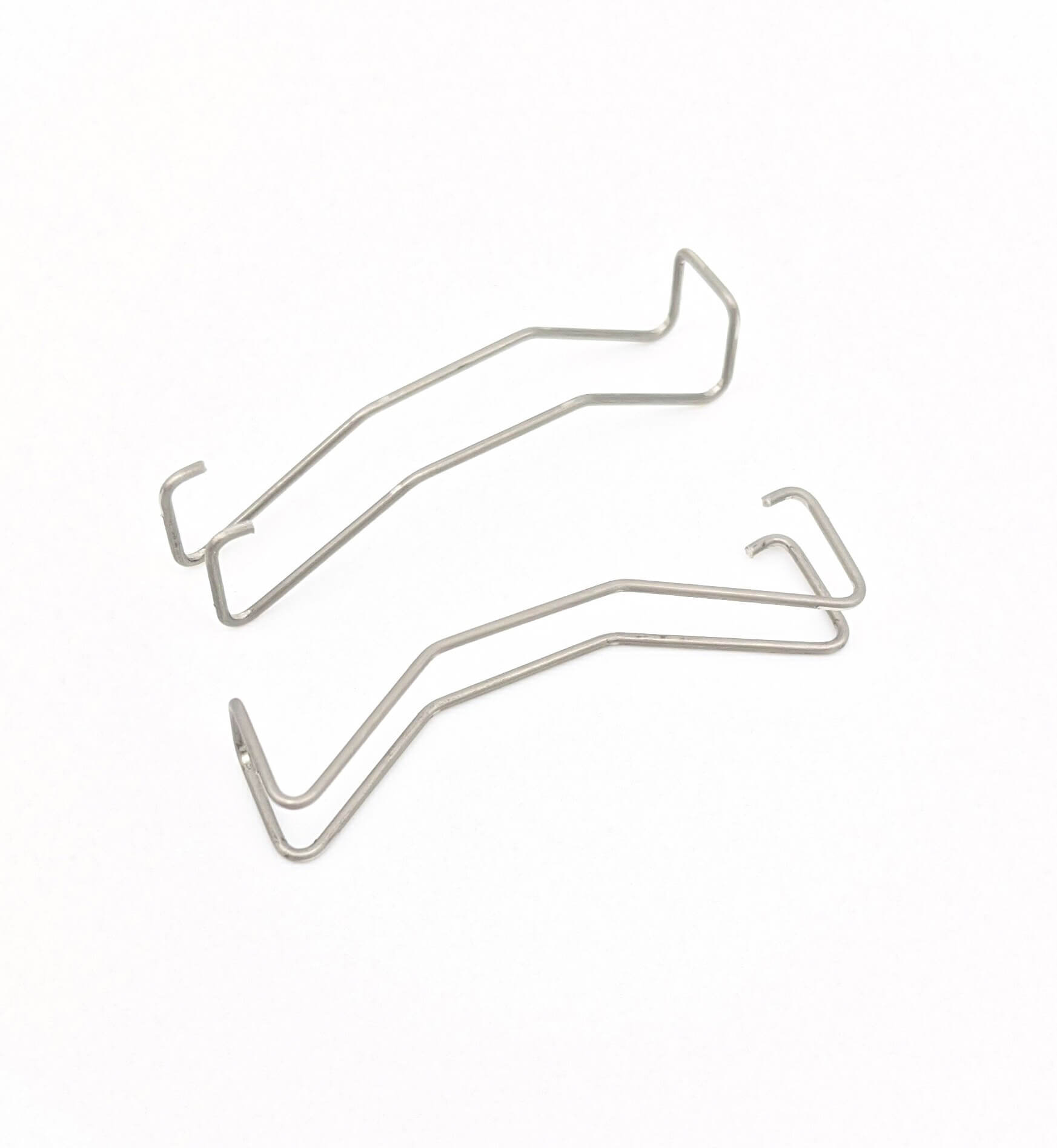

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

A torsion spring chart is a valuable tool for engineers, designers, and anyone working with torsion springs. It provides a visual representation of the relationship between torque and angular deflection,

A torsion spring chart is a valuable tool for engineers, designers, and anyone working with torsion springs. It provides a visual representation of the relationship between torque and angular deflection, allowing you to quickly select the right spring for your application. This comprehensive guide delves into the intricacies of torsion springs, exploring their construction, characteristics, applications, and how to effectively utilize a torsion spring chart for optimal spring selection. Whether you're a seasoned professional or a curious beginner, this article aims to equip you with the knowledge to confidently navigate the world of torsion springs.

Torsion springs, as the name suggests, are designed to resist twisting or torsional forces. They are typically coiled or helical springs that store energy when twisted and release it when allowed to unwind. Unlike compression or tension springs, which operate along an axis, torsion springs work by rotating around an axis. This unique characteristic makes them suitable for a wide range of applications requiring rotational force control.

A torsion spring chart is essentially a graph that plots the torque (rotational force) exerted by a torsion spring against its angular deflection (the amount it twists). It's a visual representation of the spring's load-deflection relationship. This chart is crucial for selecting the right spring for a specific application. Here's how to interpret a torsion spring chart:

* **Torque (Y-axis):** This axis represents the amount of rotational force the spring exerts. It's typically measured in units like Newton-meters (N·m) or inch-pounds (in·lb).

* **Angular Deflection (X-axis):** This axis represents the angle through which the spring rotates when subjected to a torque. It's usually measured in degrees or radians.

By analyzing the curve on the chart, you can determine several important factors:

* **Spring Rate:** The slope of the curve represents the spring rate, which is the change in torque per unit change in angular deflection. A steeper slope indicates a higher spring rate, meaning the spring exerts more force for the same amount of twist. Conversely, a flatter slope signifies a lower spring rate.

* **Operating Range:** The chart defines the range of angular deflections and torques for which the spring operates effectively. Beyond this range, the spring's performance may be compromised.

* **Maximum Torque:** The maximum torque point on the chart indicates the maximum rotational force the spring can withstand before it reaches its yield strength or fails. It's essential to operate the spring within this limit to prevent damage.

Several factors influence the shape and characteristics of a torsion spring chart, making it essential to consider them during spring selection:

* **Wire Diameter:** A thicker wire diameter results in a higher spring rate and increased torque capacity. Conversely, a thinner wire will have a lower spring rate and reduced torque capability.

* **Spring Index:** The ratio of the coil diameter to the wire diameter is known as the spring index. A higher spring index generally results in a lower spring rate, while a lower spring index leads to a higher spring rate.

* **Number of Coils:** The number of coils in the spring significantly influences the spring rate. More coils lead to a higher spring rate, while fewer coils result in a lower spring rate.

* **Material:** The type of material used for the spring plays a crucial role in determining its stiffness, strength, and durability. Materials like spring steel, stainless steel, and phosphor bronze are commonly used for torsion springs.

Torsion spring charts are invaluable tools across various industries and applications, providing vital information for:

* **Product Design:** Engineers and designers utilize the chart to select the right spring for their specific product requirements, ensuring optimal functionality and performance.

* **Manufacturing:** Manufacturers rely on torsion spring charts to control the manufacturing process, ensuring springs meet desired specifications and tolerances.

* **Quality Control:** The charts aid in quality control by providing a benchmark to compare actual spring performance against design specifications.

* **Troubleshooting:** When facing issues with a spring-based system, the chart helps pinpoint potential problems, like spring fatigue or improper selection.

Selecting the correct torsion spring for your application is critical. Consider these factors:

* **Torque Requirements:** Determine the amount of rotational force required for your application. The torsion spring chart helps you identify springs that meet or exceed those needs.

* **Angular Deflection Range:** Establish the maximum and minimum angles through which the spring must rotate. The chart helps you select a spring with a suitable operating range.

* **Spring Rate:** The spring rate, often expressed as torque per degree, determines the stiffness of the spring. Choose a spring rate that matches your application's force requirements.

* **Space Constraints:** Factor in the available space for the spring, considering its coil diameter and length. The chart assists in selecting a spring that fits within those constraints.

* **Material Properties:** The material's properties, such as its strength and corrosion resistance, are essential considerations. The chart may provide information on available materials and their characteristics.

A torsion spring chart is a powerful tool for understanding and selecting the right torsion spring for any application. By comprehending the factors influencing spring characteristics and navigating the chart effectively, you can confidently choose a spring that meets your specific needs, leading to efficient and reliable spring-based systems. Remember, a proper understanding of torsion springs and their charts empowers you to make informed decisions, ensuring optimal performance and longevity for your projects.

In conclusion, the torsion spring chart is an indispensable guide for professionals involved in design, manufacturing, and engineering. It provides a visual and quantitative understanding of the spring's behavior, allowing you to select the perfect spring for your application. By understanding the factors influencing spring performance and utilizing the chart effectively, you can optimize your spring selection process, leading to improved efficiency and reliability in your products and systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.