Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of precision engineering, where tolerances are measured in microns and the tiniest imperfections can have significant consequences, every component plays a vital role. Torsion spring winding rods,

In the world of precision engineering, where tolerances are measured in microns and the tiniest imperfections can have significant consequences, every component plays a vital role. Torsion spring winding rods, though often overlooked, are essential tools in the manufacturing of these intricate springs. These rods, with their unique design and capabilities, are the backbone of the process, ensuring the precise coiling and shaping of torsion springs that power countless devices.

Torsion springs are unique in the world of spring design, relying on the twisting force applied to their axis rather than compression or extension. This twisting action makes them ideal for a wide variety of applications, including:

The accuracy and consistency of torsion spring winding are crucial to their functionality. A slight error in the winding process can significantly impact the spring's performance, leading to decreased lifespan, inconsistent tension, or even failure. This is where torsion spring winding rods shine.

Torsion spring winding rods are specialized tools designed specifically for the production of torsion springs. They are typically made from high-quality steel or other durable materials, ensuring strength and resistance to wear and tear during the winding process. These rods are designed to hold the spring wire in place as it is twisted around a central mandrel, creating the spiral shape of the torsion spring.

The rods themselves can come in various sizes and configurations, depending on the specific requirements of the spring being produced. Some rods may feature grooves or other specialized features to aid in the winding process, ensuring that the coils of the spring are evenly spaced and tightly wound.

Winding a torsion spring isn't as simple as it may seem. It involves a delicate balance of forces and angles. The winding rod must be manipulated with precision to ensure that the wire is coiled consistently and without any kinks or bends.

The process often involves specialized winding machines, which use automated mechanisms to control the winding rod's movement. These machines allow for precise control of the spring's dimensions and shape, ensuring that each spring meets the demanding specifications. However, even with advanced machinery, the skill of the operator is paramount. They must carefully monitor the winding process, adjusting the machine's settings as needed to achieve the desired results.

There are several key benefits to using torsion spring winding rods in the manufacturing process:

Torsion spring winding rods are essential tools in the manufacture of a wide array of products, from the cars we drive to the devices we rely on in our daily lives. Their contribution may go unnoticed, but they play a vital role in ensuring that these springs function as intended. Their precision, durability, and efficiency make them indispensable components in the world of precision engineering.

In a world driven by precision and innovation, the seemingly simple torsion spring winding rod deserves a place of honor. These unassuming tools are instrumental in the creation of components that power countless industries, proving that even the smallest details can have the biggest impact. As technology continues to advance, the demand for high-quality torsion springs will only increase, further solidifying the importance of these essential tools in the world of manufacturing.

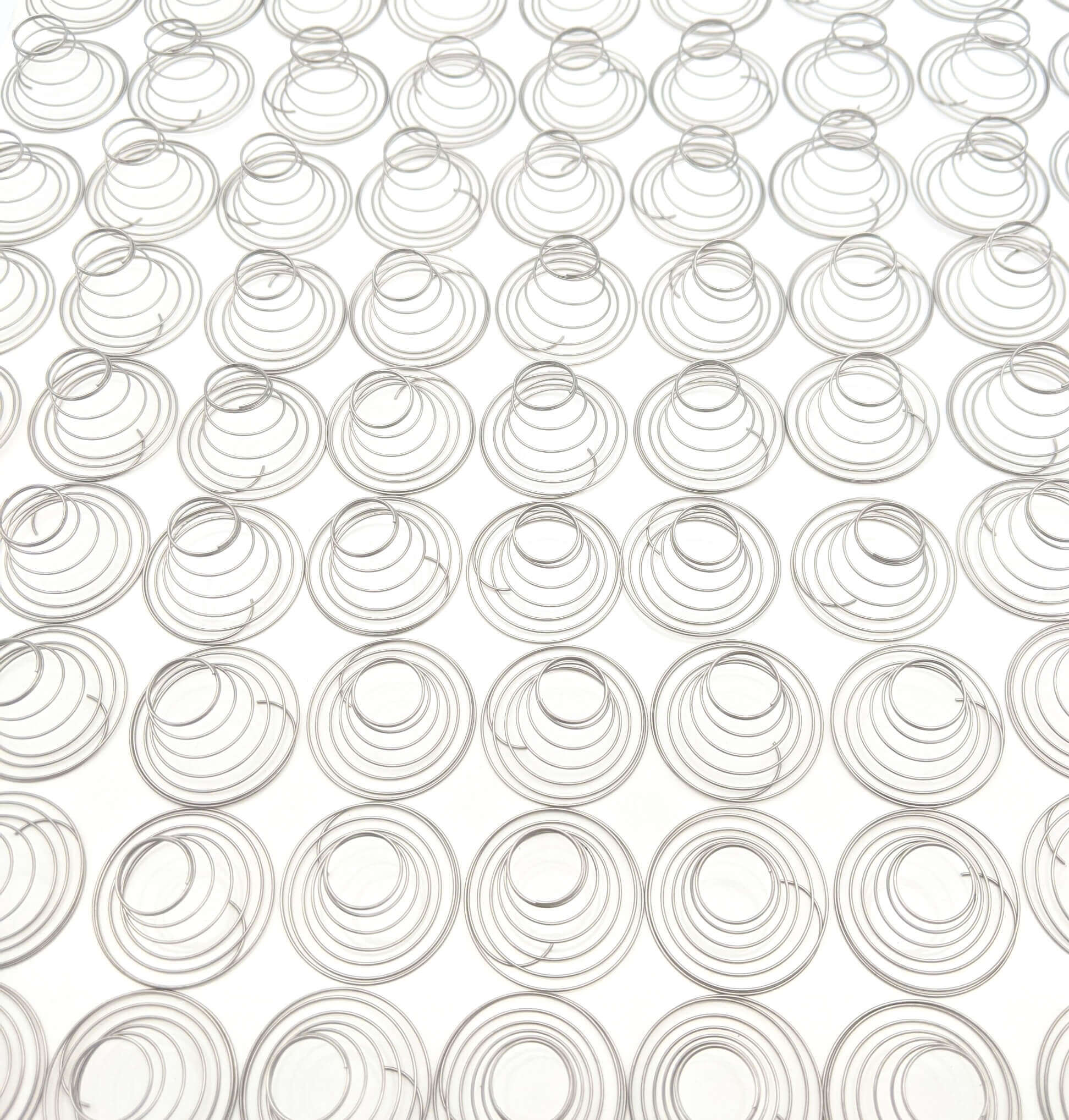

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.