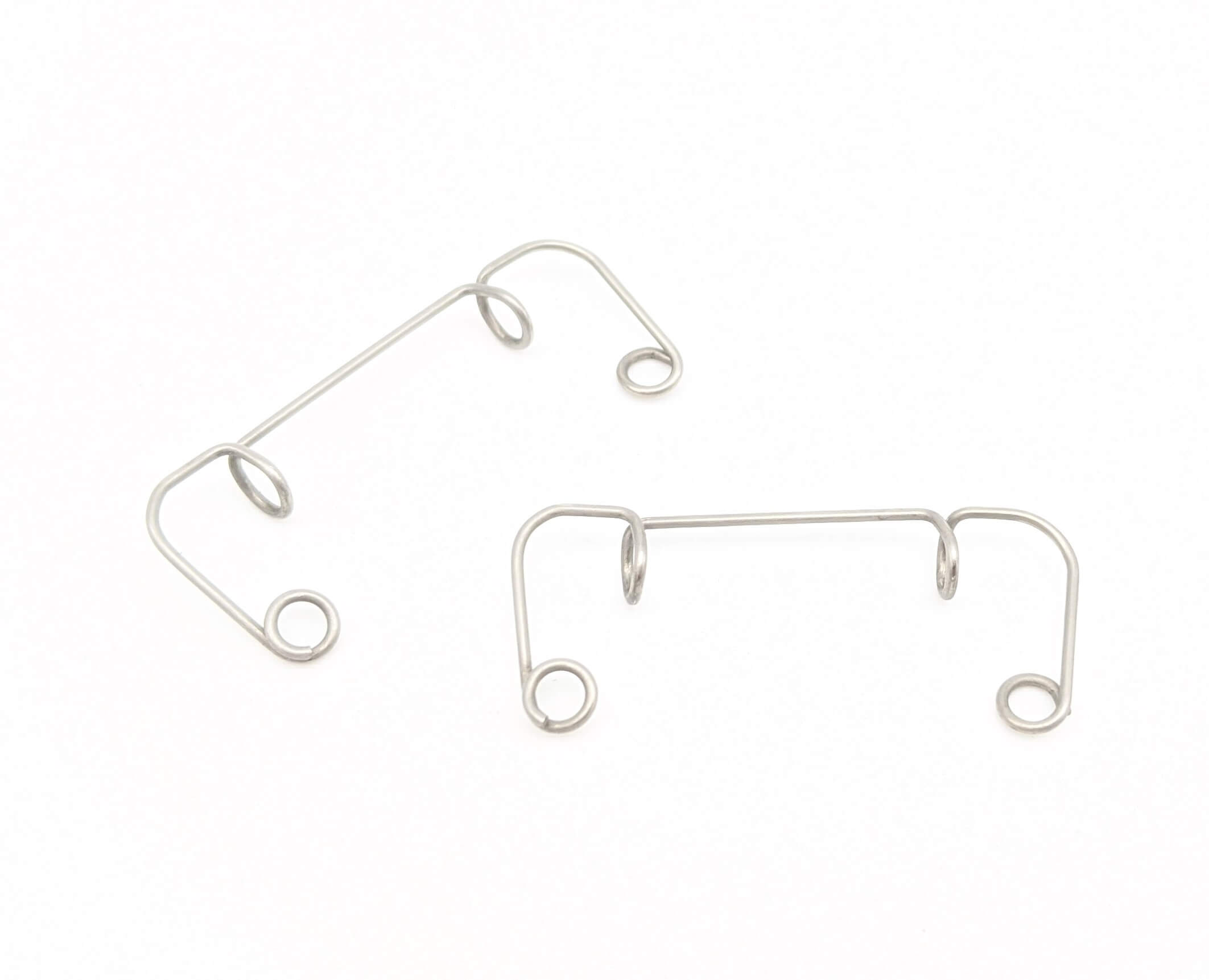

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion spring suspension, a unique and versatile system, utilizes the twisting force of torsion springs to support and control the movement of various components. This system is a fascinating blend

Torsion spring suspension, a unique and versatile system, utilizes the twisting force of torsion springs to support and control the movement of various components. This system is a fascinating blend of physics and engineering, offering distinct advantages in diverse applications, from automotive engineering to aerospace design. In this exploration, we'll delve into the heart of torsion spring suspension, unraveling its working principles, exploring its diverse applications, and uncovering the advantages that make it a standout choice in many scenarios. Let's embark on this journey to understand this ingenious engineering marvel.

At its core, torsion spring suspension relies on the principle of torque. A torsion spring, unlike its compression or extension counterparts, is designed to resist twisting forces. When a torque is applied, it stores energy by deflecting through an angle, much like a coiled-up rubber band. This stored energy is then released as the spring returns to its original position, providing a restoring force.

In a torsion spring suspension system, this twisting action is harnessed to support and control the movement of various components. Imagine a car's suspension system. A torsion bar, a long, thick spring, is anchored at one end and connected to the vehicle's chassis at the other. When the wheel encounters a bump, the torsion bar twists, absorbing the impact. As the wheel returns to its original position, the stored energy in the twisted torsion bar is released, pushing the wheel back up.

Torsion spring suspension boasts several compelling advantages over traditional spring systems, making it a popular choice in a wide range of applications. Here's a closer look at these benefits:

1. Space Efficiency: One of the most notable advantages of torsion spring suspension is its ability to save valuable space. Torsion springs can be compactly designed, tucked away in tight areas, making them ideal for vehicles, appliances, and other systems where space is at a premium. They offer a high spring constant in a small package.

2. Versatility: Torsion spring suspension can be tailored to meet a wide range of load requirements. The spring's stiffness can be adjusted by altering its length, diameter, and material properties. This versatility allows engineers to fine-tune the suspension for specific applications, from delicate mechanisms to heavy-duty equipment.

3. Durability and Reliability: Torsion springs are known for their resilience and ability to withstand significant loads without permanent deformation. Their simple design, devoid of complex moving parts, contributes to their long-term reliability. They are known for their low maintenance requirements.

The ingenuity of torsion spring suspension shines in various fields, each leveraging its unique characteristics to enhance performance and reliability.

1. Automotive Engineering: Torsion bars, a type of torsion spring, are a common sight in automotive suspension systems. They offer a simple, robust solution for handling loads and providing a smooth ride. Torsion bar suspension systems are particularly well-suited for trucks and off-road vehicles, where heavy loads and rough terrain are encountered.

2. Aerospace Design: Torsion springs play a crucial role in aerospace applications, particularly in aircraft landing gear. They provide a reliable and efficient way to absorb landing shock and ensure smooth ground handling. Their compact design and lightweight construction make them an ideal choice for aircraft.

3. Industrial Equipment: Torsion spring suspension is widely employed in industrial machinery and equipment. From heavy-duty cranes to precision manufacturing machines, these springs provide reliable support, shock absorption, and control. They are also used in conveyor systems, where they can provide smooth, consistent movement.

4. Appliance Design: Torsion springs find their way into appliances as well. For example, washing machines and dishwashers often use torsion springs to support their drums, ensuring smooth and efficient operation. These springs also contribute to the smooth and quiet operation of refrigerator doors and other appliance components.

5. Medical Devices: Even in the medical field, torsion springs play a vital role. They are used in various medical devices, such as surgical instruments and prosthetic limbs, providing precision movement, reliable support, and durability.

Torsion spring suspension is constantly evolving, with advancements in materials and manufacturing techniques leading to even more innovative and efficient designs. As demand for lightweight, durable, and space-efficient solutions continues to grow, torsion spring suspension is poised to play an even greater role in various industries. From high-performance automobiles to advanced medical devices, its versatility and reliability make it a valuable tool for engineers and designers seeking to create groundbreaking products.

In conclusion, torsion spring suspension stands as a testament to the elegance and practicality of engineering. Its ability to harness the power of torque to provide support, control, and shock absorption makes it a valuable asset in diverse applications. As technology advances, torsion spring suspension continues to evolve, promising even more innovative and groundbreaking designs in the years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.