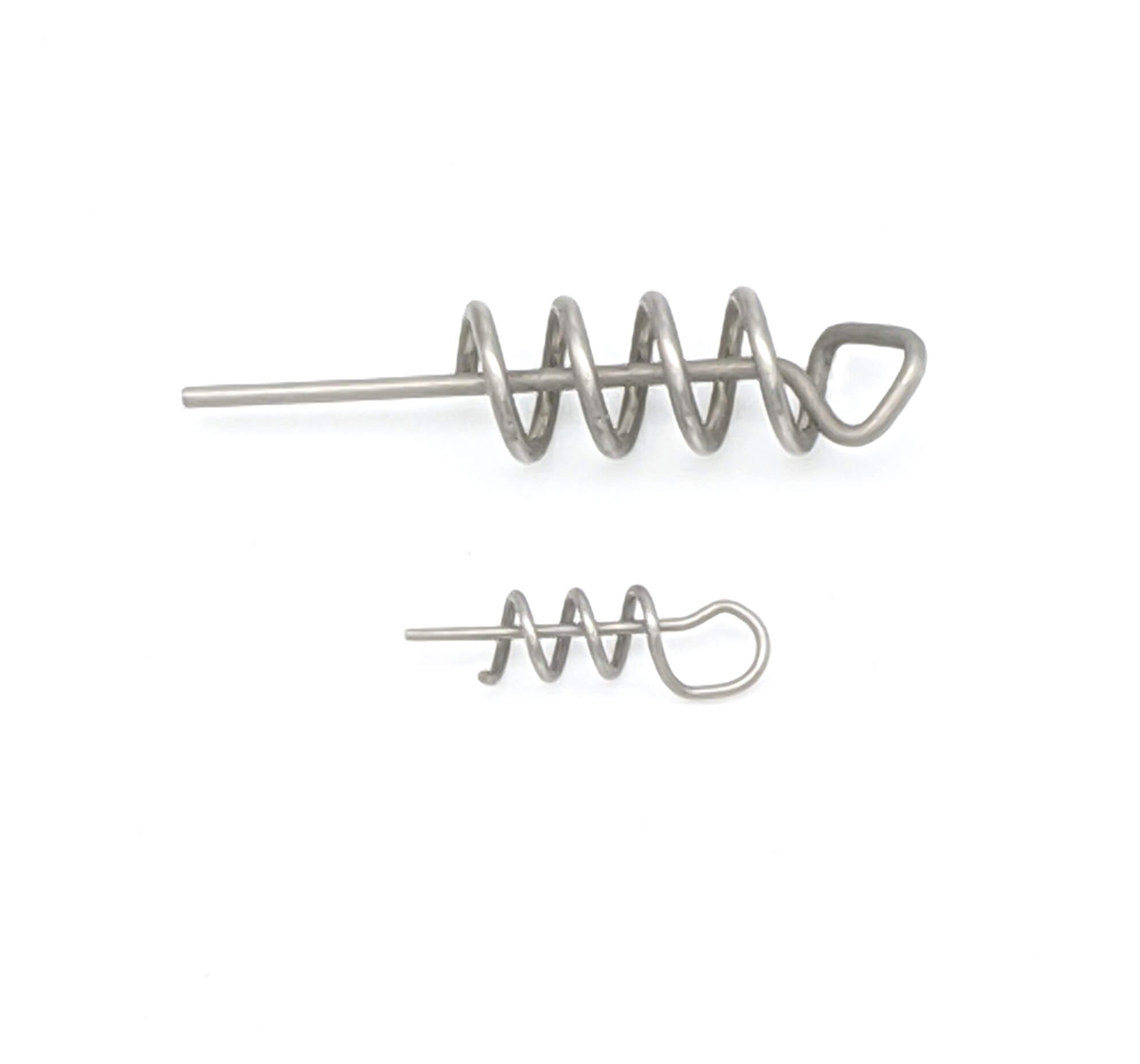

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without door hinges, garage doors, or even the satisfying click of a ballpoint pen. These seemingly simple mechanisms rely on a crucial component – the torsion spring.

Imagine a world without door hinges, garage doors, or even the satisfying click of a ballpoint pen. These seemingly simple mechanisms rely on a crucial component – the torsion spring. These coiled marvels, often unseen and unappreciated, are the workhorses of countless applications, providing the force and resilience needed to power everyday motions. From the intricate workings of clocks to the robust functionality of heavy machinery, torsion springs play a vital role, quietly ensuring smooth, reliable operation.

Torsion springs, as their name suggests, store and release energy through twisting or rotation. They are typically made of high-quality spring steel, carefully coiled into a helical shape. The unique design allows the spring to accumulate potential energy when twisted and then release this energy in a controlled manner, propelling the connected mechanism. Unlike compression or extension springs, which exert force along a linear axis, torsion springs exert torque, or rotational force, around their axis.

The beauty of torsion springs lies in their versatility. They can be tailored to deliver specific force levels, operating within varying degrees of rotation. This customization is achieved through careful control of factors like spring wire diameter, coil diameter, number of coils, and the type of spring steel used. These parameters are meticulously determined during design to ensure the spring delivers the desired performance and durability.

The applications of torsion springs are as diverse as the world around us. They power the smooth opening and closing of doors, garage doors, and windows, providing a vital safety feature and a comfortable user experience. They play a critical role in the intricate mechanisms of clocks, providing the consistent force needed for accurate timekeeping. Torsion springs can be found in virtually any device that requires rotational motion, including retractable pens, automotive components, medical equipment, and even toys.

In the realm of industrial applications, torsion springs are indispensable. They are integral parts of heavy machinery, providing the robust force needed for lifting, clamping, and other demanding operations. Their resilience and reliability make them ideal for use in environments where high-stress and frequent cycling are the norm. In manufacturing processes, torsion springs ensure precise movement and control, contributing to efficient and consistent production.

The design of a torsion spring is crucial for its proper functionality. Key factors include:

When designing a torsion spring, engineers meticulously consider these factors to optimize its performance for the intended application. The spring rate, which describes the relationship between the applied torque and the resulting rotation, is a critical parameter. A higher spring rate indicates a stiffer spring that requires more torque to rotate, while a lower spring rate indicates a more flexible spring that can be rotated with less force.

The longevity and reliability of torsion springs are crucial in many applications. Factors like the quality of spring steel, manufacturing tolerances, and proper heat treatment all play a role in ensuring the spring's performance over time. A well-designed and manufactured torsion spring will resist fatigue and wear, ensuring smooth operation and a long service life.

To maintain the quality and longevity of torsion springs, proper maintenance is essential. Regular inspection and lubrication can help prevent premature wear and tear, ensuring the spring continues to perform at its best. In applications where the spring is subjected to harsh environments or extreme loads, it's even more critical to implement proactive maintenance practices.

Torsion springs, despite their often unseen nature, are essential components in a vast array of applications. They provide the force, resilience, and precision needed for smooth, reliable operation, contributing to the functionality of everything from everyday objects to complex machinery. Their versatility and durability make them invaluable in industries ranging from manufacturing and automotive to medical and consumer goods.

As technology continues to evolve, torsion springs will likely play an even more prominent role in the future. Their ability to store and release energy in a controlled manner will be crucial in developing innovative solutions for a wide range of applications. From tiny micro-springs used in advanced electronics to large-scale power systems, torsion springs will continue to be the unsung heroes of mechanics, quietly ensuring the smooth and efficient operation of the world around us.

The next time you open a door, admire the smooth movement of a clock hand, or marvel at the power of a machine, remember the unsung hero working behind the scenes – the torsion spring. These simple, coiled marvels play a vital role in our world, making it a more functional and efficient place. Their versatility, resilience, and quiet dedication ensure the smooth operation of countless everyday objects and complex machinery, solidifying their place as the unsung heroes of mechanics.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.