Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, those coiled marvels of metal, play a crucial role in countless mechanical devices, providing the essential force for everything from clamping and tensioning to opening and closing. But

Torsion springs, those coiled marvels of metal, play a crucial role in countless mechanical devices, providing the essential force for everything from clamping and tensioning to opening and closing. But behind the reliable performance of a torsion spring lies a critical component: the torsion spring winding bar. These seemingly simple tools are, in fact, the backbone of torsion spring production, wielding precision and strength to craft these vital components.

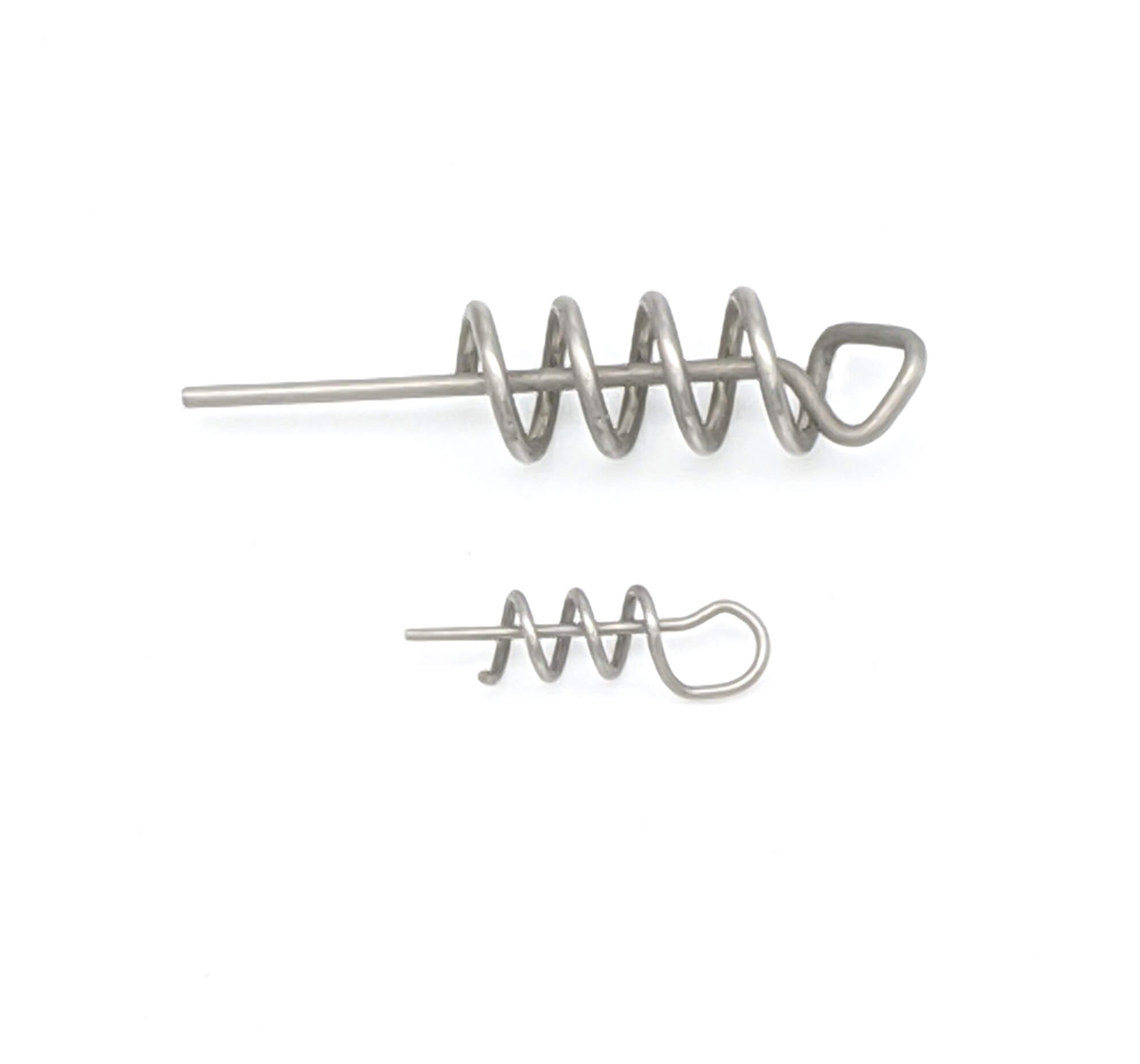

A torsion spring winding bar is a specialized tool employed in the manufacturing of torsion springs. It's a rod-like device with a specific shape and material, designed to precisely wind the spring wire around itself. This process creates the helical coil that forms the basis of a torsion spring. Without a robust and well-crafted winding bar, producing springs with consistent quality and reliability would be a monumental task.

The primary function of a torsion spring winding bar is to provide a controlled environment for the winding process. It's crucial to ensure the wire is wound tightly and evenly, without any kinks or imperfections. A well-designed winding bar will ensure that the spring maintains its desired shape and elasticity, crucial for its intended application.

Torsion spring winding bars come in a variety of shapes and sizes, tailored to different applications and spring designs. Common types include:

The type of winding bar used depends on the desired spring characteristics, such as size, stiffness, and shape. Each bar is designed to produce a specific type of spring, ensuring consistent quality and performance.

Torsion spring winding bars are typically made from high-strength materials, such as hardened steel or alloys. This ensures that they can withstand the stresses and strains involved in the winding process. The material also needs to be resistant to wear and tear, as winding bars are subjected to significant friction during use.

The construction of a winding bar is also critical. They often feature a precision-machined surface to ensure smooth and consistent winding. The diameter of the winding bar is crucial, as it dictates the size of the spring coils. Any imperfections or deviations in the winding bar can lead to inconsistencies in the spring's shape and performance.

The quality of a torsion spring is directly linked to the precision and craftsmanship of the winding bar. A high-quality winding bar ensures that the spring is wound evenly and tightly, minimizing the risk of kinks, imperfections, or stress points. These factors can significantly impact the spring's lifespan and performance.

Here are some ways a winding bar impacts spring quality:

In short, the winding bar is not simply a tool; it's a critical factor in achieving the desired performance and longevity of a torsion spring.

Like any precision tool, torsion spring winding bars require proper maintenance to ensure their continued effectiveness. Regular cleaning and lubrication are essential to prevent wear and tear, ensuring that the bar remains smooth and efficient. Any damage or wear to the winding bar should be addressed promptly to avoid compromising spring quality.

With advancements in manufacturing technology, torsion spring winding bars are evolving. Automated systems, incorporating precision robotics and advanced control systems, are increasingly being employed for winding springs. These systems offer greater accuracy, speed, and repeatability, enhancing the overall efficiency and quality of spring production.

However, even with these advancements, the core principles of winding bar design and functionality remain vital. The quest for producing consistent and reliable torsion springs continues, and the winding bar will undoubtedly play a pivotal role in achieving this goal.

In conclusion, torsion spring winding bars are crucial tools in the manufacturing of these essential mechanical components. Their role in ensuring spring quality, consistency, and longevity cannot be overstated. As technology advances, the winding bar will continue to evolve, but its fundamental importance in the production of torsion springs will remain a cornerstone of precision engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.