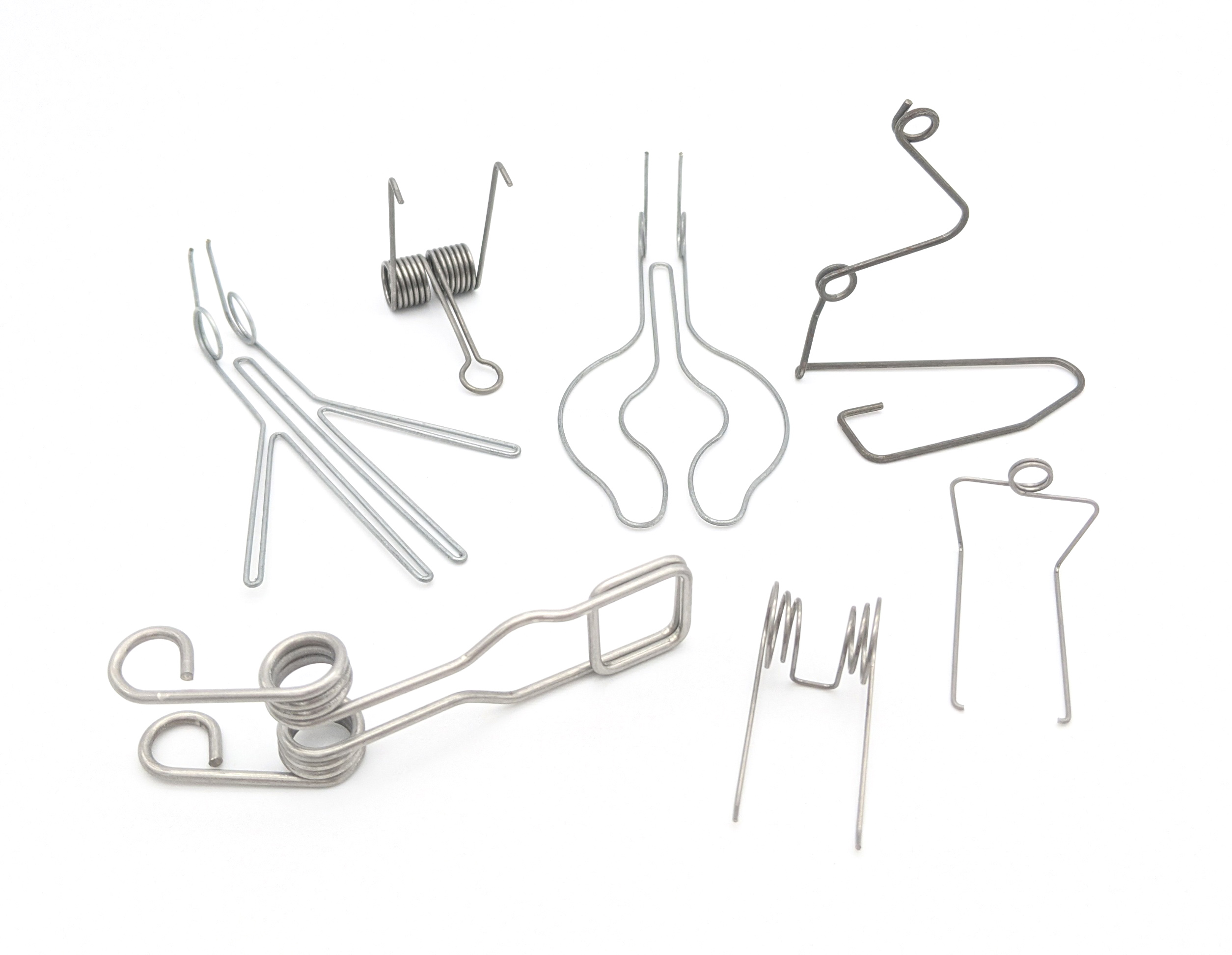

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, those often overlooked components of mechanical systems, play a crucial role in countless applications. From the delicate balance of a watch to the powerful action of a car's

Torsion springs, those often overlooked components of mechanical systems, play a crucial role in countless applications. From the delicate balance of a watch to the powerful action of a car's suspension, torsion springs provide a reliable and efficient way to store and release rotational energy. This article delves into the world of torsion springs, exploring their unique characteristics, diverse applications, and the principles behind their operation.

Unlike their linear counterparts, compression and extension springs, torsion springs are designed to resist twisting forces, or torque. They're essentially elastic elements that store and release energy through rotation. Imagine a tightly wound ribbon – that's the basic principle of a torsion spring. When you twist one end of the ribbon, it stores energy, and when you release it, the ribbon unwinds, releasing that stored energy.

The heart of a torsion spring is its coiled wire, usually made of high-strength materials like spring steel. This wire, when subjected to a twisting force, experiences a change in its shape. The material's inherent elasticity allows it to store the applied torque as potential energy. When the force is removed, the spring's coiled structure seeks to return to its original shape, releasing the stored energy.

The amount of torque a torsion spring can store and release depends on several factors, including the wire's diameter, the number of coils, and the material's properties. The relationship between the applied torque and the resulting angular rotation is often linear within a specific range, known as the spring's working range. This linear relationship makes torsion springs predictable and reliable in their performance.

Torsion springs come in a variety of configurations to suit diverse needs. Common types include:

Torsion springs are ubiquitous in everyday life, playing vital roles in various applications:

Torsion springs offer a number of advantages that make them ideal for many applications:

Designing a torsion spring involves careful consideration of several factors, including:

Torsion springs, often working behind the scenes, are critical components that contribute to the smooth and reliable operation of countless mechanical systems. Their ability to store and release rotational energy in a predictable and efficient manner makes them indispensable for a wide range of applications. Understanding the principles behind torsion springs and their diverse applications allows engineers and designers to harness their power and innovation to create efficient and reliable products.

From the simple act of retracting a tape measure to the complex engineering of aircraft control surfaces, torsion springs demonstrate the incredible versatility and power of simple mechanical design principles. By embracing their unique capabilities, engineers and designers can continue to push the boundaries of innovation and efficiency in the world of mechanical systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.