Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

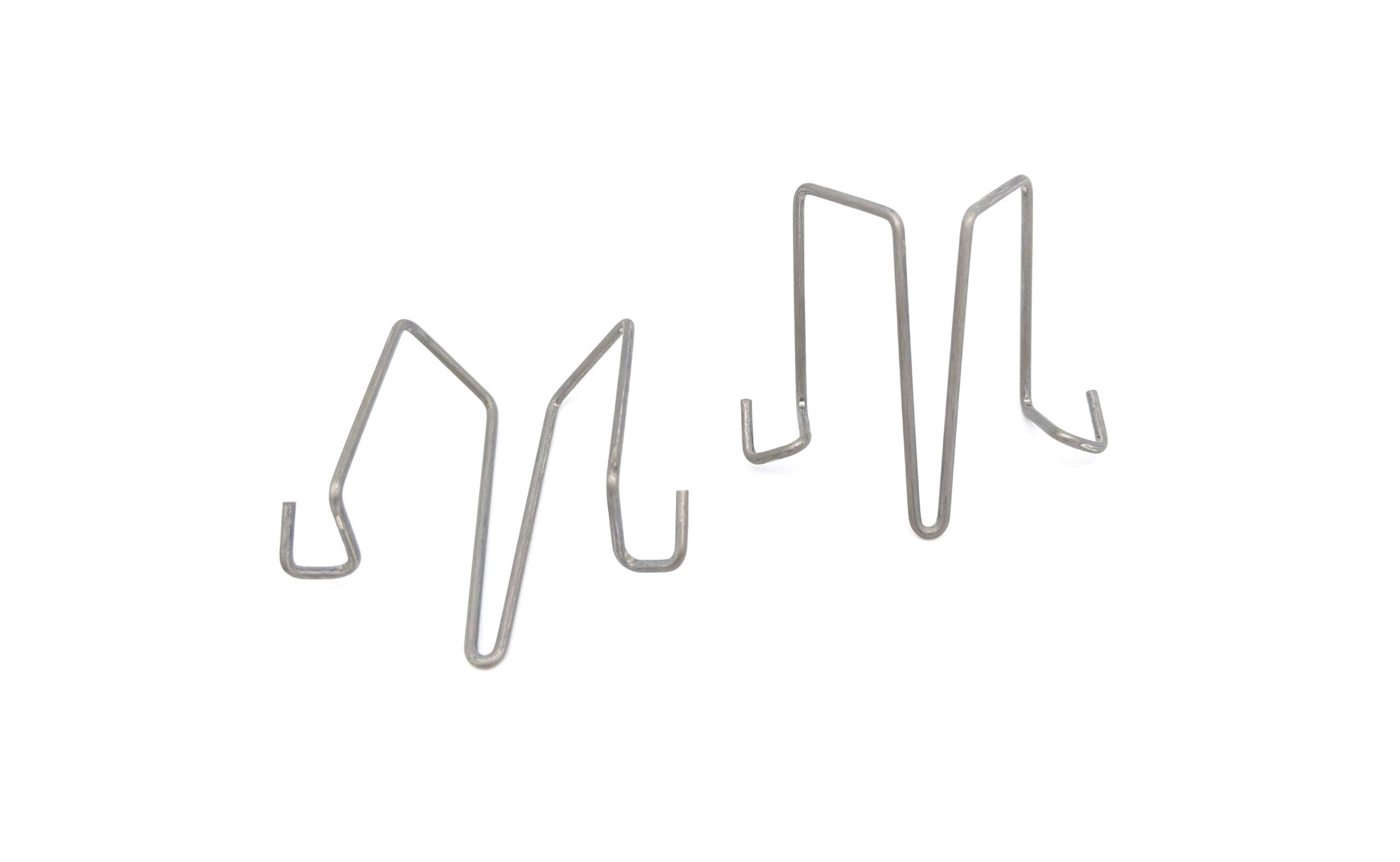

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanics and engineering, springs play a crucial role in countless applications, from everyday objects like door hinges to complex machinery. These seemingly simple devices come in

In the world of mechanics and engineering, springs play a crucial role in countless applications, from everyday objects like door hinges to complex machinery. These seemingly simple devices come in various forms, each designed to perform specific functions. Two of the most common types are torsion springs and tension springs. While they both work by storing and releasing energy, they differ significantly in how they do so. This article delves into the key distinctions between torsion springs and tension springs, exploring their unique properties, applications, and advantages. By understanding these differences, you can make informed decisions when selecting the right spring for your specific needs.

Imagine a spring that twists rather than stretches or compresses. This is the essence of a torsion spring. It's designed to store and release energy through rotational motion. Think of a car's suspension system where torsion bars act as torsion springs. When the car encounters a bump, the torsion bar twists, absorbing the impact and storing the energy. As the car settles back down, the torsion bar untwists, releasing the stored energy.

Torsion springs work by twisting about their axis. When a torque is applied to one end, the spring twists, storing energy. The amount of twist, known as the angle of deflection, is proportional to the applied torque. When the torque is removed, the spring tries to return to its original, untwisted state, releasing the stored energy. This process can be likened to winding up a rubber band and then letting it unwind.

Torsion springs find widespread use in various industries, including:

Tension springs, in contrast to torsion springs, operate in a linear fashion. They are designed to stretch or extend when a force is applied, storing energy in the process. Think of the spring inside a retractable ballpoint pen; when you pull on it, the spring stretches, and when you release it, the spring retracts, pushing the pen tip back into the housing.

Tension springs work by resisting an applied tensile force. When you pull on a tension spring, it stretches, storing energy. This energy is stored in the stretched material itself. When the force is released, the spring tries to return to its original, unstretched state, releasing the stored energy. The more you stretch a tension spring, the more energy it stores.

Tension springs are ubiquitous in numerous applications, such as:

The fundamental difference lies in the way they store and release energy. Torsion springs work by twisting, while tension springs work by stretching. Here's a more detailed comparison:

| Feature | Torsion Spring | Tension Spring |

|---|---|---|

| Loading Mechanism | Torque or twisting force | Tensile force or pulling force |

| Deflection | Rotational angle | Linear distance |

| Applications | Suspension systems, door hinges, power tools | Retractable pens, seatbelt mechanisms, spring-loaded toys |

| Shape | Typically coiled or helical | Can be coiled or flat |

| Advantages | Efficient at storing rotational energy, compact design | Easy to manufacture, versatile in applications |

| Disadvantages | Can be complex to design and manufacture | Limited force capacity compared to some torsion springs |

The choice between a torsion spring and a tension spring depends on the specific requirements of your application. Consider the following factors:

Torsion springs and tension springs are two fundamental types of springs that play crucial roles in a wide range of applications. Understanding their differences and advantages is essential for selecting the appropriate spring for your specific needs. Whether you're designing a complex piece of machinery or simply replacing a worn-out spring in a door hinge, this knowledge will help you make informed decisions and ensure that your project runs smoothly.

In conclusion, torsion springs and tension springs are distinct but equally valuable components in various mechanical systems. While torsion springs excel in managing rotational forces, tension springs are adept at dealing with linear forces. Their applications range from everyday objects to sophisticated machinery. When choosing between the two, it's crucial to consider the type of motion required, the force requirements, space constraints, and environmental conditions. By understanding these factors, you can select the right spring for your specific needs, optimizing the performance and reliability of your project.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.