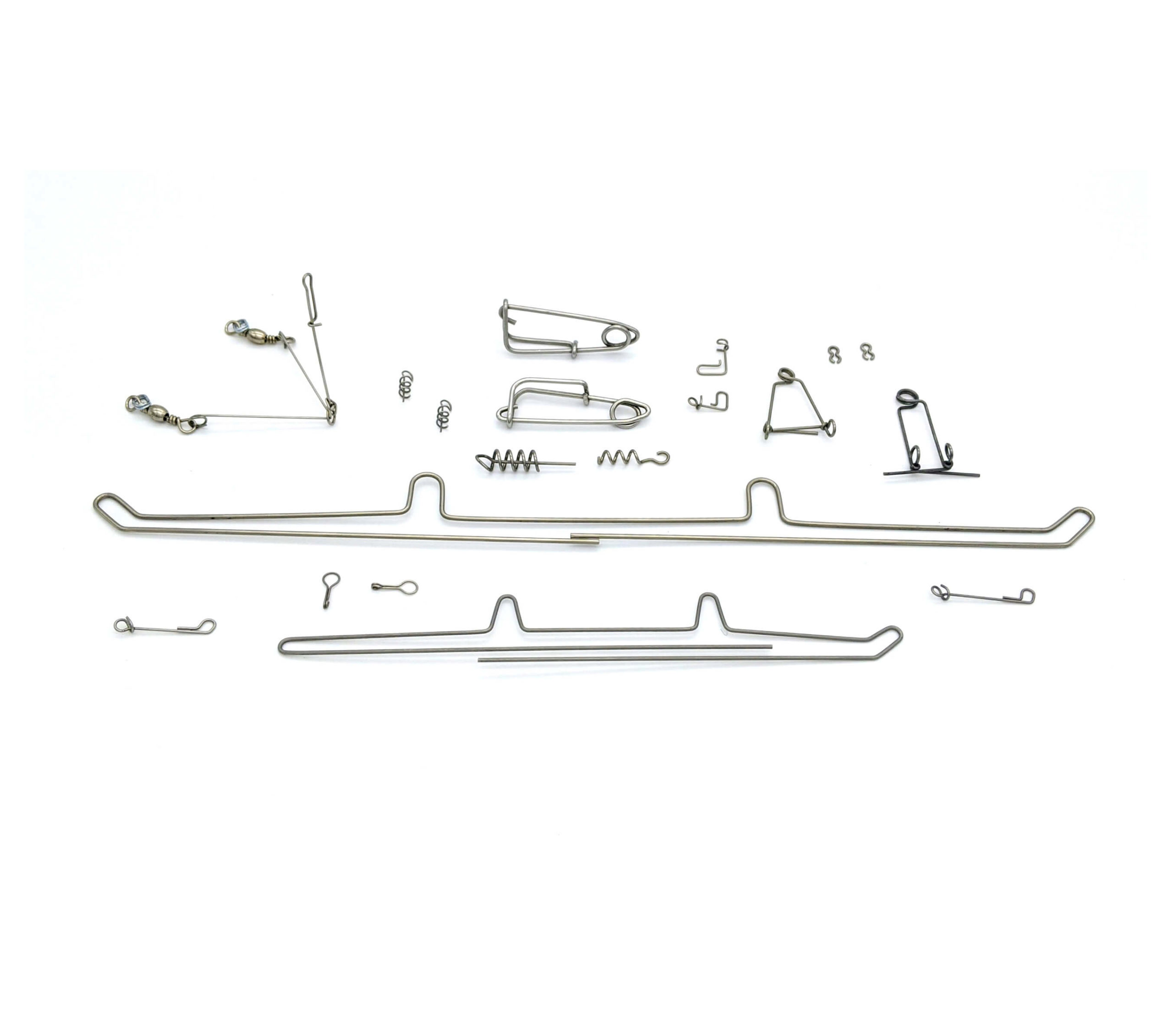

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Choosing the right torsion spring for your application can be a tricky task, but it doesn't have to be. This comprehensive guide will help you navigate the ins and outs

Choosing the right torsion spring for your application can be a tricky task, but it doesn't have to be. This comprehensive guide will help you navigate the ins and outs of torsion springs, including how to understand size charts, select the appropriate spring, and ensure proper installation. Whether you're a seasoned engineer or a DIY enthusiast, we've got you covered.

Torsion springs, unlike compression or extension springs, work by storing energy when twisted. They exert a torque, or rotational force, proportional to the angle they're twisted. You'll find them in various applications, from simple door hinges and garage door openers to complex mechanical systems in machinery and automotive components.

Torsion spring size charts are essential tools for choosing the right spring for your application. These charts typically list important parameters such as:

Navigating a torsion spring size chart is straightforward. Here's a general approach:

Choosing the right spring is crucial for its longevity and the proper function of your application. Here are some helpful tips:

Once you've selected your torsion spring, proper installation is essential for optimal performance and safety.

You can find reliable torsion spring size charts from these sources:

Torsion spring size charts are valuable resources for selecting and applying these essential mechanical components. By understanding the different parameters and using a chart effectively, you can ensure that your torsion spring is perfectly suited for your application. Remember to always prioritize safety and proper installation for optimal performance and longevity.

Choosing the right torsion spring is key to making your project a success. By understanding the information presented in this guide, you'll be well equipped to navigate the world of torsion spring size charts and select the perfect spring for your needs. Remember to always consult with a professional engineer for critical applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.