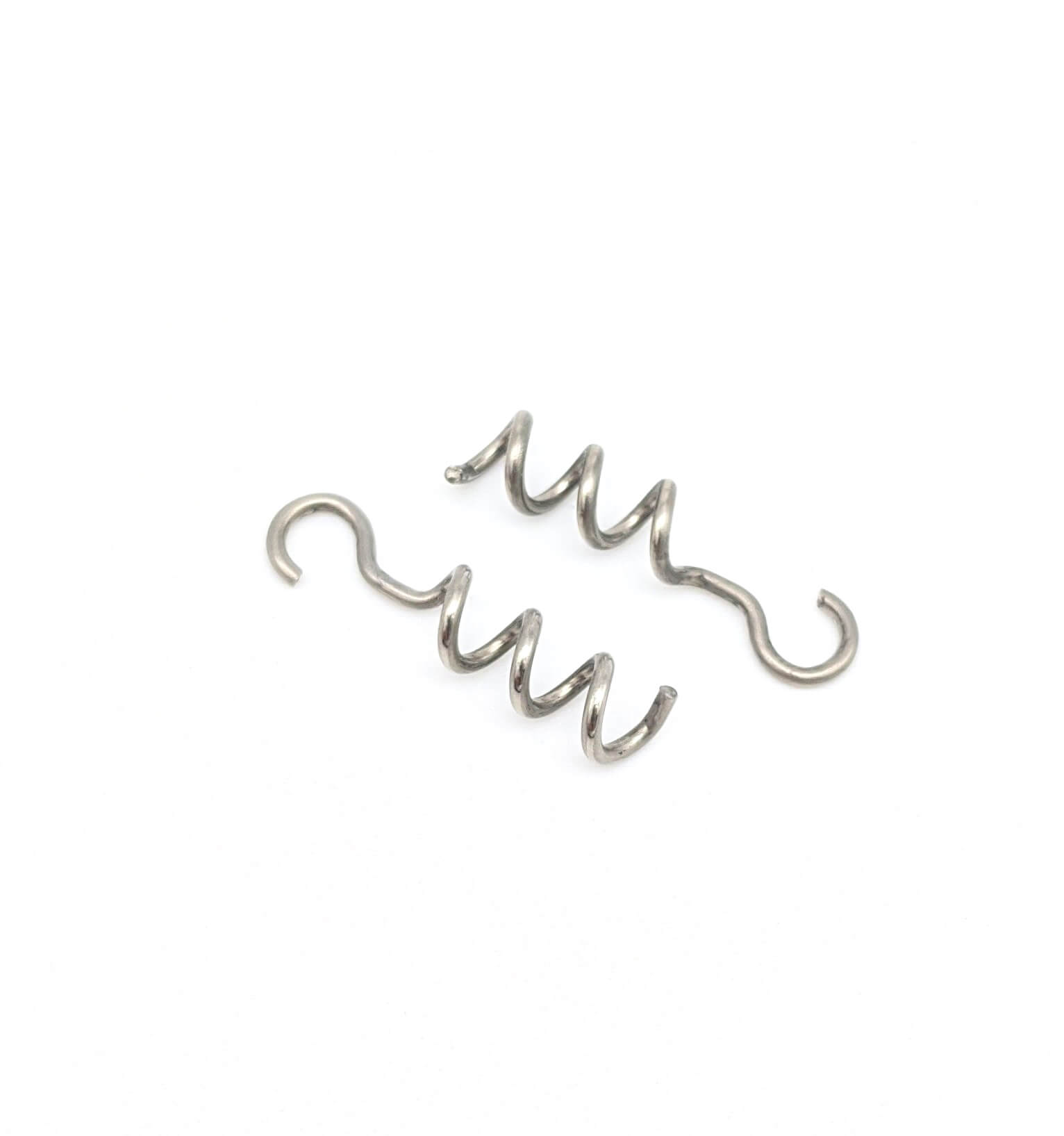

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion spring winding rods, often overlooked yet critically important, are the unseen heroes in the creation of high-quality torsion springs. These seemingly simple rods play a vital role in the

Torsion spring winding rods, often overlooked yet critically important, are the unseen heroes in the creation of high-quality torsion springs. These seemingly simple rods play a vital role in the winding process, directly impacting the spring's final performance, reliability, and overall quality. Understanding their function and the key factors that influence their selection is essential for achieving optimal spring design and production.

Torsion springs are marvels of engineering, designed to store and release rotational energy. They are ubiquitous in various applications, from everyday objects like retractable pens to intricate machinery in manufacturing. But how are these springs made? Enter the unsung heroes: torsion spring winding rods.

These rods are the heart of the winding process, responsible for precisely coiling the spring wire around a mandrel. The winding rod, typically made of hardened steel, guides the wire with unwavering accuracy, ensuring that each turn is tightly wound and consistent. This precision is paramount because any deviation in winding can lead to inconsistencies in the spring's characteristics, ultimately affecting its performance.

Selecting the right winding rod is a crucial step in achieving the desired spring characteristics. Several key factors must be considered:

1. Rod Diameter: The diameter of the winding rod directly influences the spring's outside diameter (OD) and wire diameter. A larger rod will result in a larger OD and allow for thicker wire to be wound. The specific choice of rod diameter depends on the spring's intended application and required load capacity.

2. Rod Material: Hardened steel is the standard material for winding rods, chosen for its durability and ability to withstand the forces involved in winding. However, other materials like tungsten carbide may be used for special applications that require even greater wear resistance.

3. Rod Surface Finish: A smooth and polished rod surface is essential to prevent wire damage and ensure consistent winding. Rough surfaces can create friction points and lead to irregularities in the spring's coil.

4. Rod Length: The length of the winding rod determines the maximum length of the spring that can be wound. This is particularly important for long-travel springs used in demanding applications.

5. Rod Taper: Some winding rods are tapered to facilitate the removal of the finished spring. The taper allows the spring to slide off the rod more easily without causing damage.

The quality and characteristics of the winding rod directly influence the performance of the finished torsion spring. Here's how:

1. Spring Stiffness: The winding rod's diameter directly affects the spring's stiffness. A larger rod will generally produce a less stiff spring, while a smaller rod will create a stiffer spring. This is due to the change in the effective spring diameter.

2. Spring Fatigue Life: Consistent and precise winding reduces stress concentrations in the spring wire, contributing to a longer fatigue life. A poorly wound spring can have stress concentrations that lead to premature failure.

3. Spring Consistency: A properly selected and maintained winding rod ensures that each spring produced is consistent in its characteristics, reducing variability and ensuring reliable performance.

With the constant advancement in manufacturing technology, innovations are constantly shaping the world of torsion spring winding rods. Some of these trends include:

1. Automated Winding Systems: Automated winding systems are becoming increasingly prevalent, offering enhanced precision and efficiency. These systems often employ specialized winding rods designed for specific applications.

2. Advanced Materials: Research is exploring the use of advanced materials for winding rods, aiming to improve wear resistance, reduce friction, and enhance overall performance.

3. Sustainable Manufacturing Practices: The focus on sustainability in manufacturing is driving the use of eco-friendly materials and processes in the production of winding rods.

Torsion spring winding rods are essential components that play a crucial role in the production of high-quality, reliable torsion springs. By carefully selecting and maintaining winding rods, manufacturers can ensure that their springs meet stringent performance requirements. As technology continues to advance, innovations in winding rods will undoubtedly continue to shape the future of spring design and manufacturing.

The next time you encounter a torsion spring, remember the vital role that the winding rod played in its creation. It's a testament to the importance of seemingly simple components in the world of precision engineering. The winding rod ensures the spring's strength, resilience, and consistent performance, making it an indispensable part of the spring production process.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.