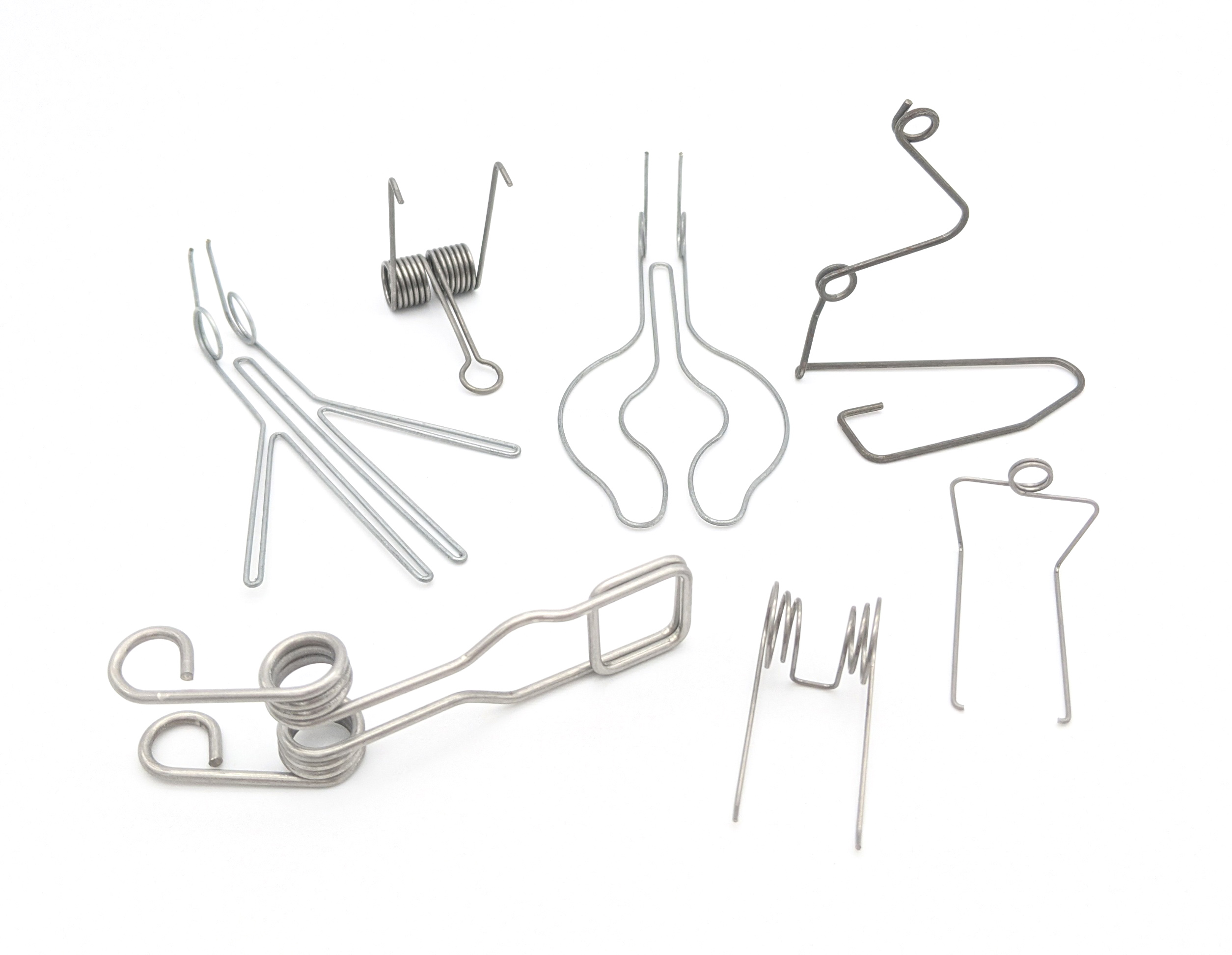

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion springs, often overlooked in the vast world of mechanical components, play a crucial role in numerous applications. From everyday household items to sophisticated industrial machinery, these springs provide a

Torsion springs, often overlooked in the vast world of mechanical components, play a crucial role in numerous applications. From everyday household items to sophisticated industrial machinery, these springs provide a twisting force that drives countless mechanisms. To fully grasp the potential of torsion springs, it's essential to understand their behavior and how they are classified. This comprehensive guide dives deep into torsion spring charts, demystifying their structure and providing insights into their applications.

Torsion springs are a type of spring designed to store and release energy through twisting or rotational motion. Unlike tension or compression springs that exert force along a linear axis, torsion springs generate torque when subjected to a twisting force. They are typically made of coiled wire, and the twisting action is applied along the spring's axis, causing it to wind or unwind.

Torsion spring charts are indispensable tools for engineers and designers seeking to select the right spring for their specific application. These charts provide a wealth of information about the characteristics of various torsion springs, enabling informed decisions about their suitability for a given project.

Torsion spring charts usually include the following key parameters:

Torsion spring charts often utilize graphs or tables to illustrate the relationship between various parameters. For instance, a graph might show the torque generated by a spring as a function of its deflection angle. This allows designers to determine the spring's behavior under different loading conditions. Another common representation might be a table listing the spring rate for various wire diameters, coil diameters, and numbers of coils. This provides quick reference for selecting the appropriate spring based on the desired stiffness.

Torsion spring charts are widely used across various industries:

While torsion spring charts provide valuable insights, it's essential to consider additional factors beyond the listed parameters. These factors include:

Torsion spring charts are invaluable tools for engineers and designers seeking to utilize these powerful components. They provide a wealth of information about the characteristics of various springs, aiding in selecting the optimal spring for specific applications. Understanding the parameters listed on these charts and considering other crucial factors beyond the charts ensures the successful integration of torsion springs into your designs, driving functionality and reliability across countless applications.

By harnessing the power of torsion spring charts and factoring in additional considerations, engineers and designers can confidently implement these versatile components into their designs. From everyday household items to sophisticated industrial machinery, torsion springs play a vital role in driving the world around us. Understanding the nuances of these springs opens doors to countless possibilities, enabling the creation of innovative and reliable products that enhance our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.