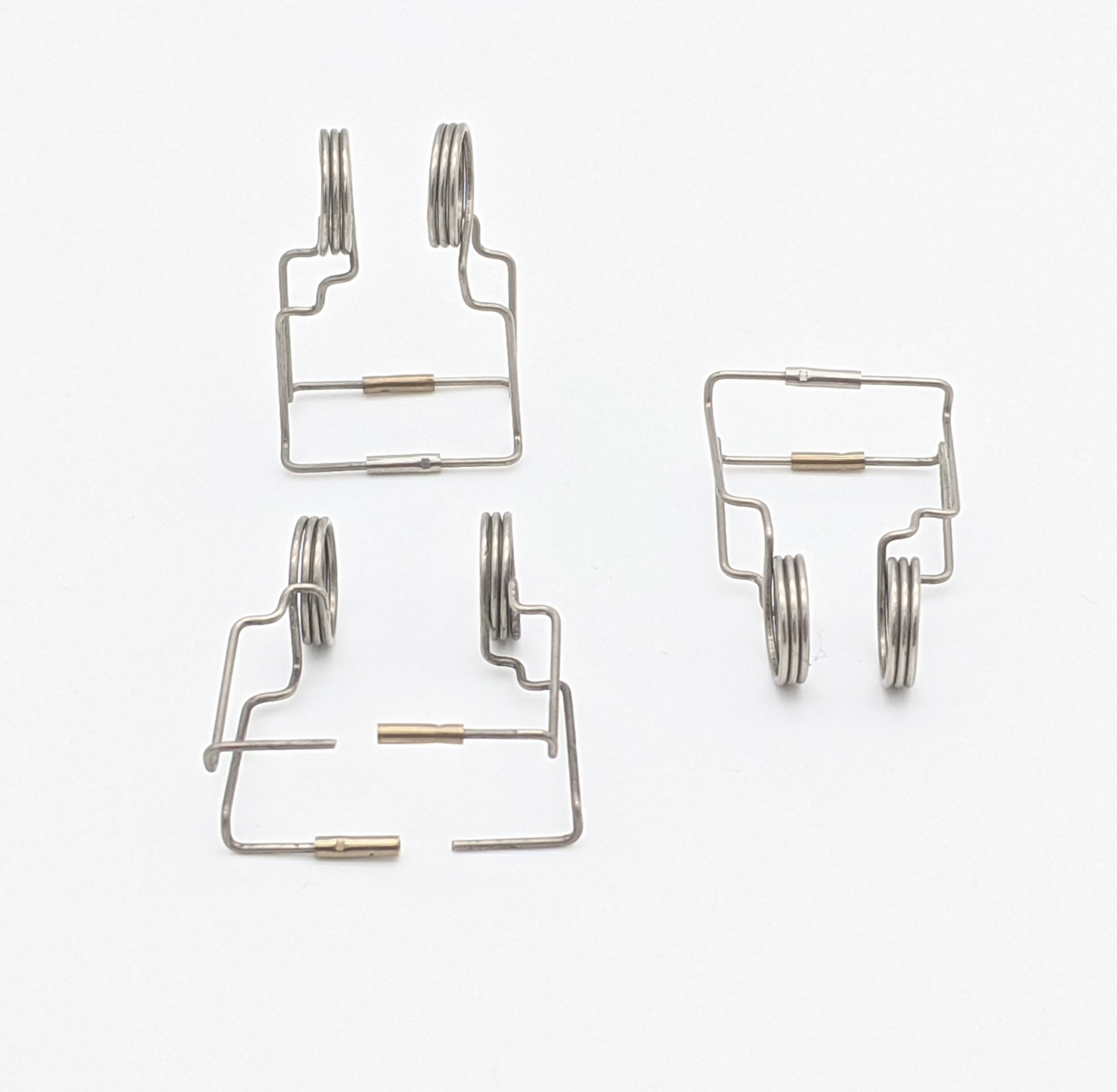

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Torsion bar springs, with their unique twisting action and remarkable strength, are essential components in various engineering applications. They're not just some obscure mechanical component; they're quietly but powerfully working

Torsion bar springs, with their unique twisting action and remarkable strength, are essential components in various engineering applications. They're not just some obscure mechanical component; they're quietly but powerfully working away, ensuring smooth operation and safe performance in countless devices and systems. From the suspension of your car to the intricate workings of a watch, torsion bar springs play a crucial role, often unseen but always vital. Let's delve into the world of torsion bar springs and uncover their amazing potential.

Torsion bar springs, unlike their more common helical spring counterparts, are designed to store and release energy through twisting or torsional deformation. Imagine a sturdy metal bar, fixed at one end and free to rotate at the other. When you apply a force that tries to twist this bar, it resists, storing potential energy. This stored energy is released when the twisting force is removed, causing the bar to return to its original position. This is the fundamental principle behind torsion bar springs.

At the heart of a torsion bar spring lies a cylindrical rod or bar, usually made from high-strength steel. One end of the bar is fixed, often to a chassis or frame, while the other end is connected to the component that needs to be moved or controlled. When a force is applied to the free end of the bar, it twists, storing energy. The amount of twist, or angle of rotation, is directly proportional to the applied force. When the force is removed, the spring unwinds, returning the connected component to its original position.

Torsion bar springs offer several advantages over other spring designs, making them a popular choice in various applications. Here are some key benefits:

The versatility of torsion bar springs makes them suitable for a wide range of applications, from automotive suspension systems to precision machinery. Some of the most common applications include:

While the basic principles remain the same, torsion bar springs come in different configurations and materials to suit specific applications. You might encounter:

Torsion bar springs are a testament to the power and ingenuity of mechanical engineering. Their ability to store and release energy through twisting motion makes them an invaluable component in a wide array of applications. They silently work behind the scenes, contributing to the smooth operation and reliable performance of numerous devices and systems. From the suspension of our cars to the intricate workings of precision instruments, torsion bar springs are a force to be reckoned with, and their presence continues to shape the world around us.

As we've explored the world of torsion bar springs, we've learned that these seemingly simple components play a critical role in many facets of our lives. Their unique twisting action, combined with their durability and versatility, makes them a vital part of modern engineering. So, the next time you're driving, glancing at a clock, or using a piece of machinery, remember the unseen force of torsion bar springs working away, ensuring reliable performance and smooth operation.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.