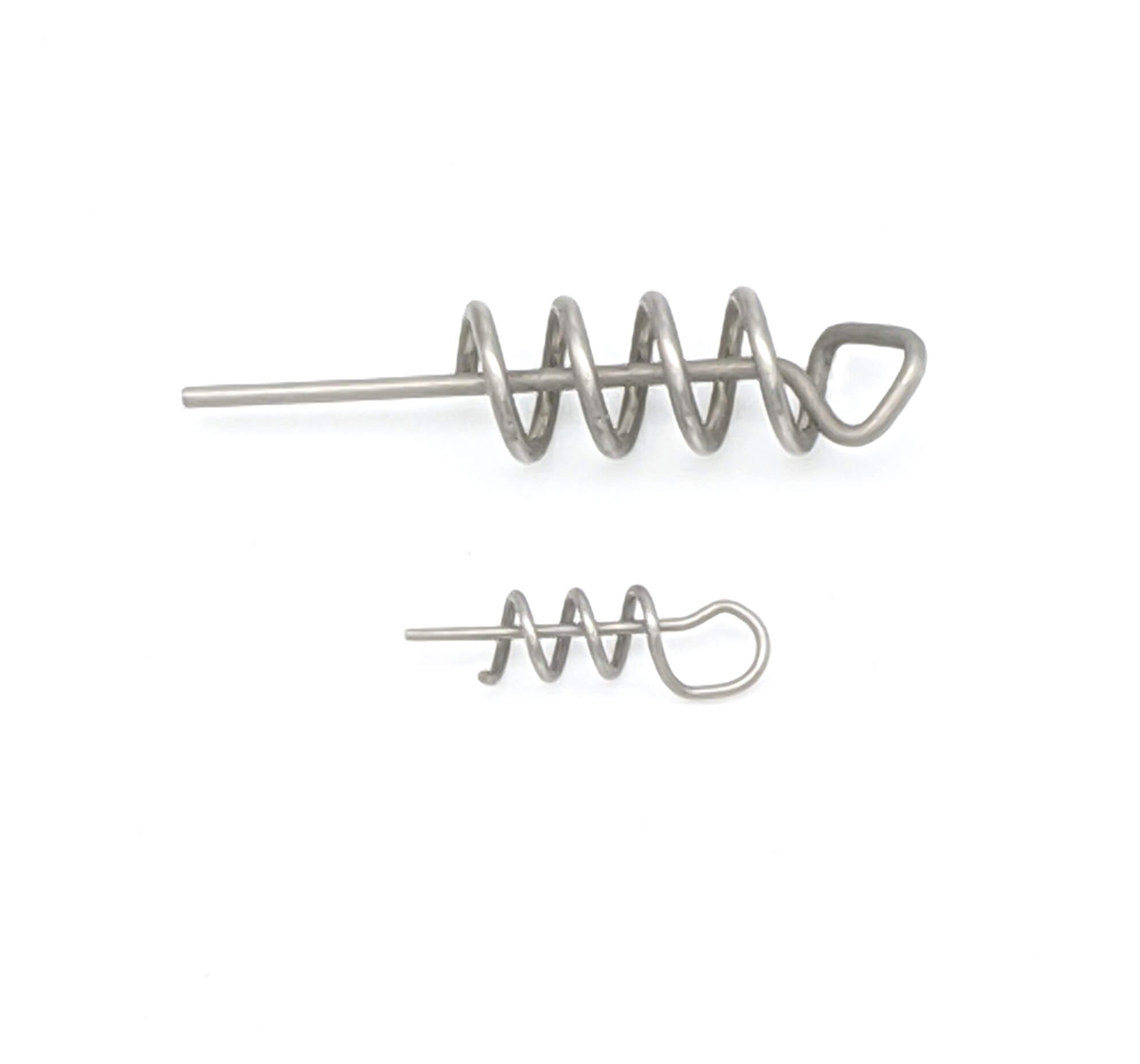

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, those coiled wonders that transform twisting force into stored energy, are everywhere around us, powering everything from door hinges and garage doors to watch mechanisms and car suspensions.

Torsion springs, those coiled wonders that transform twisting force into stored energy, are everywhere around us, powering everything from door hinges and garage doors to watch mechanisms and car suspensions. But selecting the right torsion spring for your application can be a daunting task. Enter the torsion spring chart, a powerful tool that can help you navigate the intricacies of spring selection and find the perfect match for your needs.

Torsion springs, as the name suggests, are designed to work under twisting forces. They are typically made of coiled wire, and when twisted, they store energy, resisting the twisting force and returning to their original position when released. Unlike their counterparts, tension and compression springs, which work under pulling and pushing forces, torsion springs are all about the twist.

The heart of a torsion spring lies in its ability to resist the twisting force and generate a counteracting torque. This resistance is known as the spring's 'rate,' which is measured in units of torque per angle of twist. Think of it as the spring's 'stiffness': a higher rate indicates a stiffer spring, requiring more force to twist.

Torsion spring charts, often referred to as 'spring selection charts,' are invaluable tools for engineers, designers, and anyone involved in choosing the right spring for their application. They offer a concise and organized way to understand the various parameters involved in spring selection, making the process much smoother and less prone to errors.

Imagine trying to choose the right spring without a chart. You'd be wading through a sea of data on wire diameter, coil diameter, number of coils, material properties, and more. It's like searching for a needle in a haystack! A well-designed torsion spring chart lays everything out in a clear, visual manner, allowing you to quickly compare different springs and make informed decisions.

A comprehensive torsion spring chart typically includes the following essential information:

Not all torsion spring charts are created equal. Some are designed for specific applications, while others offer a broader range of options. Look for a chart that provides a clear and comprehensive overview of the parameters relevant to your project.

Navigating a torsion spring chart may seem daunting at first, but with a bit of practice, you'll be able to select the right spring like a pro. Here's a step-by-step guide:

Remember, the torsion spring chart is a valuable tool, but it's not a substitute for sound engineering judgment. Always double-check the selected spring's suitability for your application, and if in doubt, consult with a spring specialist.

Torsion spring charts offer a fantastic starting point, but they are only part of the story. Here are some additional tips to ensure you're on the right track:

By following these tips and using a torsion spring chart as your guide, you'll be well on your way to selecting the perfect spring for your application. It's a process that demands careful attention to detail, but the rewards are significant: a spring that performs as expected, contributing to a successful design.

Torsion spring charts are your best friends when it comes to navigating the world of springs. They offer a visual and organized way to understand the various parameters involved in spring selection, making the process efficient and accurate. Remember, the chart is a tool to help you make informed decisions, and it's always wise to seek expert advice if you have any doubts. So, embrace the power of torsion spring charts and unlock the potential of these remarkable devices.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.